Many pump users rely on OEM mechanical seals specified by the original equipment manufacturer. However, OEM seals are often expensive, have long lead times, or become difficult to source due to regional restrictions, discontinued models, or supply chain issues.

The good news is that OEM mechanical seals can often be replaced without changing the original pump design, as long as compatibility is correctly evaluated. This article explains how to replace OEM mechanical seals safely and reliably while maintaining pump performance and operational integrity.

1. Why OEM Mechanical Seal Replacement Is Common

Replacing OEM mechanical seals is not a compromise—it is a practical decision made by many industrial users.

Common reasons include:

-

High OEM pricing

-

Long delivery times

-

Limited local availability

-

Obsolete or discontinued seal models

-

Regional sourcing restrictions

In most cases, pumps are designed around standardized sealing spaces, making reliable replacement possible.

2. Understanding OEM Mechanical Seal Design Parameters

Before selecting a replacement, it is critical to understand the key parameters of the original OEM seal. Replacement is not about copying appearance—it is about matching function.

Key parameters include:

-

Shaft size and seal chamber dimensions

-

Seal type (single, double, cartridge)

-

Operating pressure and temperature

-

Pump speed (RPM)

-

Process fluid characteristics

-

Installation method and axial setting

Accurate matching of these parameters ensures the replacement seal performs as intended.

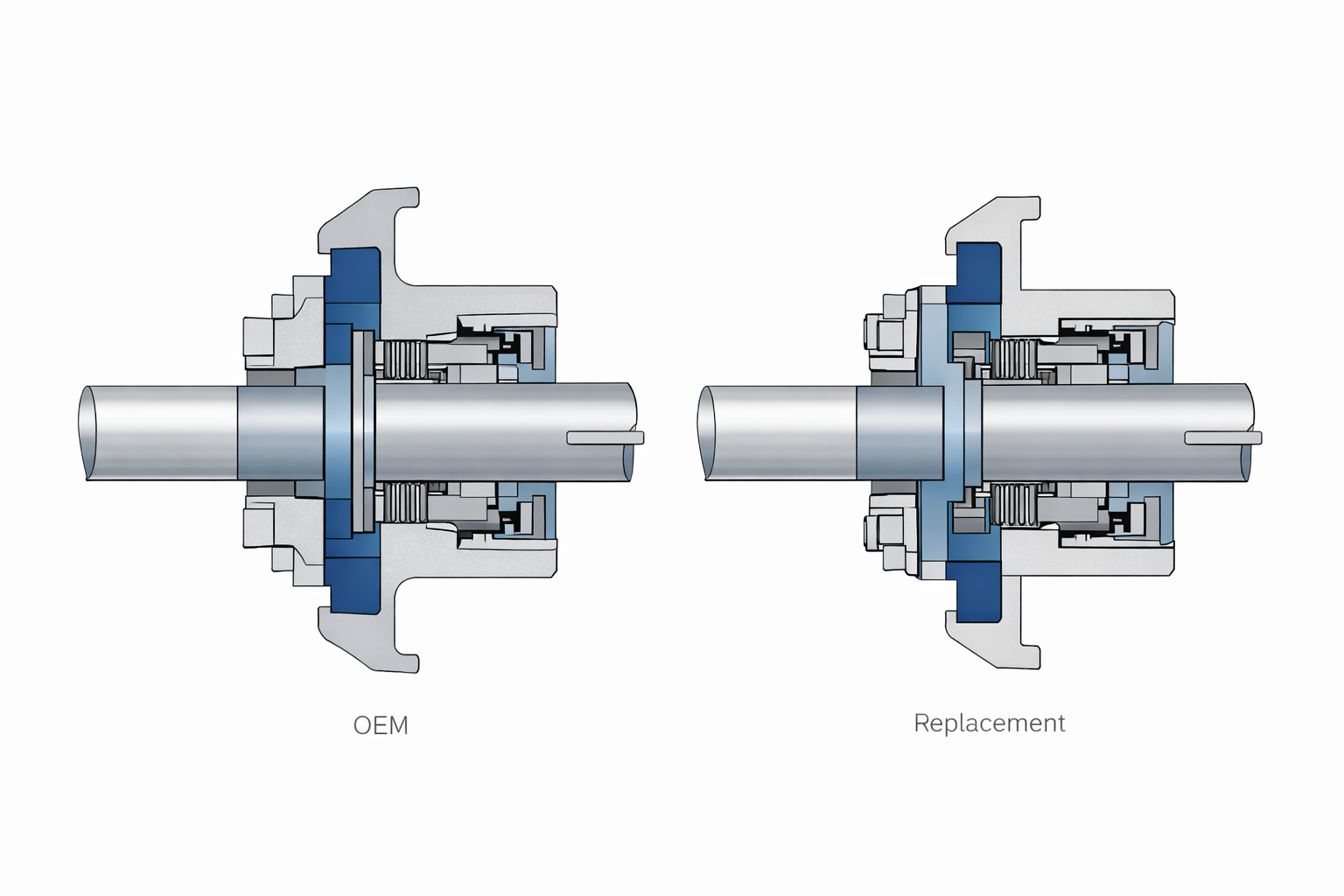

3. Cartridge vs Component Seals in OEM Replacement

In many OEM replacement cases, cartridge mechanical seals offer a safer and more reliable alternative.

Advantages of cartridge seals:

-

Pre-set axial dimensions

-

Reduced installation errors

-

Easier handling during maintenance

-

Consistent seal face alignment

When pump space allows, upgrading from a component seal to a cartridge seal can significantly reduce failure risk without modifying pump design.

4. Material Compatibility: More Important Than Brand

One common misconception is that OEM seals perform better simply because of the brand. In reality, material selection determines performance, not branding.

Critical material considerations:

-

Seal face materials (Carbon, SiC, TC)

-

Elastomers (NBR, FKM, FFKM)

-

Metal parts (SS304, SS316, Hastelloy)

A replacement seal with properly selected materials can meet or exceed OEM performance in the same operating conditions.

5. Installation Compatibility Without Pump Modification

A proper replacement seal should:

-

Fit the existing shaft and seal chamber

-

Use the same or compatible installation method

-

Require no changes to pump casing, cover, or piping

-

Maintain original flush or cooling arrangements

If pump modification is required, it usually indicates incorrect seal selection—not a limitation of replacement seals.

6. Common Risks When Replacing OEM Mechanical Seals

While OEM replacement is feasible, risks arise when evaluation is incomplete.

Common mistakes include:

-

Ignoring axial setting requirements

-

Overlooking dynamic shaft movement

-

Using incompatible elastomers

-

Focusing only on dimensions, not operating conditions

These mistakes can lead to early leakage, vibration issues, or shortened seal life.

7. When OEM Replacement Is Not Recommended

OEM replacement may not be suitable if:

-

The pump operates near extreme limits

-

The original seal uses proprietary designs

-

The application involves highly specialized processes

-

Seal failure could result in safety or environmental hazards

In such cases, direct OEM sourcing or custom-engineered solutions may be necessary.

8. Information Needed for Accurate OEM Seal Replacement

To ensure a reliable replacement, the following information is recommended:

-

OEM seal model or drawing (if available)

-

Pump model and manufacturer

-

Operating temperature and pressure

-

Process fluid description

-

Photos of the installed seal and seal chamber

This information allows suppliers to evaluate compatibility without trial-and-error.

Заключение

Replacing OEM mechanical seals without changing pump design is not only possible—it is widely practiced across industries worldwide. Success depends on correct technical evaluation, material compatibility, and installation discipline, not brand loyalty.

With proper selection, replacement mechanical seals can deliver reliable performance, reduced downtime, and significant cost savings—without altering the original pump design.

👉https://sakowit.com/cartridge-mechanical-seals-manufacturer/