Introduction: Why Accurate Mechanical Seal Measurement Matters

Correct mechanical seal sizing is one of the most critical factors in ensuring reliable pump operation. Even a high-quality mechanical seal will fail prematurely if shaft size, seal chamber dimensions, or seal face measurements are incorrect.

This practical mechanical seal size guide explains how to accurately measure shaft diameter, seal chamber, and seal face dimensions, helping you avoid leakage, installation errors, and costly downtime — especially when replacing OEM seals or sourcing aftermarket alternatives.

Step 1: Measuring the Shaft Diameter

The shaft diameter is the most fundamental measurement for mechanical seal selection.

How to Measure:

-

Use a vernier caliper or micrometer

-

Measure the shaft at the seal installation location

-

Take multiple readings to confirm roundness

Key Tips:

-

Always measure in millimeters

-

Do not rely solely on pump nameplates

-

Check for shaft wear or scoring, which may affect seal fit

Common mistake: Using nominal shaft size instead of actual measured size.

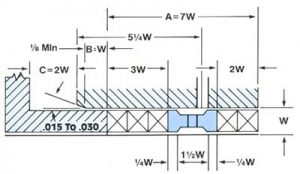

Step 2: Measuring the Seal Chamber (Stuffing Box)

The seal chamber (or stuffing box) must provide sufficient space and alignment for proper seal operation.

Critical Seal Chamber Dimensions:

-

Chamber bore diameter

-

Chamber depth

-

Available axial space

-

Flush port location

How to Measure:

-

Measure the inside bore using an internal caliper

-

Measure depth from the gland face to shaft shoulder

-

Confirm any step or recess inside the chamber

Insufficient chamber depth is a common cause of spring compression errors and face overheating.

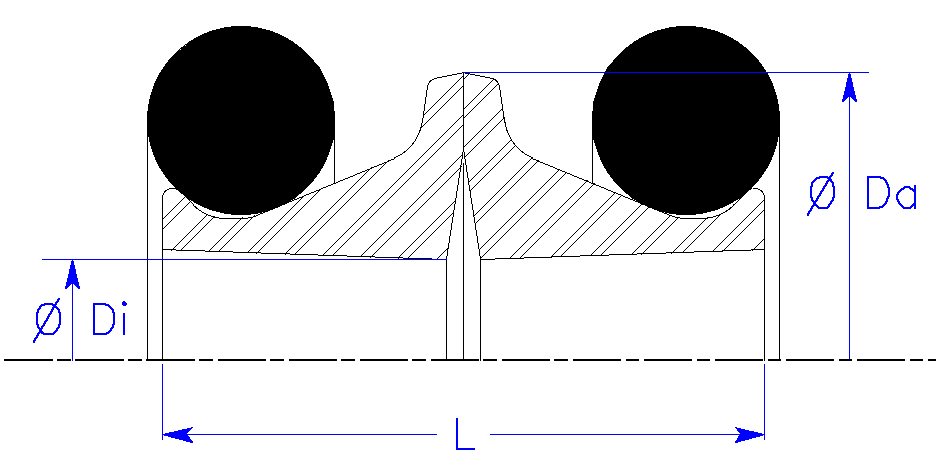

Step 3: Measuring the Seal Face Dimensions

Seal face dimensions determine load distribution, heat dissipation, and wear life.

Key Face Parameters:

-

Inner Diameter (ID)

-

Outer Diameter (OD)

-

Face width

-

Face flatness and finish

Practical Advice:

-

Face width must match operating pressure and speed

-

Higher pressure applications typically require wider seal faces

-

Always match face dimensions to OEM design when replacing seals

Step 4: Gland and Drive Features Verification

Beyond basic dimensions, correct seal performance depends on proper drive and gland alignment.

Check the following:

-

Drive collar position

-

Set screw location

-

Anti-rotation pin alignment

-

Gland bolt circle (for cartridge seals)

Incorrect drive alignment can cause face chipping, uneven wear, or immediate leakage.

Step 5: Special Considerations for Cartridge Mechanical Seals

Cartridge mechanical seals simplify installation but still require dimensional verification.

Confirm:

-

Shaft diameter compatibility

-

Cartridge axial length

-

Gland OD and bolt pattern

-

Seal chamber envelope clearance

Cartridge seals reduce installation errors, but incorrect sizing still leads to failure.

Common Mechanical Seal Measurement Mistakes

-

Measuring worn shafts without correction

-

Ignoring seal chamber depth

-

Mixing inch and metric units

-

Assuming OEM dimensions without verification

-

Skipping face width confirmation

Avoiding these mistakes significantly extends mechanical seal service life.

FAQ: Mechanical Seal Size and Measurement

Q1: Can I size a mechanical seal without drawings?

Yes. Accurate measurements using calipers and depth gauges are often sufficient.

Q2: Are shaft sizes standardized?

Not always. Actual shaft diameter may differ due to wear or manufacturing tolerance.

Q3: Should I measure the old seal or the pump?

Always prioritize pump measurements. Old seals may be worn or deformed.

Final Thoughts: Measurement Accuracy Determines Seal Reliability

Mechanical seal sizing is not a rough estimate — it is a precision task. Accurate measurement of shaft diameter, seal chamber, and seal face dimensions ensures proper sealing, stable operation, and long service life.

When in doubt, providing photos, sketches, or measurement tables will always result in better seal recommendations than assumptions.

Call to Action (CTA)

👉 Need help confirming mechanical seal dimensions?

Send us your pump model, photos, or measured data. Our technical team can assist with OEM replacement and custom mechanical seal sizing to ensure a perfect fit.