In modern industrial operations, pump reliability is no longer measured by purchase cost alone. Today, companies evaluate equipment based on Total Cost of Ownership (TCO) — a combination of the seal’s purchase price, installation time, maintenance labor, spare parts, and production downtime.

This is where картриджные механические уплотнения outperform traditional component seals and packing. Their design offers fast installation, stable performance, and dramatically lower long-term operating costs. For industries seeking higher efficiency and reduced maintenance budgets, cartridge seals have become an essential upgrade.

1. What Drives TCO in Pump Sealing Systems?

The real cost of a sealing system includes:

-

Seal installation and alignment time

-

Frequency of replacement

-

Labor cost for maintenance

-

Leakage-related product loss

-

Unplanned shutdowns

-

Energy consumption due to friction or instability

Many factories still use traditional component seals or packing because the initial purchase price is lower. However, over a 1–3 year operating cycle, these options often lead to:

-

Frequent leakage

-

Faster wear

-

Higher labor cost

-

Unexpected failures

This makes the total lifecycle cost significantly higher.

2. Why Cartridge Mechanical Seals Reduce TCO

Cartridge mechanical seals are pre-assembled, factory-set units. The installer only needs to mount the cartridge and tighten the gland bolts — no measurement, no alignment, no risk of errors.

Key advantages:

✔ (1) Faster Installation = Lower Labor Cost

Traditional seals require 30–60 minutes of alignment.

A cartridge seal typically takes 5–10 minutes.

This alone reduces labor cost by up to 70%.

✔ (2) Virtually Eliminates Installation Errors

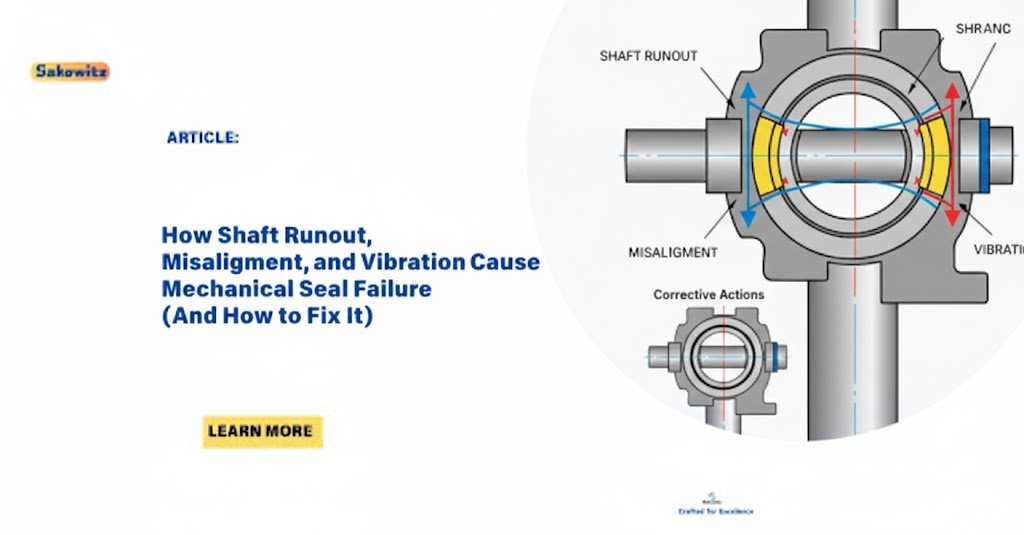

Most seal failures come from:

-

Wrong setting length

-

Misaligned faces

-

Shaft runout

-

Incorrect spring compression

Cartridge seals solve all of these issues because:

-

The compression is factory-preset

-

The rotating and stationary faces are aligned

-

The seal is shipped as a complete unit

Less installation error ⇒ longer seal life.

✔ (3) Reduced Leakage and Higher Operational Stability

Cartridge seals typically operate with:

-

More stable face pressure

-

Better heat dissipation

-

Effective secondary sealing elements

-

Higher tolerance to vibration and shaft movements

This greatly reduces product loss and contamination risk.

✔ (4) Longer Service Life = Fewer Shutdowns

Cartridge seals often last 2–4 times longer than packing and 1.5–2 times longer than standard single mechanical seals.

This lowers:

-

Maintenance frequency

-

Spare parts consumption

-

Unplanned downtime

For industries where every shutdown is extremely costly — such as petrochemical, food processing, power plants — cartridge seals are a high-return investment.

3. Real Industrial Applications with High TCO Savings

Cartridge mechanical seals are especially beneficial in:

-

Chemical reactors

-

Agitators & mixers

-

Slurry & wastewater pumps

-

High-temperature oil pumps

-

Pharmaceutical production lines

-

Food and beverage processing

Each of these industries faces long operating hours and strict leakage control — making TCO reduction even more critical.

4. Sakowitz Cartridge Seal Solutions (Recommended Models)

🔹 M481K – Ideal for Reactors & High-Temperature Processes

-

Handles extreme temperature and viscosity

-

Long service life reduces downtime

-

Suitable for chemical, resin, coating & polymer plants

🔹 125CLHG-12 Cartridge Seal

-

Easy installation for industrial pumps

-

Designed for demanding rotating equipment

🔹 150CBLHGZ-8 Cartridge Seal

-

Enhanced stability for heavy-duty mixing and agitation systems

Using these models, customers can reduce TCO by:

-

Extending seal life

-

Cutting maintenance hours

-

Avoiding shutdown-related financial loss

5. Case Example: A European Chemical Plant Reduced Costs by 38%

A customer operating a chemical reactor originally used packing seals and replaced them every 4–6 weeks due to leakage.

After switching to the M481K cartridge mechanical seal, they reported:

-

Seal life increased to 10–12 months

-

Maintenance time reduced by 80%

-

Annual downtime decreased by 120 hours

-

Total sealing cost dropped by 38%

This demonstrates the long-term financial advantage of upgrading to cartridge mechanical seals.

6. Conclusion: Cartridge Seals Are the Future of Cost-Efficient Pump Operation

As industries shift from low upfront cost to long-term cost optimization, cartridge mechanical seals provide:

-

Lower TCO

-

Higher reliability

-

Faster installation

-

Better safety

-

Longer lifespan

For factories seeking stable operation and higher production efficiency, upgrading to cartridge mechanical seals is one of the most effective investments.

📞 CTA

If you are looking for reliable cartridge mechanical seals for pumps, mixers, or reactors, contact us for technical suggestions or a quotation:

👉https://sakowit.com/cartridge-mechanical-seals-manufacturer/

Our engineering team will recommend the best solution for your operating conditions.