Water Pump Mechanical Seal Suppliers

Sakowitz designs and manufactures high-performance water pump mechanical seals for industrial, agricultural, and domestic pumping systems

— ensuring zero leakage, durability, and efficiency.

Water Pump Mechanical Seals – Function & Importance

Water Pump Mechanical Seal is a highly precise sealing device designed to prevent liquid from leaking along the pump shaft. It consists of moving ring, stationary ring, spring, and O-ring, etc. Through the close contact of the sealing surfaces at both ends, it achieves a “dynamic and leak-free sealing”. Unlike traditional packing seals, the mechanical seal can operate stably under higher pressure and speed, and significantly reduces wear and maintenance frequency.

This sealing method not only enhances the operational efficiency of the pump, but also extends the lifespan of the bearings and the motor. According to industry statistics, the overall maintenance period of a water pump system using mechanical seals can be increased by 30–50%.

Why Mechanical Seals Are Essential for Water Pumps

Mechanical seals are the key components that ensure the efficient and stable operation of water pumps. They can effectively prevent the leakage of the medium along the pump shaft, thereby reducing energy loss and maintaining stable system pressure. Compared with traditional packing seals, mechanical seals can operate at higher temperatures and pressures, significantly enhancing the overall reliability of the equipment.

High-quality mechanical seals can also protect the pump shaft and bearings from corrosion and wear, thereby extending the service life of the equipment. According to industry data, pumps with correctly configured mechanical seals can reduce the maintenance frequency by more than 40%, while improving operational efficiency.

Furthermore, mechanical seals have excellent adaptability to various media such as water, oil, and weak acids and bases, making them an indispensable core sealing solution in modern industrial and municipal systems.

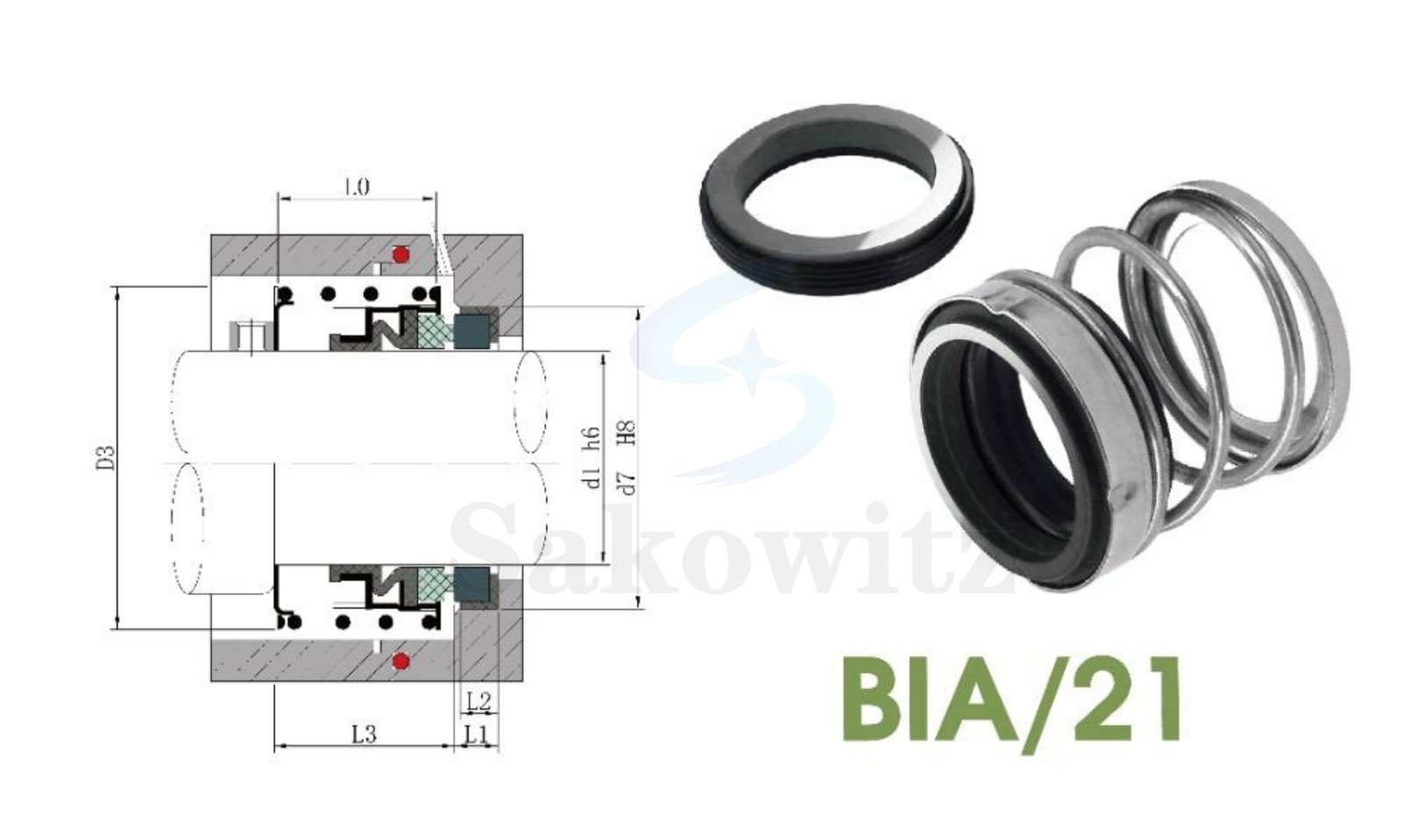

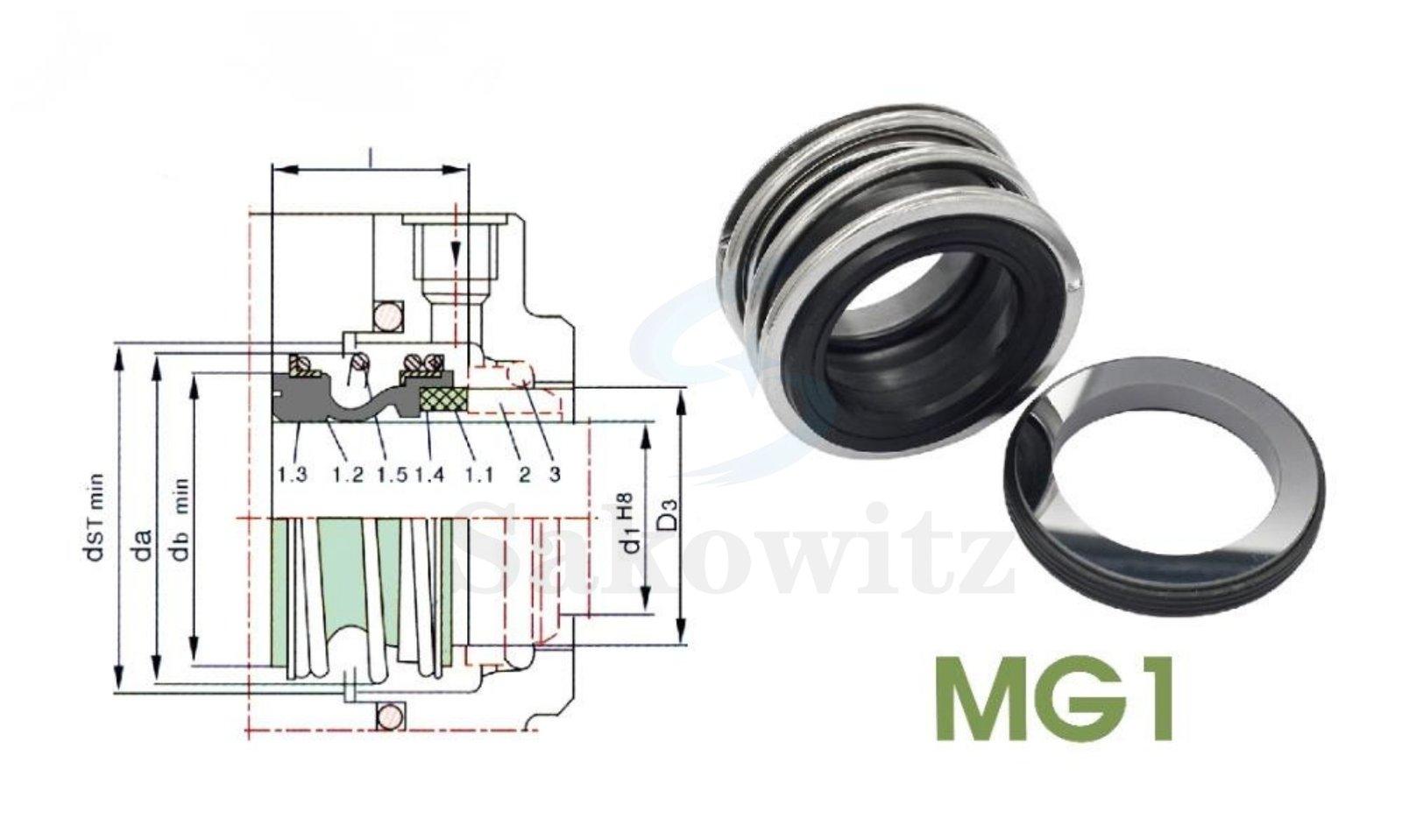

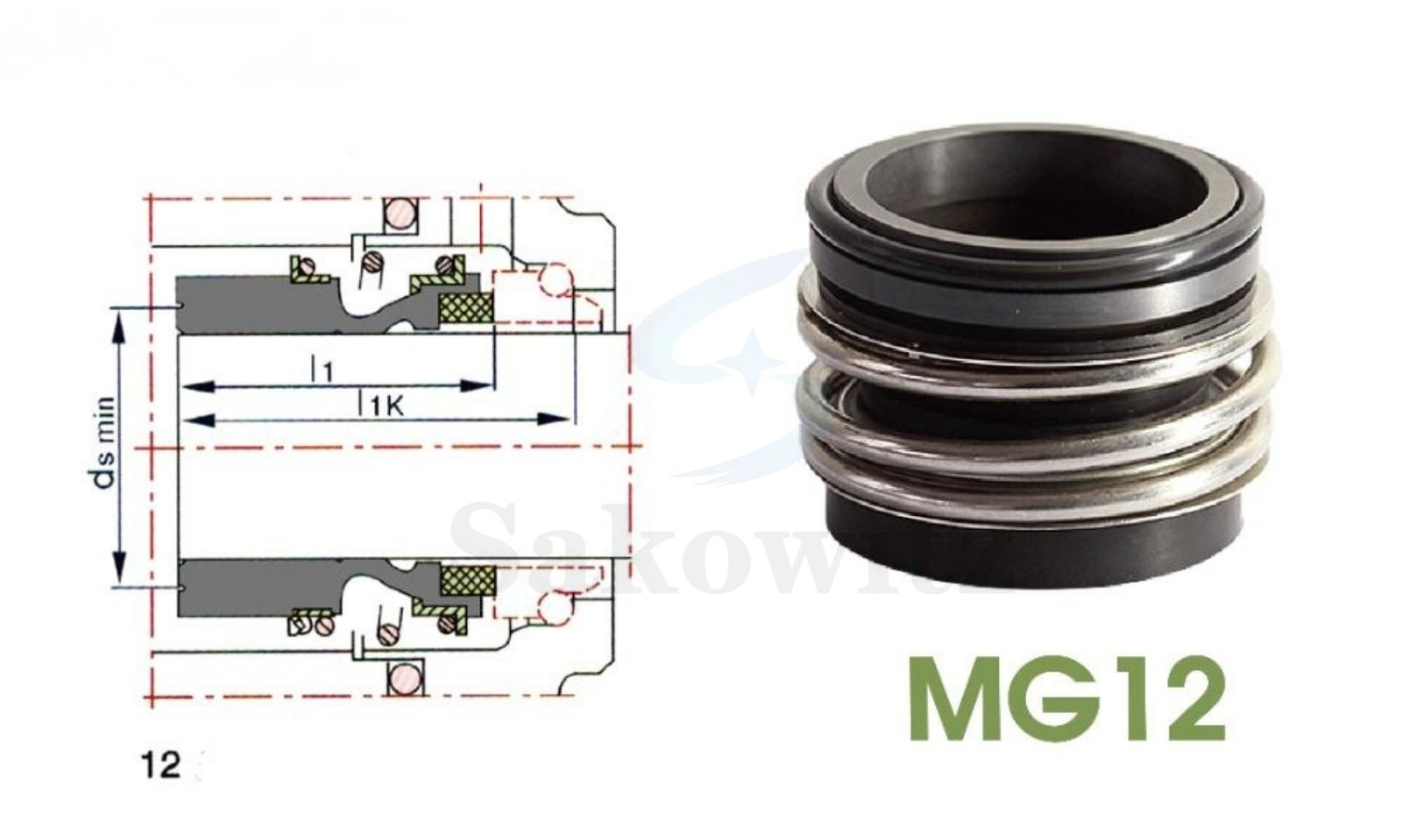

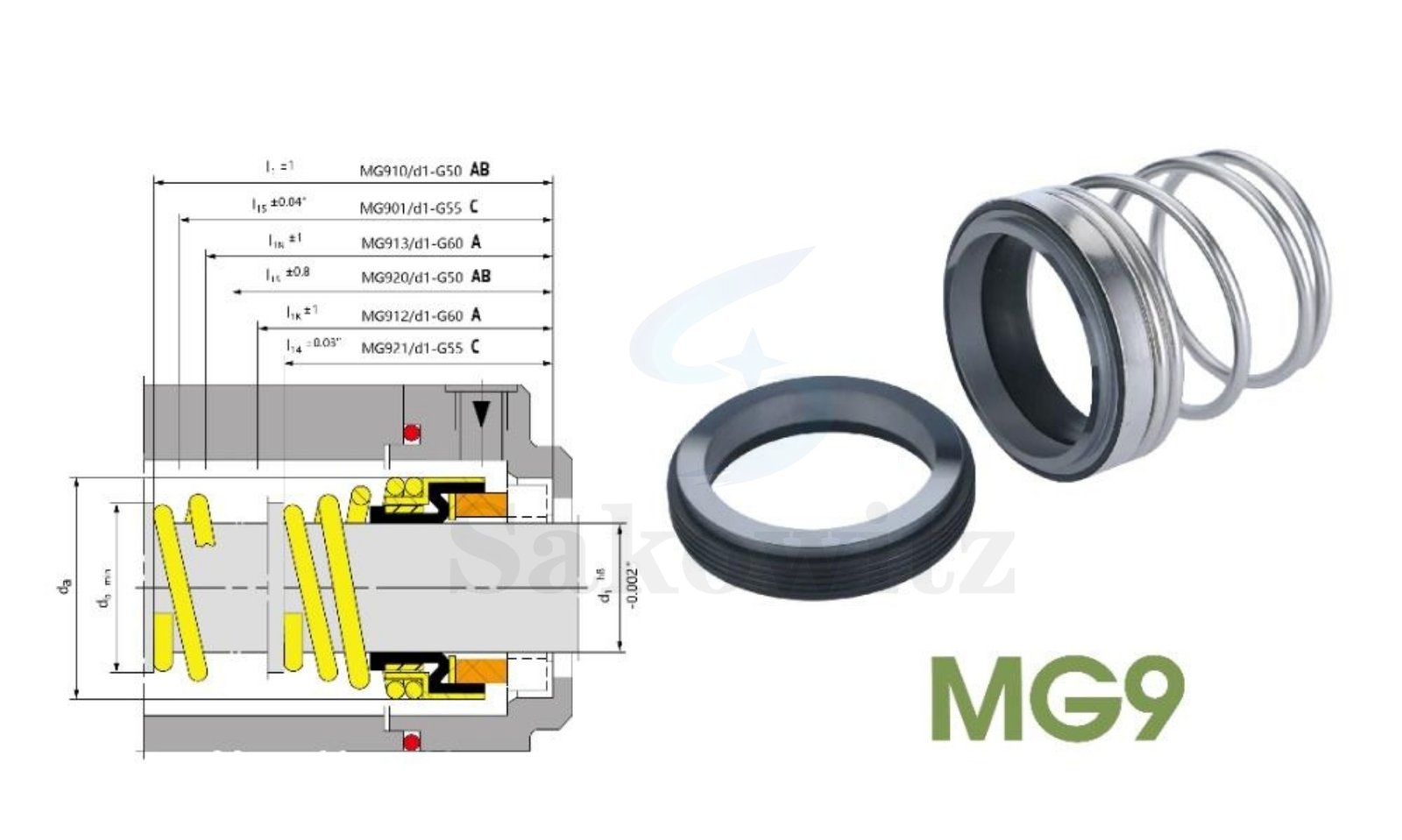

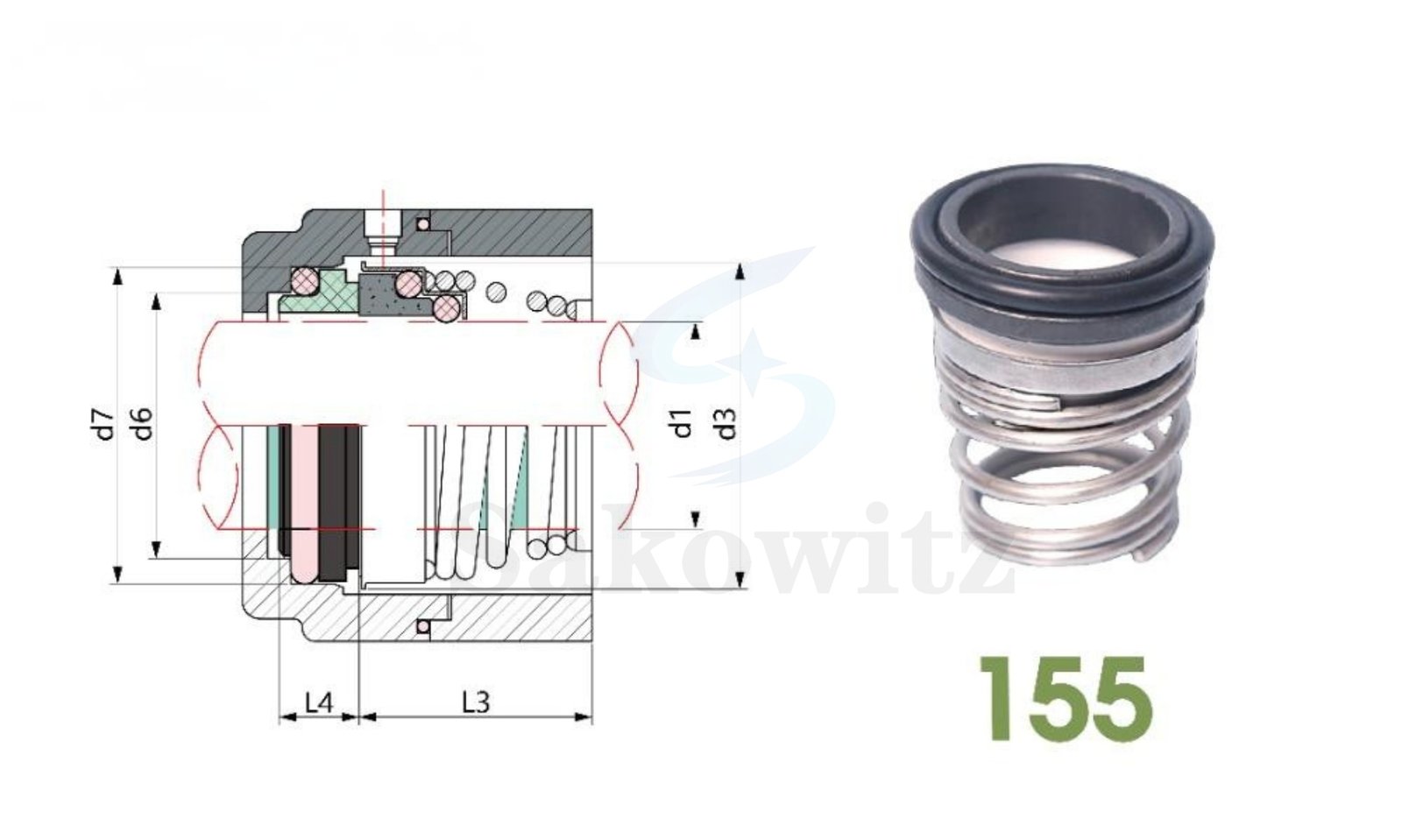

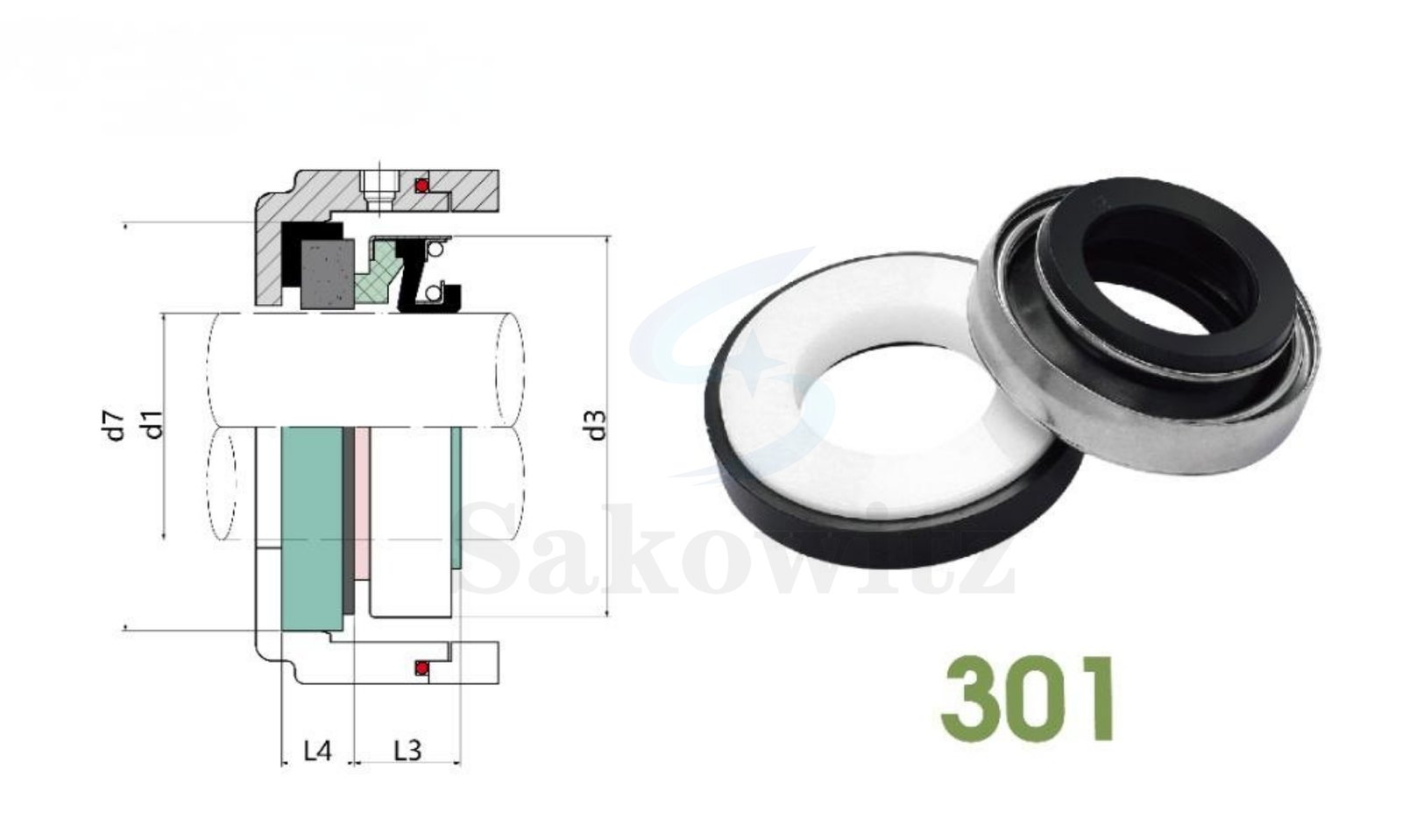

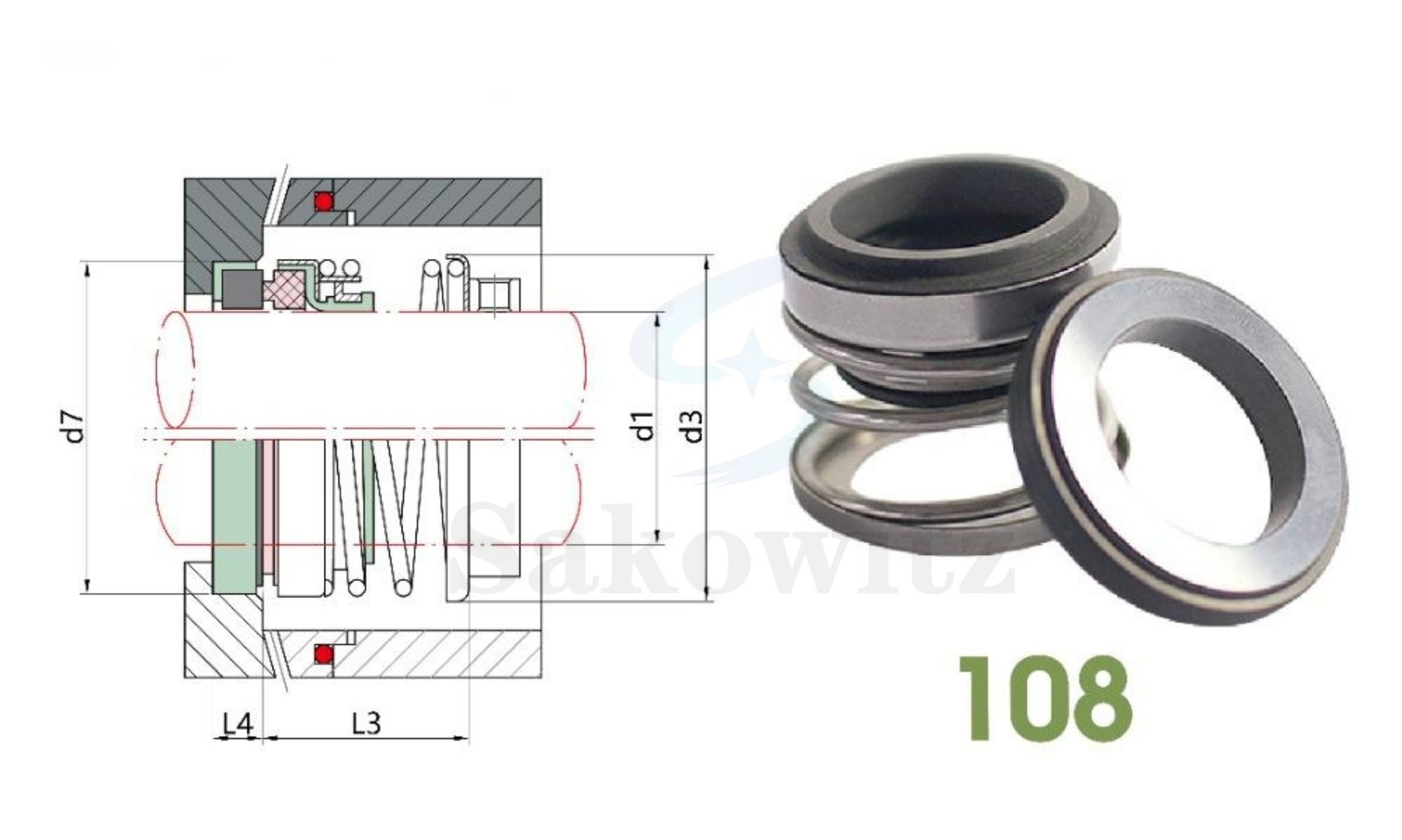

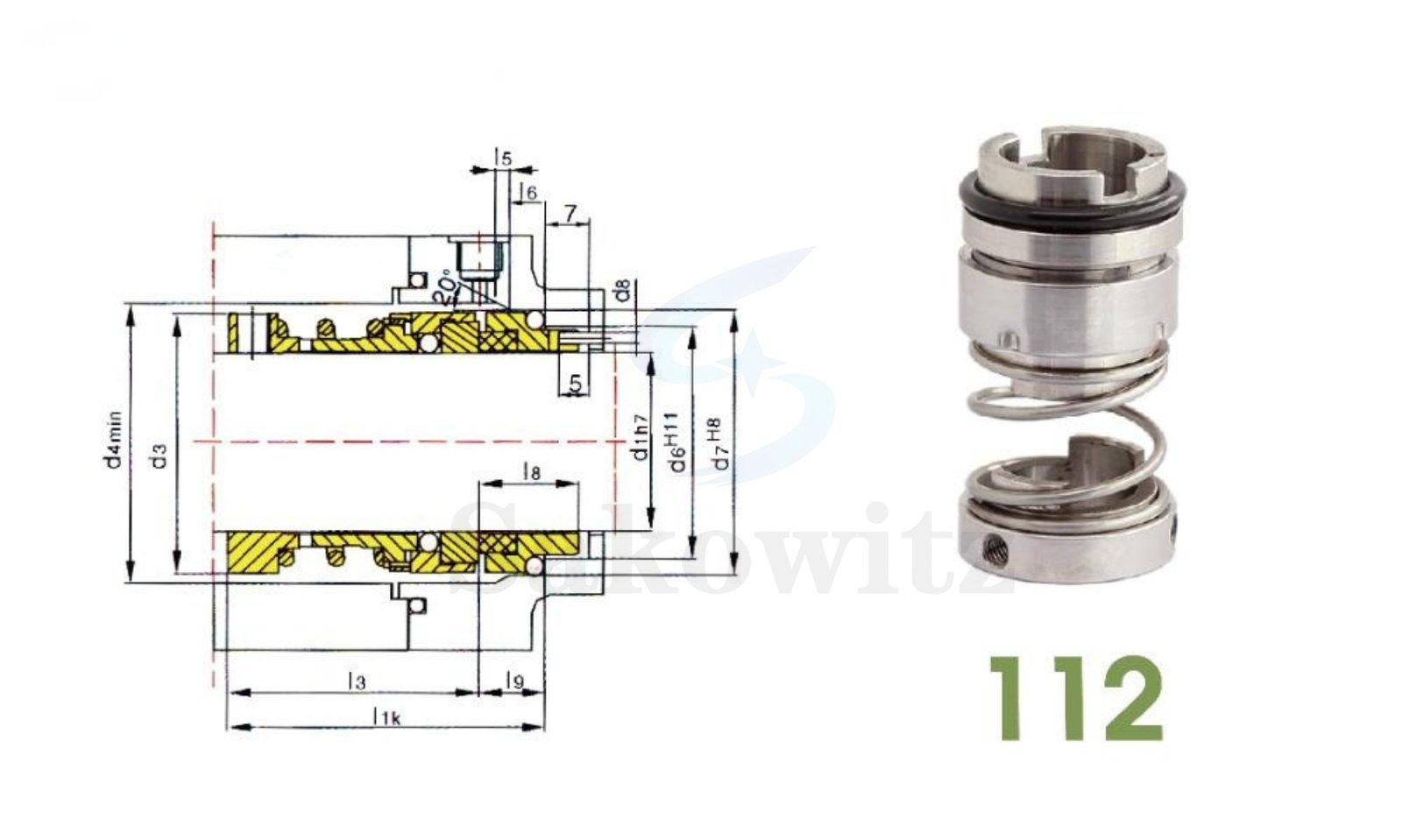

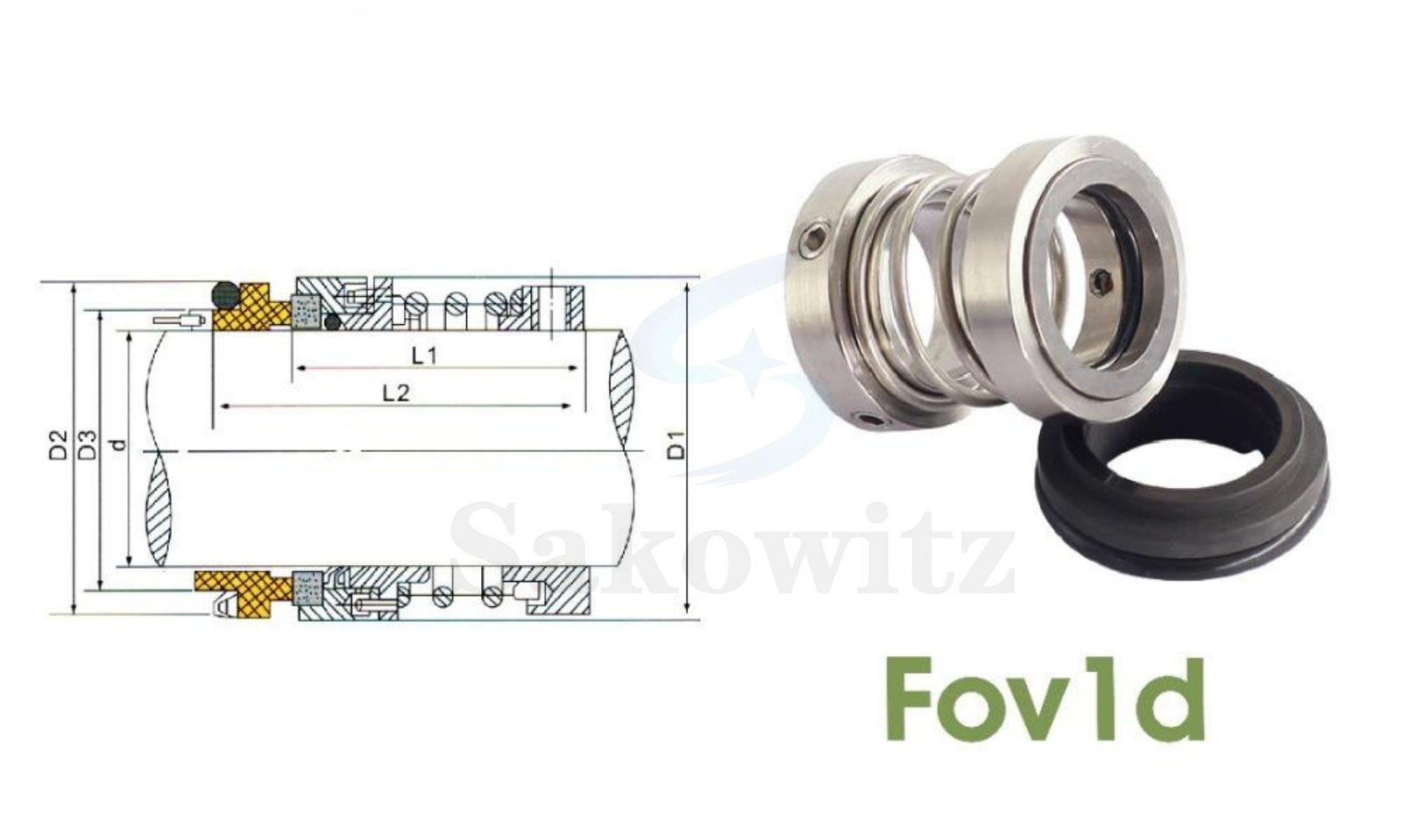

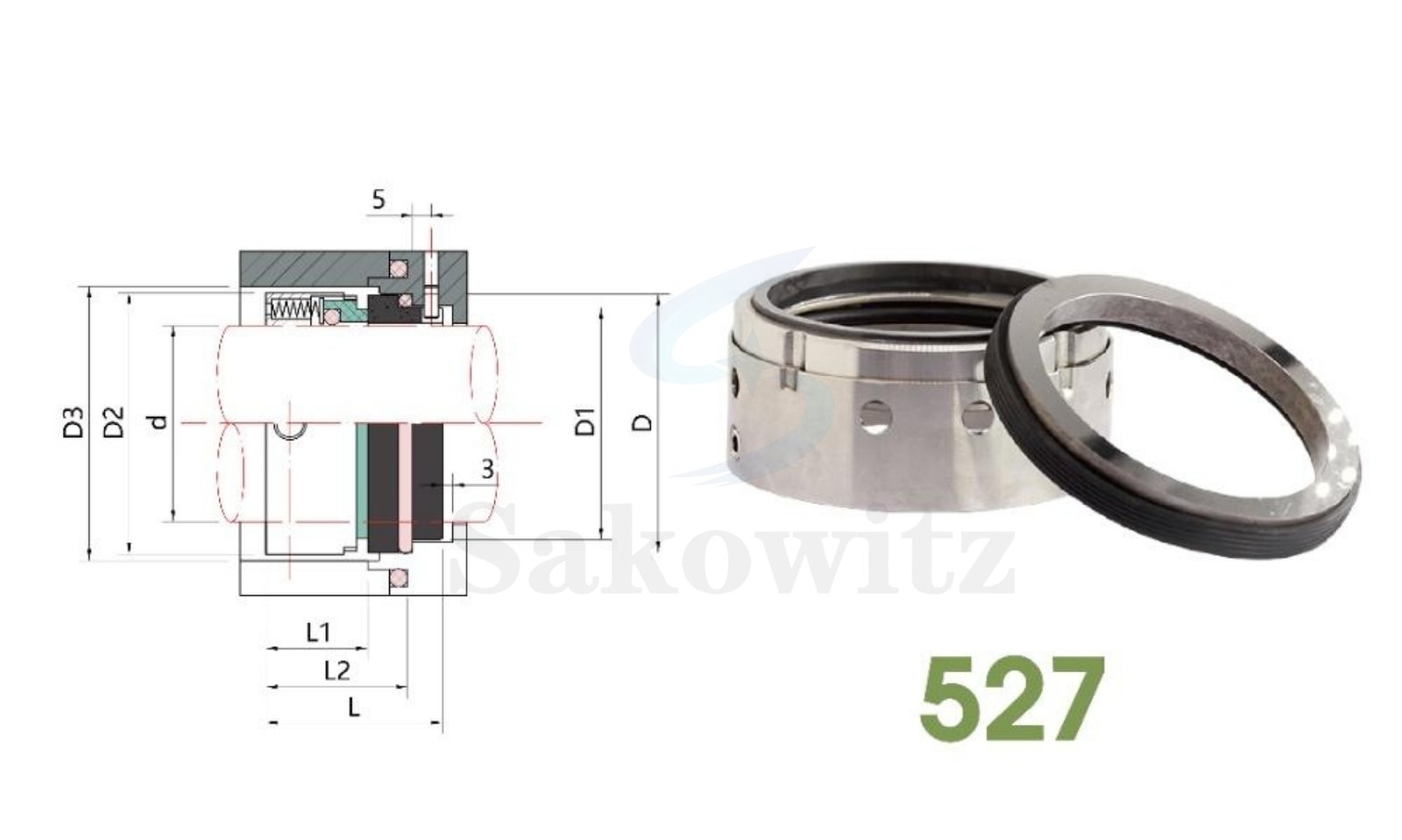

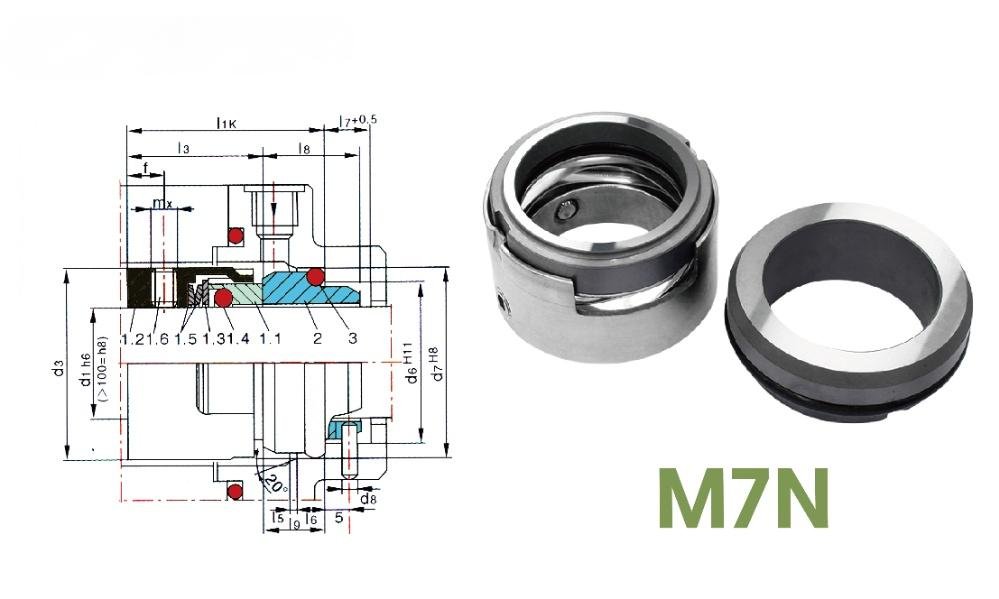

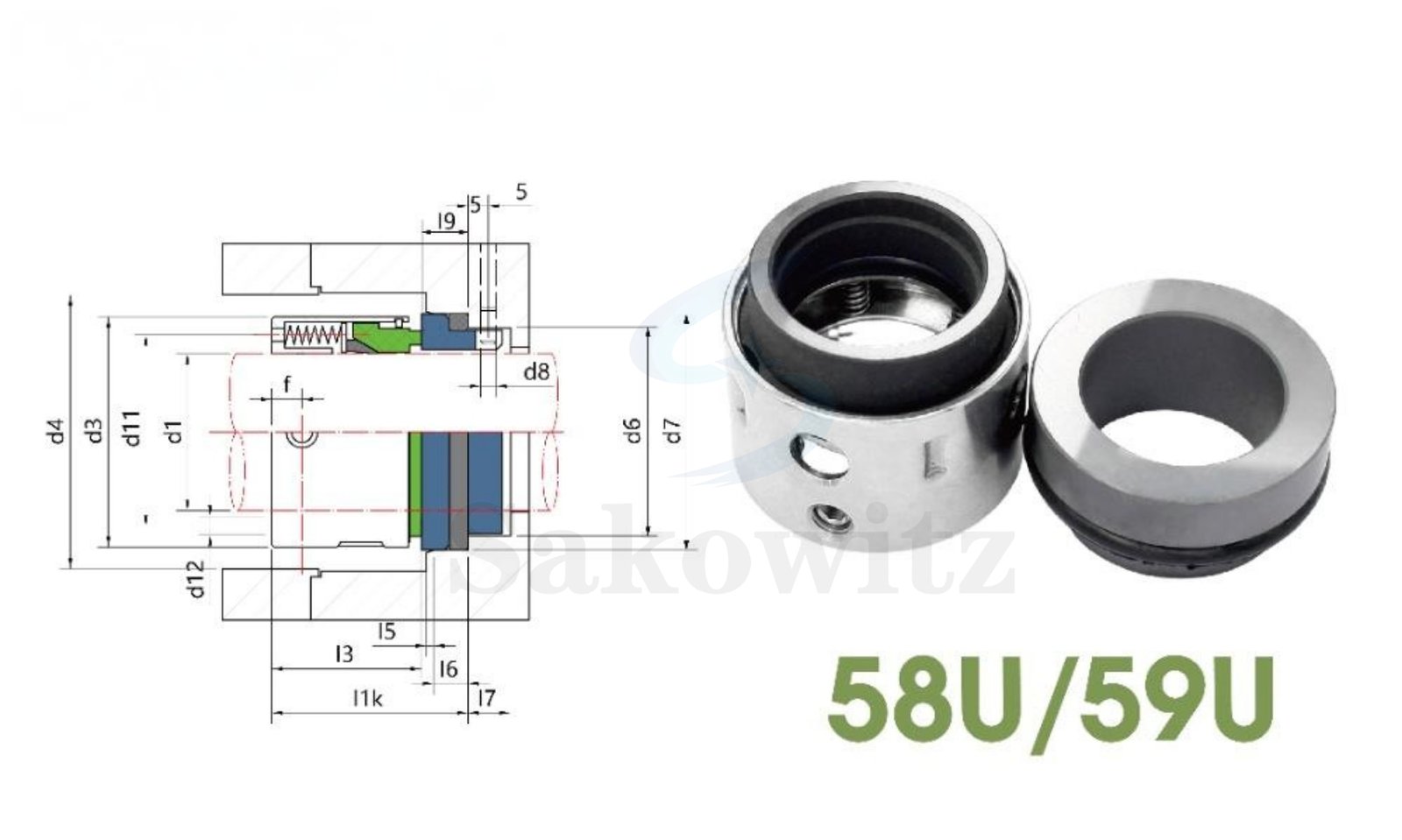

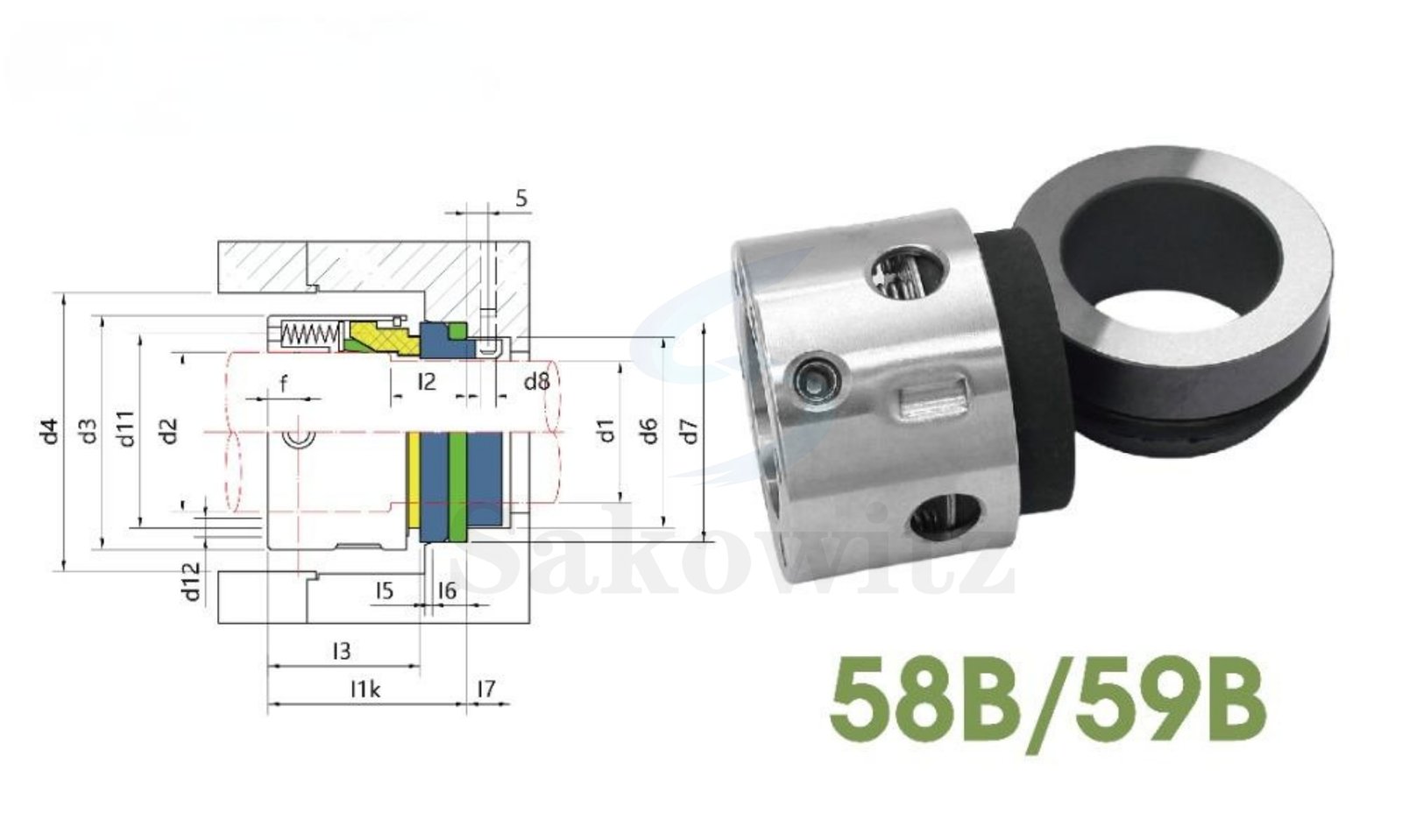

Water Pump Mechanical Seal Product Series

Contact Our Mechanical Seal Specialists for Questions

Contact us, and our professional Sakowit team can help you find the most suitable mechanical seal to enhance the safety of your project.

Why Global Engineers Trust Sakowitz Water Pump Mechanical Seals

Sakowitz has over 30 years of experience in the design and manufacturing of sealing systems and is one of the leading suppliers of pump mechanical seals worldwide.

Proven Engineering Experience

Sakowitz has been dedicated to mechanical sealing technology for over thirty years, and has accumulated rich design and application experience in pumps, compressors and fluid control systems. Our products have been globally verified and have stable performance, which is reliable.

Global Operation and Recognition

Our mechanical seals have been put into use in more than 50 countries and in over 20,000 systems. The products comply with international standards such as ISO 21049 / CE / RoHS, and have demonstrated outstanding durability and consistency in industries such as petrochemicals, water supply, and energy.

Precision CNC Manufacturing

All sealing components are precisely processed by CNC. The flatness of the sealing end face is controlled at <2 μm to ensure zero leakage operation. A strict quality inspection process guarantees the consistency and traceability of the product.

OEM Compatibility & Custom Solutions

Sakowitz offers a variety of OEM-compatible sealing models, and supports customized design based on working conditions, pressure, and medium. Our engineering team can respond promptly and assist customers in optimizing the performance of the pump system.

Material Excellence & Durability

Using high-quality materials such as SiC / Tungsten Carbide / FKM / SS316, it features excellent wear resistance and corrosion resistance. This ensures that the seal can still operate efficiently even in extreme environments.

Reliable Global Support

Sakowitz has a technical and service network in Europe, Asia and the Middle East. We offer fast delivery, installation guidance and maintenance support, helping customers maximize equipment availability and reduce downtime.

Technical Data and Performance Parameters of Water Pump Mechanical Seals

Sakowitz pump mechanical seal has been meticulously designed to maintain stable sealing performance under high pressure, high speed and multi-media working conditions. Its structural materials and manufacturing standards comply with international certification requirements (ISO 21049 / CE / RoHS), ensuring the long-term and reliable operation of the product in various pump systems.

| Parameter | Range / Specification |

|---|---|

| Pressure | ≤ 2.5 MPa |

| Temperature | -20°C ~ +180°C |

| Speed | ≤ 25 m/s |

| Face Materials | Carbon / Silicon Carbide (SiC) / Tungsten Carbide (TC) |

| Elastomers | NBR / FKM / EPDM / PTFE |

| Metals | Stainless Steel SS304 / SS316 |

| Applicable Media | Water, Oil, Weak Acid / Alkali |

| Standards Compliance | ISO 21049 / CE / RoHS |

Industrial Applications of Sakowitz Water Pump Mechanical Seals

Sakowitz mechanical seals for pumps are widely employed across numerous critical industries worldwide due to their stable performance and exceptional durability. They provide safe and reliable sealing solutions for diverse sectors, effectively reducing leakage, lowering energy consumption and extending equipment service life.

Sakowitz seals ensure leak-free operation of clean and wastewater pump systems during continuous service. Their corrosion-resistant design accommodates water containing impurities, extending pump service life and reducing maintenance costs.

It is applied to cooling water, chemical media and process fluid systems. The high-wear-resistant sealing surface (SiC/TC) can withstand high pressure and high temperature operation, ensuring long-term stability.

Suitable for continuous operation of agricultural pumps and sprinkler irrigation equipment. Sakowitz seals can withstand pressure fluctuations and media containing mud and water, maintaining long-term sealing performance.

Widely employed in circulating water pumps and cooling systems. Featuring a compact design and straightforward installation, it minimises operational vibration and leakage risks.

Chemical-resistant materials (such as FKM, PTFE) ensure the stability of the seal in acidic, alkaline and solvent environments. It is applicable to chemical pumps, reaction vessels and conveying systems to prevent leakage and avoid safety risks.

Used for seawater circulation pumps, cooling systems and auxiliary equipment of power stations. SS316 / Duplex metal components are adopted to prevent salt spray corrosion and enhance reliability.

Frequently Asked Questions About Sakowitz Water Pump Mechanical Seals

Q1: Can Sakowitz seals replace OEM brands like Grundfos or KSB?

Sure. Sakowitz offers OEM equivalent models and customized engineering solutions, which can directly replace mechanical seals of mainstream brands. We can also precisely match and optimize the design based on the pump model, shaft diameter and operating conditions.

Q2: What’s the typical lifespan of a water pump mechanical seal?

The general service life is 2 to 5 years, depending on the type of medium, operating temperature, pressure and maintenance conditions. The correct installation and cooling system can extend the service life of the seal by more than 50%.

Q3: Do you supply double seals for submersible or high-pressure pumps?

Yes. Sakowitz can supply Double Mechanical Seal structures, suitable for submersible pumps, oil-cooled pumps and high-pressure systems, ensuring complete sealing under extreme conditions.

Q4: Are Sakowitz seals suitable for hot or corrosive water applications?

Yes. Our seals are made of corrosion-resistant and high-temperature resistant materials such as silicon carbide (SiC) and fluororubber (Viton), ensuring long-term stability in hot water, weak acids and alkalis, and slightly corrosive fluids.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Engineering Excellence – Precision That Performs

Each Sakowit seal is designed, machined, and tested for maximum reliability and long service life — even in the toughest environments.

Proven Performance – Reliable in Every Industry

Trusted by engineers worldwide for consistent performance in chemical, slurry, and high-demand process systems.

Global Support – Fast Response, Trusted Service

Global network and responsive support ensure you get expert help when you need it — wherever you are.