Mechanical seals have evolved significantly over the last decade. As industries demand higher reliability, lower maintenance costs, and safer operation, traditional component seals are no longer enough. Cartridge mechanical seals have rapidly become the preferred choice for modern pumps—especially in chemical processing, oil & gas, pharmaceuticals, wastewater treatment, food production, and high-pressure reactors.

This article explains why cartridge seals are dominating the global market, how they improve pump reliability, and why more engineering teams are replacing traditional packing and component seals with advanced pre-assembled cartridge units.

1. What Is a Cartridge Mechanical Seal?

A cartridge mechanical seal is a pre-assembled, pre-set sealing system that includes:

-

Seal faces

-

O-rings / secondary seals

-

Gland plate

-

Sleeve

-

Set screws

-

Alignment fixtures

Unlike component seals, all elements are already aligned and factory-calibrated. Installation requires no measurement, no push-setting, and no depth calculation.

Key Advantages:

-

Prevents installation errors

-

Standardized compression and face alignment

-

Faster replacement during shutdown

-

Ideal for inexperienced or rotating maintenance teams

2. Why Cartridge Seals Are the Future of Pump Reliability

(1) Zero Installation Mistakes — the #1 Failure Cause Eliminated

Research shows that more than 50% of seal failures come from incorrect installation.

Cartridge seals remove this risk completely because they come with:

-

Pre-set spring loads

-

Fixed face alignment

-

Locking mechanisms

-

Defined installation length

This makes them ideal for factories with limited on-site sealing expertise.

(2) Significantly Longer Service Life

Because the seal faces are aligned at the factory, running conditions are far more stable.

Cartridge seals maintain:

-

Better face balance

-

Lower heat generation

-

Reduced vibration sensitivity

-

Better performance under dry-running moments

This leads to longer MTBF (mean time between failures) and lower total cost of ownership.

(3) Excellent Performance Under High Pressure and High Temperature

Many of your high-end models—such as 125CLHG-12, 150CBLHGZ-8, Cartex DN, M481K variants—are built for challenging environments:

-

High-viscosity media

-

Chemicals

-

Solvents

-

High-temperature reactors

-

Питательные насосы высокого давления

-

Slurry or abrasive media

Cartridge seals are more stable because the structure prevents face distortion under pressure.

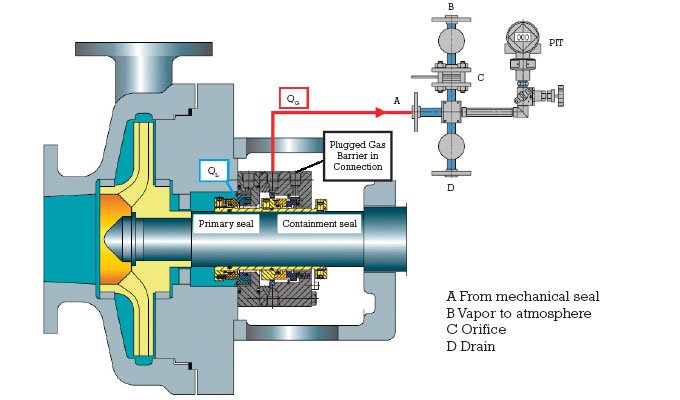

(4) Ideal for Hazardous, Toxic, or Flammable Media

In petrochemical and chemical plants, leakage control is critical.

Cartridge seals—especially double cartridge seals—allow:

-

Barrier fluid circulation

-

Zero fugitive emissions

-

API 682 compliance

-

Better safety for operators

This is why they are widely used in hydrocarbon pumps, reactor mixers, and solvent recovery systems.

(5) Faster Maintenance — Reduce Downtime Costs

A skilled technician may spend hours installing a component mechanical seal.

Cartridge seal installation typically requires:

-

Position the gland

-

Tighten bolts

-

Remove setting clips

Total time: often < 10 minutes.

For factories with frequent shutdowns, this saves thousands of dollars per year.

3. Applications Where Cartridge Seals Provide Maximum Value

Cartridge seals are now widely used in:

-

Chemical reactors (M481K series)

-

Oil & gas pumping units

-

Pharmaceutical mixing systems

-

Food & beverage processing lines

-

Wastewater and sludge pumps

-

Pulp and paper industry pumps

-

High-speed centrifugal pumps

-

Slurry and abrasive media pumps

Wherever reliability matters, cartridge seals outperform traditional designs.

4. Comparison: Cartridge Seal vs. Component Seal

| Feature | Уплотнение картриджа | Component Seal |

|---|---|---|

| Installation | Very easy, pre-set | Requires precise measurement |

| Failure risk | Very low | High (alignment issues, O-ring damage) |

| Downtime | Minimal | Long |

| Производительность | Stable under pressure | Sensitive to installation errors |

| Cost | Higher upfront | Lower upfront |

| Long-term cost | Much lower | Usually higher |

For engineering teams focused on safety + stability + long-term cost control → cartridge seals are the clear winner.

5. Sakowitz Cartridge Mechanical Seal Solutions

Sakowitz provides a full range of high-performance cartridge mechanical seals for industrial applications, including:

-

125CLHG-12 — High-pressure chemical pumps

-

150CBLHGZ-8 — Large reactors & mixers

-

Cartex DN — Standardized cartridge unit for general pumps

-

Custom cartridge seal manufacturing

-

API 682-compliant double cartridge seals

All products are made with advanced materials:

-

SiC/SiC

-

TC/TC

-

FKM / FFKM / EPDM

-

Stainless steel / Alloy 20 / Duplex steel

We support OEM customization and urgent delivery.

6. FAQ

Q1: Are cartridge seals more expensive?

Yes, but they save much more in downtime, failures, and maintenance.

Q2: Can cartridge seals replace packing?

Absolutely. They eliminate leakage, reduce friction, and improve pump life.

Q3: Do cartridge seals work for abrasive media?

Yes—especially when paired with SiC/SiC or TC/TC faces.

Q4: Can you customize sizes?

Yes, Sakowitz supports design + manufacturing for special pumps and mixers.

7.Call to Action

If you need a high-performance cartridge mechanical seal for your pump or reactor, contact Sakowitz for a quick quotation and technical support.

👉 Get a Quote: https://sakowit.com/mechanical-seal-landing-page/