Marine Mechanical Seal Manufacturer

– Provide high-reliability sealing solutions for ships, Marine engineering and offshore platforms.

Adopting corrosion-resistant alloys and high-performance sealing materials, it ensures long-term stable sealing and zero leakage operation in high-salt, high-pressure and continuous operation environments.

What Is a Marine Mechanical Seal

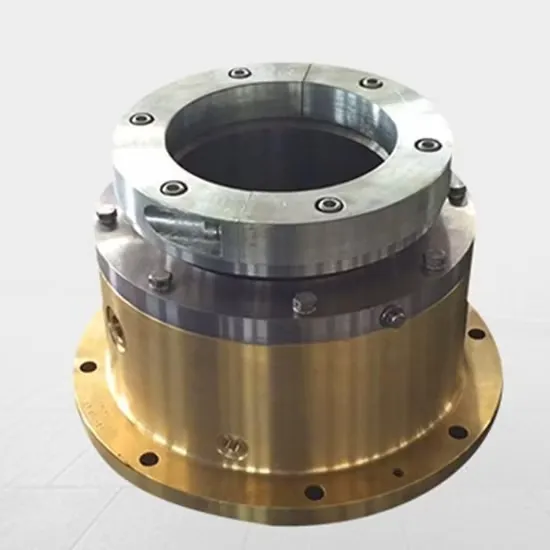

Marine Mechanical Seal is a high-performance sealing component specifically designed for marine vessels, offshore engineering and platform equipment, used to prevent the leakage of seawater, lubricating oil or coolant along the pump shaft. It forms a sealing interface through the smooth friction pair surface between the rotating ring and the stationary ring, maintaining a stable and continuous sealing effect during rotation.

This type of seal typically employs corrosion-resistant metal materials (such as Duplex, Hastelloy®, SS316), saltwater-resistant elastomers (FKM, EPDM), and silicon carbide or tungsten carbide friction pairs, which can withstand the effects of salt spray, chemical corrosion, and high-pressure environments for a long time. Compared with traditional packing seals, the Marine Mechanical Seal has a longer service life, higher sealing reliability, and lower maintenance requirements.

Advantages of Marine Mechanical Seals in Ship Systems

In marine equipment, Marine Mechanical Seal is a crucial component that ensures the stable operation of pumps and power systems. It effectively prevents seawater, lubricating oil, or coolant from leaking along the shaft, thereby avoiding corrosion of the engine room and energy loss. Compared to traditional packing seals, mechanical seals can significantly enhance system efficiency and safety.

Mechanical seals can maintain stable operation under high pressure, high temperature and strong vibration conditions, and are suitable for various marine pumps and propulsion systems. They can also reduce the frequency of maintenance, lower operating costs, and extend the service life of bearings and pump bodies. Studies have shown that compared with packing seals, seawater pumps using mechanical seals can reduce leakage losses by more than 90% and significantly improve the energy utilization efficiency of ships.

Marine Mechanical Seal Product Series

Свяжитесь с нашими специалистами по механическим уплотнениям, чтобы задать вопросы

Свяжитесь с нами, и наша профессиональная команда Sakowit поможет вам подобрать наиболее подходящее механическое уплотнение для повышения безопасности вашего проекта.

Sakowitz Engineering – Marine Mechanical Seal Design Expertise

Sakowitz specializes in the research and manufacturing of Marine Mechanical Seals, providing high-performance sealing solutions for ships and marine engineering equipment. Our products maintain excellent stability in high-salt, high-pressure, and high-vibration environments, ensuring that the equipment operates without leakage for an extended period.

- Diverse structural types: Offers single-ended, double-ended, balanced and unbalanced designs, suitable for different fluids and pressure levels.

- High-quality material combination: Uses SiC / WC / Carbon friction pairs combined with FKM / PTFE / EPDM elastomers, balancing wear resistance and seawater resistance.

- Upgrade of metal components: Selects SS316, Duplex, Hastelloy®, Titanium and other high-grade metals to prevent salt fog corrosion and fatigue cracking.

- Wide range of equipment compatibility: Applicable to cooling pumps, ballast pumps, fire pumps, seawater circulation pumps and propulsion systems.

- Compliant with international standards: The product has passed API 682, ISO 21049, ABS, CE and other certifications, meeting the norms of the global shipping and marine industries.

Technical Performance of Sakowitz Marine Mechanical Seals

Sakowitz Marine Mechanical Seals are specifically engineered for marine environments, maintaining consistent sealing performance under conditions of high salinity, humidity, and vibration. All components are manufactured from corrosion-resistant and wear-resistant materials, ensuring stable and reliable operation throughout extended service life.

| Параметр | Спецификация / диапазон | Описание |

|---|---|---|

| Давление | ≤ 30 bar | Suitable for medium to high-pressure marine pump systems. |

| Температура | -20°C ~ +200°C | Operates reliably under both cold and hot fluid conditions, including steam. |

| Скорость | ≤ 25 m/s | Designed for high-speed pumps and propulsion systems. |

| Материалы для лица | SiC / WC / Carbon | Provides high wear resistance and low friction for extended lifespan. |

| Эластомеры | FKM / EPDM / PTFE | Excellent seawater and chemical resistance for marine applications. |

| Металлические компоненты | SS316 / Duplex / Titanium | Corrosion-resistant alloys ensure structural integrity in harsh environments. |

| Стандарты | API 682 / ISO 21049 / ABS / CE | Compliant with international marine and safety certifications. |

| Приложения | Seawater Pumps, Cooling Systems, Fire Pumps, Ballast Pumps | Engineered for reliable sealing performance across critical marine systems. |

Global Marine Applications of Sakowitz Mechanical Seals

Sakowitz’s Marine Mechanical Seal is widely used in the global shipbuilding and marine engineering industries. The product boasts excellent corrosion resistance and sealing stability, capable of withstanding harsh conditions such as salt fog, high pressure, and high humidity, ensuring the safe and efficient operation of critical equipment.

Used for seawater pumps, cooling pumps and ballast systems to prevent seawater leakage and extend pump lifespan.

Suitable for oil and gas extraction equipment, providing stable sealing to prevent fluid leakage and system contamination.

Used in submarines and propulsion pump systems to ensure safety and sealing performance in high-pressure underwater environments.

Provide anti-corrosion sealing in seawater circulation and seawater desalination equipment.

Support long-term navigation operations, reduce maintenance frequency, and enhance equipment reliability.

Applied in the power compartments and cooling circuits of ships, it enhances energy efficiency and safety.

Why Choose Sakowitz for Marine Mechanical Seals

Sakowitz specializes in the research and manufacturing of high-performance Marine Mechanical Seals. With over thirty years of industry experience, we provide stable and reliable sealing solutions to global shipbuilding and marine engineering customers. Our products excel in corrosion resistance, pressure resistance, and lifespan, and are widely used in various seawater pumps, propulsion systems, and cooling circulation equipment.

- Rich Experience Accumulation: With over 30 years of experience in mechanical seal design and manufacturing, familiar with ship standards and complex working conditions.

- Global Trustworthy Application: More than 20,000 sets of equipment are operating in marine and port environments in over 50 countries.

- Высокоточное производство: CNC processing accuracy is controlled at <2 µm, ensuring perfect alignment of the end face seals.

- Fast Delivery and Strong Compatibility: Supports replacement of mainstream OEM pump brand models, with short delivery periods and convenient assembly.

- High-Quality Corrosion-Resistant Materials: Uses alloys such as Duplex, Titanium, and Hastelloy®, to withstand salt spray and seawater corrosion.

- Full Process Technical Support: Provides design selection, installation training, and global after-sales service.

FAQ – Common Questions About Cartridge Mechanical Seals

Q1: Can Sakowitz's marine sealing products replace those of brands like John Crane or EagleBurgmann?

Sure. We offer OEM replacement solutions that are compatible with mainstream brands. We can also customize the design according to the customer’s pump type and achieve seamless installation.

Q2: Are these seals suitable for use in seawater or saltwater environments?

Yes. Using high corrosion-resistant metals such as Duplex and Hastelloy®, it provides long-term protection against salt fog and high-salt environments.

Q3: How long is the typical service life in a marine environment?

It can typically operate continuously for 3 to 5 years. The exact lifespan depends on the operating conditions, the purity of the medium, and the maintenance frequency.

Q4: Do you have ABS or API certification?

Yes. All of Sakowitz’s Marine Mechanical Seals comply with international classification standards such as ABS, API 682, and ISO 21049.

Отправить быструю цитату

Почему нам доверяют 1000+ клиентов

Инженерное превосходство - точность, которая работает

Каждое уплотнение Sakowit разработано, обработано и протестировано для обеспечения максимальной надежности и длительного срока службы - даже в самых жестких условиях эксплуатации.

Проверенная производительность - надежность в любой отрасли

Доверяют инженерам по всему миру за стабильную работу в химических, шламовых и высоконагруженных технологических системах.

Глобальная поддержка - быстрое реагирование, надежное обслуживание

Глобальная сеть и оперативная поддержка обеспечивают получение квалифицированной помощи в нужный момент - где бы вы ни находились.