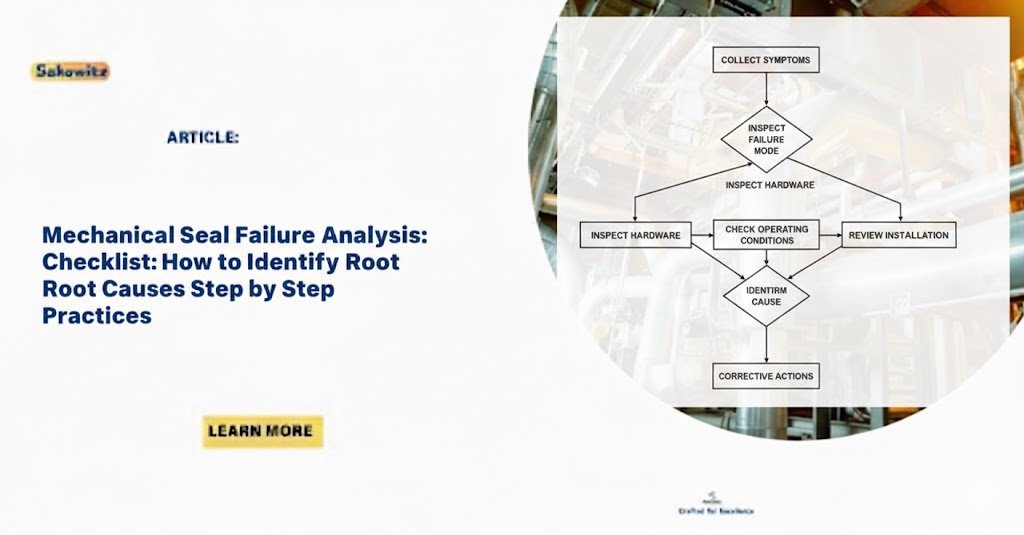

Mechanical Seal Failure Analysis: How to Identify Root Causes Step by Step

Mechanical seal failures are rarely “random.” In most cases, the seal is not the true problem—it is the first component that shows symptoms of a bigger system issue, such as dry running, misalignment, process contamination, unstable pressure/temperature, or incorrect support conditions. The biggest mistake many plants make is replacing the seal without identifying why it […]

Mechanical Seal Leakage: Common Causes, Diagnosis, and Solutions

Introduction: Why Mechanical Seal Leakage Happens More Often Than You Think Mechanical seal leakage is one of the most common problems in industrial pumps.Even a small leak can lead to equipment downtime, safety risks, product loss, and higher maintenance costs. Many users assume leakage means “the seal quality is poor”, but in reality, most leaks […]

How to Store and Handle Mechanical Seals Correctly (Avoid Shelf Damage and Installation Issues)

Introduction: Why Mechanical Seals Fail Before They Are Installed Mechanical seals are precision components, but many seal failures begin long before installation.Improper storage and careless handling can cause hidden damage that leads to leakage, shortened service life, or immediate failure after start-up. Common problems such as cracked seal faces, hardened elastomers, or distorted components are […]

Mechanical Seal Maintenance Checklist: Inspection, Start-Up, and Shutdown Best Practices

Introduction: Why Mechanical Seal Maintenance Matters More Than You Think Mechanical seals are precision components, but they operate in imperfect real-world conditions.Many premature seal failures are not caused by poor seal design, but by improper inspection, incorrect start-up procedures, or rushed shutdowns. A structured maintenance checklist helps: Prevent dry running Avoid thermal shock Reduce leakage […]

Mechanical Seal for Slurry or Abrasive Fluids: Design Tips to Reduce Face Wear

Introduction: Why Slurry Applications Destroy Mechanical Seals Faster Mechanical seals operating in slurry or abrasive fluids face one of the harshest sealing environments.Solid particles trapped between seal faces cause rapid abrasive wear, excessive heat generation, and premature leakage. In many slurry applications, seal failure is not caused by poor manufacturing quality—but by inappropriate seal design […]

Dry Running in Mechanical Seals: What Happens, How to Detect It, and How to Prevent It

Introduction: Why Dry Running Is One of the Fastest Seal Killers Dry running is one of the most destructive operating conditions for mechanical seals.Unlike gradual wear or chemical attack, dry running can destroy seal faces within seconds or minutes. Many seal failures labeled as “sudden” or “unexplained” are actually caused by short periods of dry […]

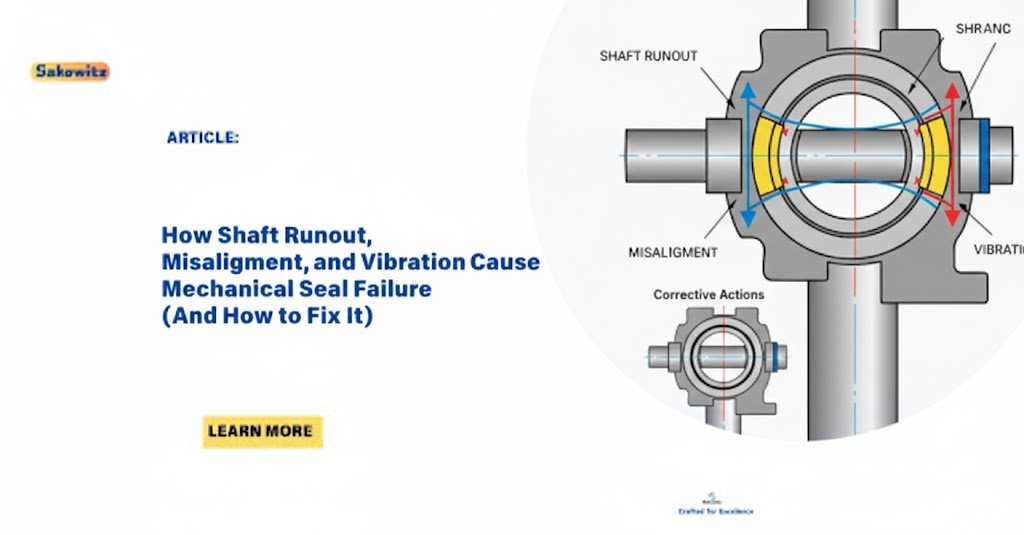

How Shaft Runout, Misalignment, and Vibration Cause Mechanical Seal Failure (And How to Fix It)

Introduction: Why “Perfect Seals” Fail in Real Operation Many mechanical seal failures are mistakenly blamed on seal quality or material selection.In reality, a large percentage of premature seal failures are caused by shaft runout, misalignment, and excessive vibration. Even the most advanced mechanical seal cannot survive long if the rotating system is unstable. This article […]

API Flush Plans for Mechanical Seals: Which Plan Prevents Leakage and Overheating?

Introduction: Why API Flush Plans Are Critical for Seal Reliability Mechanical seal failures are often caused not by the seal design itself, but by insufficient cooling, poor lubrication, or improper flush configuration.This is where API Flush Plans play a critical role. API flush plans define how fluids are supplied, circulated, or removed around the mechanical […]

Single vs Double Seal Support Systems: Barrier Fluid, Buffer Fluid, and What to Choose

Introduction: Why Seal Support Systems Matter Mechanical seal performance does not depend on the seal alone.In many industrial pump applications, seal support systems play a critical role in controlling temperature, lubrication, leakage, and safety. Understanding the difference between single seal systems, double seal systems, barrier fluids, and buffer fluids is essential for choosing the right […]

Mechanical Seal Materials Explained: Carbon vs Ceramic vs Silicon Carbide vs Tungsten Carbide

Introduction: Why Mechanical Seal Material Selection Is Critical Mechanical seal materials play a decisive role in seal performance, service life, and reliability. Even with the correct seal type and size, improper material selection can cause excessive wear, thermal cracking, chemical attack, or sudden leakage. This guide explains the four most commonly used mechanical seal face […]

Mechanical Seal Size Guide: How to Measure Shaft, Seal Chamber, and Face Dimensions

Introduction: Why Accurate Mechanical Seal Measurement Matters Correct mechanical seal sizing is one of the most critical factors in ensuring reliable pump operation. Even a high-quality mechanical seal will fail prematurely if shaft size, seal chamber dimensions, or seal face measurements are incorrect. This practical mechanical seal size guide explains how to accurately measure shaft […]

How to Select the Right Mechanical Seal for Your Pump Application

A Practical SEO Selection Guide Introduction: Why Mechanical Seal Selection Matters Selecting the right mechanical seal for your pump application is not just a technical decision — it directly affects equipment reliability, maintenance cost, downtime, and safety. An incorrect seal choice can lead to premature leakage, excessive wear, product contamination, or even catastrophic pump failure. […]