Screw Pump Mechanical Seal Manufacturer

High-performance mechanical seals engineered for screw pumps — ensuring reliability, zero leakage, and extended service life.

Understanding Screw Pump Mechanical Seals

A Screw Pump is a positive displacement pump that conveys liquids by a rotating screw. It can provide continuous and smooth fluid transportation under high-pressure and high-viscosity working conditions. In such an environment, traditional packing seals are prone to leakage, overheating and wear, resulting in reduced efficiency and frequent maintenance. Mechanical seals achieve reliable sealing through high-precision end face contact and fluid film lubrication. The thickness of the liquid film between the end faces is usually only 1 to 3 microns, which can effectively prevent the medium from leaking along the axis and significantly reduce energy loss.

Compared with packing seals, mechanical seals can: Reduce leakage by over 90%.

- Increase system efficiency by approximately 5% to 10%;

- Extend the operating life of the pump by 2 to 3 times.

Why Screw Pumps Need Mechanical Seals

Screw pumps usually operate in high-pressure and high-viscosity environments. Traditional packing seals are prone to leakage, overheating and wear. Mechanical seals can achieve higher sealing performance and longer service life through precise end face control and liquid film lubrication.

- Withstand high pressure (up to 25 bar) : The balanced structure maintains a stable fit.

- Prevent leakage and wear: The liquid film thickness is only about 2-3 microns, protecting the shaft and end face.

- Enhance efficiency and reduce energy consumption: Less friction, saving 5-8% of energy.

- High temperature resistance and corrosion resistance: Can withstand 250°C and is compatible with various chemical media.

- Extended service life: The operating cycle is increased by 2 to 3 times, reducing maintenance downtime.

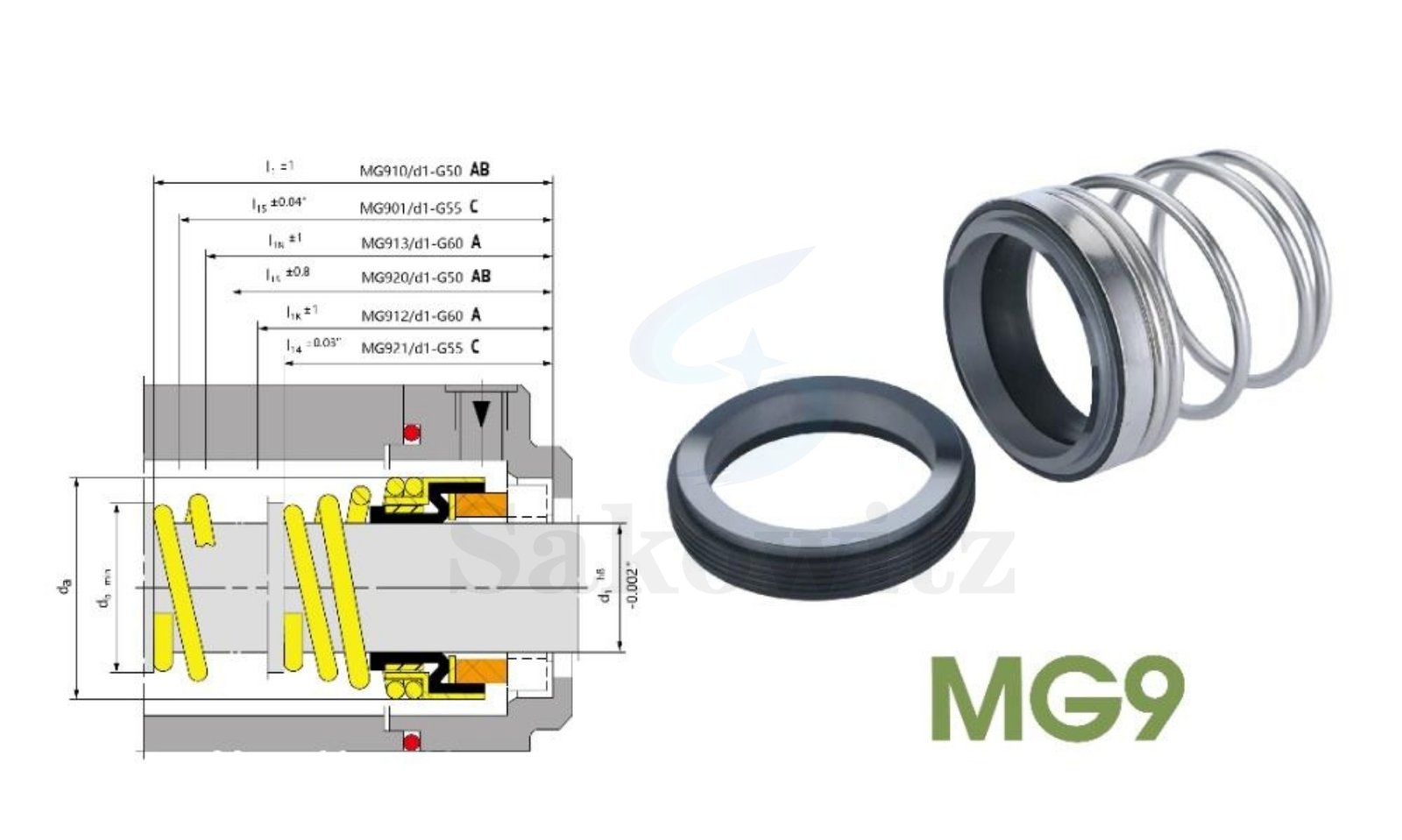

Sakowitz Screw Pump Mechanical Seals

All Sakowitz screw pump seals are modular, API 682-compliant, and 100% factory-tested.

Contact Our Mechanical Seal Specialists for Questions

Contact us, and our professional Sakowit team can help you find the most suitable mechanical seal to enhance the safety of your project.

Key Technical Specifications of Screw Pump Mechanical Seals

| Parameter | Specification / Description | Engineering Insight |

|---|---|---|

| Shaft Diameter | 25 – 150 mm (custom sizes available) | Covers a wide range of industrial screw pump sizes |

| Pressure Rating | Up to 25 bar (363 psi) | Suitable for high-pressure transfer and lubrication systems |

| Operating Temperature | -20°C to +250°C | Handles thermal oils, resins, and chemical fluids |

| Rotational Speed | Up to 20 m/s | Designed for medium to high-speed screw pump shafts |

| Seal Face Materials | Silicon Carbide (SiC), Tungsten Carbide (WC), Carbon | Hard, wear-resistant materials ensure long seal life |

| Secondary Seals (Elastomers) | FKM (Viton®), EPDM, PTFE, FFKM (Kalrez®) | Excellent chemical and temperature resistance |

| Metal Components | 316 Stainless Steel, Duplex Stainless, Hastelloy® | High strength and corrosion resistance |

| Design Type | Single, Double, Cartridge, or Bellows | Flexible configurations for various pump designs |

| Applicable Standards | API 682 / ISO 21049 / FDA / ATEX | Certified for global industrial compliance |

| Service Life Expectation | 2–5 years (depending on medium and operation) | Proven reliability under demanding conditions |

Industries and Applications of Screw Pump Mechanical Seals

Sakowit mechanical seals are designed for demanding industrial environments —where high viscosity, temperature, and pressure require precision-engineered sealing performance. All products have been industrially verified to ensure zero leakage and long service life during continuous operation.

For lubricating oil transfer pumps and fuel transfer pumps. Mechanical seals prevent oil leakage under high pressure and high temperature conditions, maintaining system safety and cleanliness.

Suitable for conveying corrosive or high-viscosity chemical media. Constructed from chemically resistant materials to ensure long-term stability.

For use with food-grade media such as syrups, vegetable oils, and fats. Complies with FDA/USP Class VI standards to prevent contamination.

For sterile transfer and low-shear fluid systems. Sealing materials are clean and contamination-free, supporting CIP/SIP cleaning.

Suitable for lubricant and fuel transfer and circulation systems. Designed for high-temperature operation, reducing maintenance frequency and enhancing equipment operational efficiency.

Designed for the conveyance of sludge, slurries and high-solids-content fluids. Its wear-resistant construction prevents clogging, making it suitable for heavy-duty continuous operation.

Why Sakowit Is the Preferred Choice

Choosing Sakowit means choosing stable performance, engineering precision and global trust. Our mechanical seals are specially designed for screw pumps, have been strictly tested, and can increase the average lifespan by 2–3 times, and comply with the API 682 / ISO 21049 international standards.

Precision Engineering

Sakowit has over 30 years of experience in mechanical seal design. Every product is modeled, tested and verified by professional engineers. The sealing end faces are ground to a flatness of less than 2 μm, ensuring zero leakage under high pressure.

Material Excellence

All seals are made of high-grade materials such as silicon carbide, tungsten carbide, and Hastelloy®. Tests have shown that their corrosion resistance is over 30% better than that of conventional alloys. This ensures stability in high-pressure, corrosive or hot medium environments.

Global Support & OEM Compatibility

Sakowit seals can be directly replaced for a variety of OEM models (such as Bornemann, Seepex, Leistritz). We offer fast delivery, online selection and remote technical support. Our global customer satisfaction rate exceeds 98%.

Frequently Asked Questions about Screw Pump Mechanical Seal

Q1: Can Sakowitz seals replace my OEM screw pump seal?

Yes. Sakowit offers both direct-fit replacements and custom-engineered seals for most global brands, including Bornemann, Seepex, and Leistritz. We can directly match mainstream brand models, or customize designs based on the pump size and working conditions.

Q2: What’s the typical service life?

Typically 2–5 years, depending on pressure, medium, and temperature. After testing, it has been found that under standard working conditions, its service life is 2 to 3 times longer than that of traditional packing seals.

Q3: Do you supply API Plan support systems?

Yes. We support API Plan 11, 32, 52, and 53 for effective cooling and lubrication. Sakowit offers complete Seal Support Systems to ensure long-term stable operation.

Q4: Are your seals suitable for food-grade or hygienic use?

Yes. We use FDA- and USP Class VI-approved materials such as PTFE, FKM, and EPDM. It is applicable to industries such as food, beverages, and pharmaceuticals that have strict requirements for cleanliness.

Q5: Can I get technical guidance before ordering?

Absolutely. Our engineers offer free pre-selection advice based on pump type, fluid, and operation data. Sakowitz offers free technical assessment and selection advice to help customers obtain the best matching sealing solution.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Engineering Excellence – Precision That Performs

Each Sakowit seal is designed, machined, and tested for maximum reliability and long service life — even in the toughest environments.

Proven Performance – Reliable in Every Industry

Trusted by engineers worldwide for consistent performance in chemical, slurry, and high-demand process systems.

Global Support – Fast Response, Trusted Service

Global network and responsive support ensure you get expert help when you need it — wherever you are.