Pump Seal Manufacturer

– Providing reliable sealing solutions for various industrial pumps to prevent liquids or gases from leaking along the pump shaft.

It features high temperature resistance, corrosion resistance and long service life, ensuring the equipment operates stably for a long time and reducing maintenance costs.

What Is a Pump Seal?

A pump seal is a sealing device used to prevent the leakage of medium along the pump shaft. It can protect the bearings and maintain the operational efficiency of the pump.

It relies on the sealing end faces between the rotating ring and the stationary ring to form a liquid film, achieving stable sealing and reducing friction.

The structure of mechanical seals for pumps typically consists of a rotating ring, a stationary ring, springs and auxiliary sealing elements. Compact in design, it can adapt to variations in pressure, temperature and rotational speed.

In modern industrial systems, the pump seal has become the standard sealing method for water pumps, chemical pumps, sewage pumps and centrifugal pumps, and is an important core component to ensure the safe and efficient operation of equipment.

Why Pumps Need Mechanical Seals

During operation, pumps are subject to changes in pressure, temperature and speed. Therefore, mechanical seals must be used to prevent leakage and ensure system stability. Mechanical seals can form stable end faces, reduce wear and adapt to complex working conditions such as high temperatures, high pressures and corrosive liquids. Compared with packing seals, they have a lower maintenance frequency, can significantly reduce downtime costs and extend the overall service life of the equipment.

Research shows that pump systems using mechanical seals can reduce leakage by more than 90%, making production safer and more environmentally friendly. Mechanical seals not only enhance the efficiency of pumps but also ensure the safety of personnel and equipment, making them an indispensable key component in modern industrial pumps.

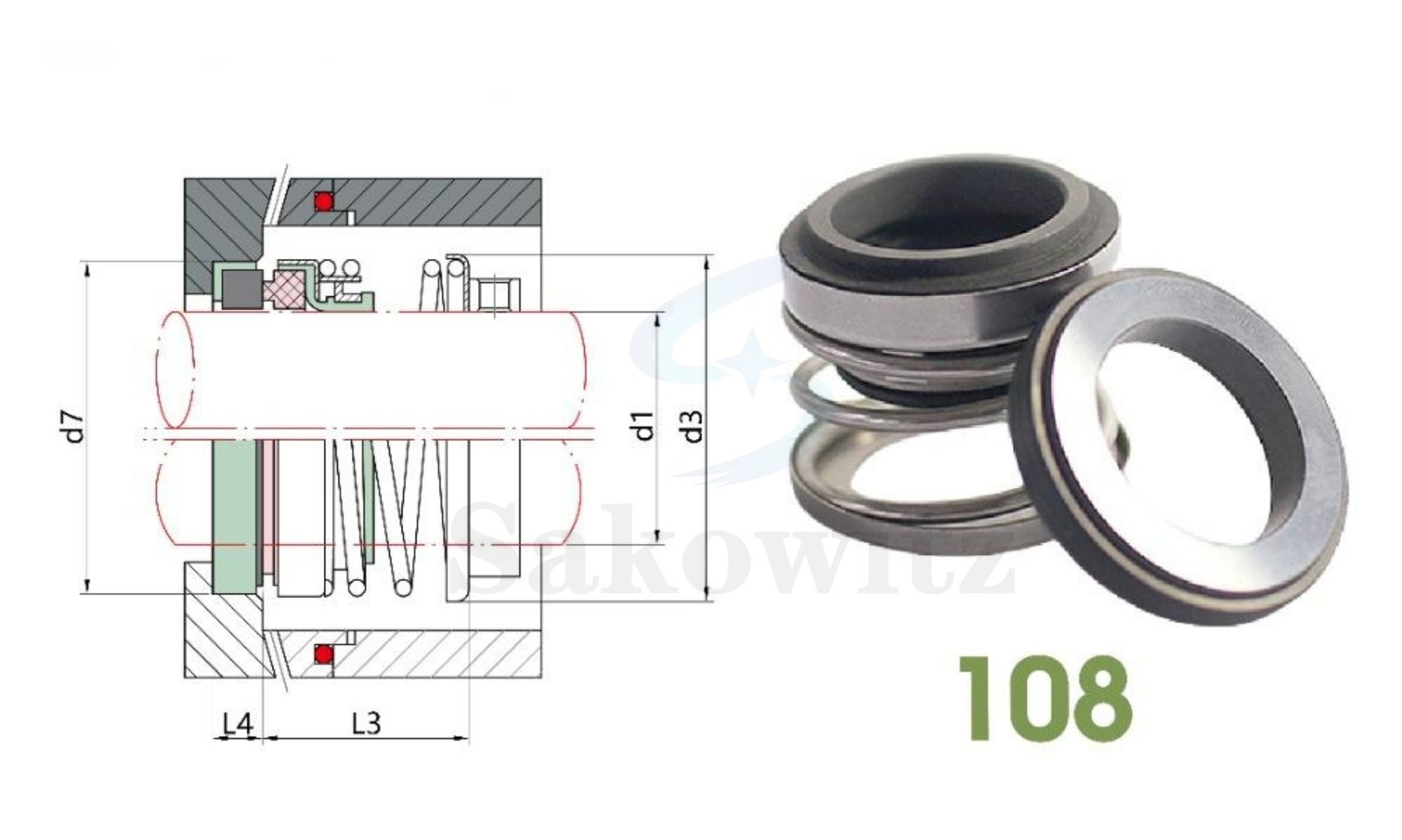

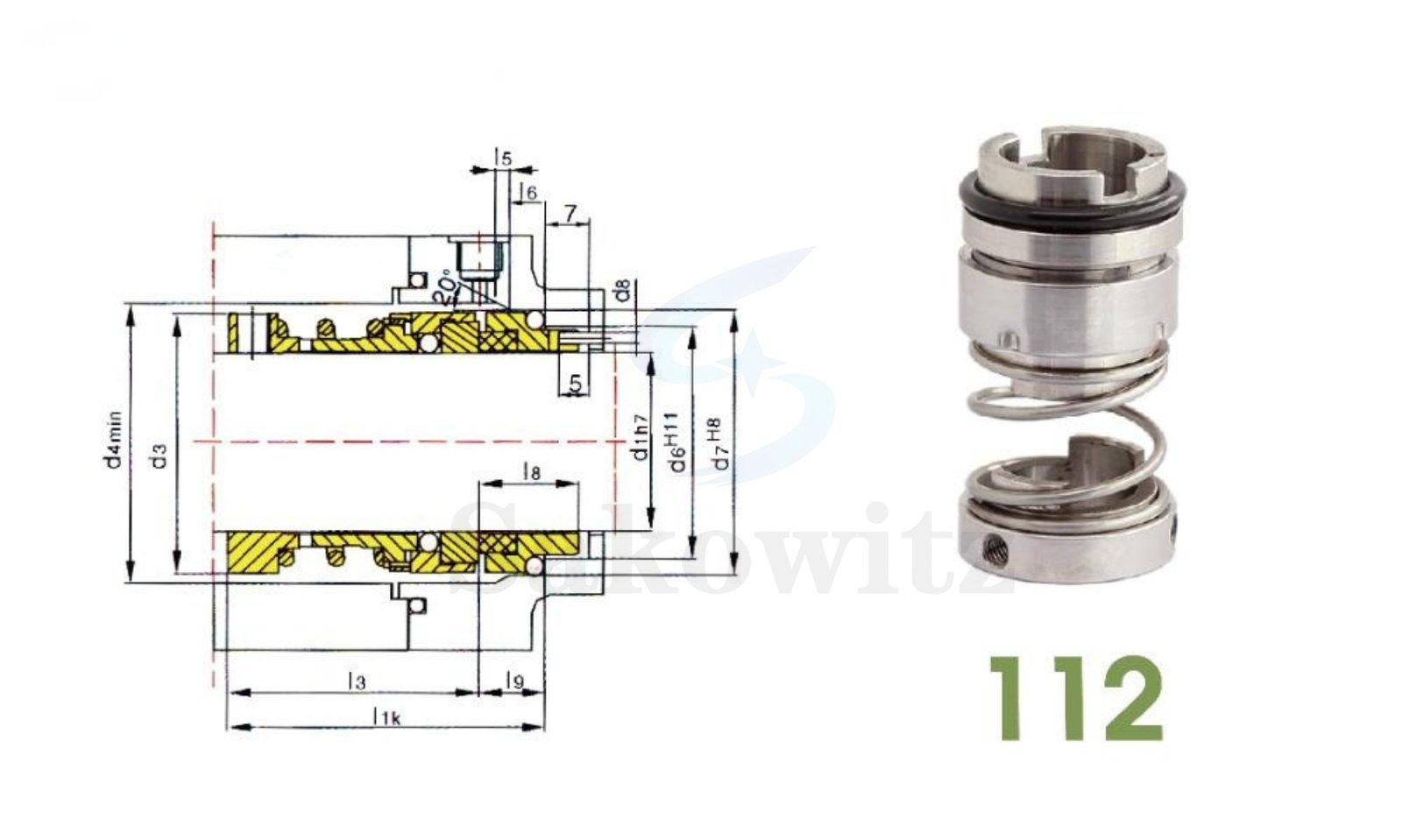

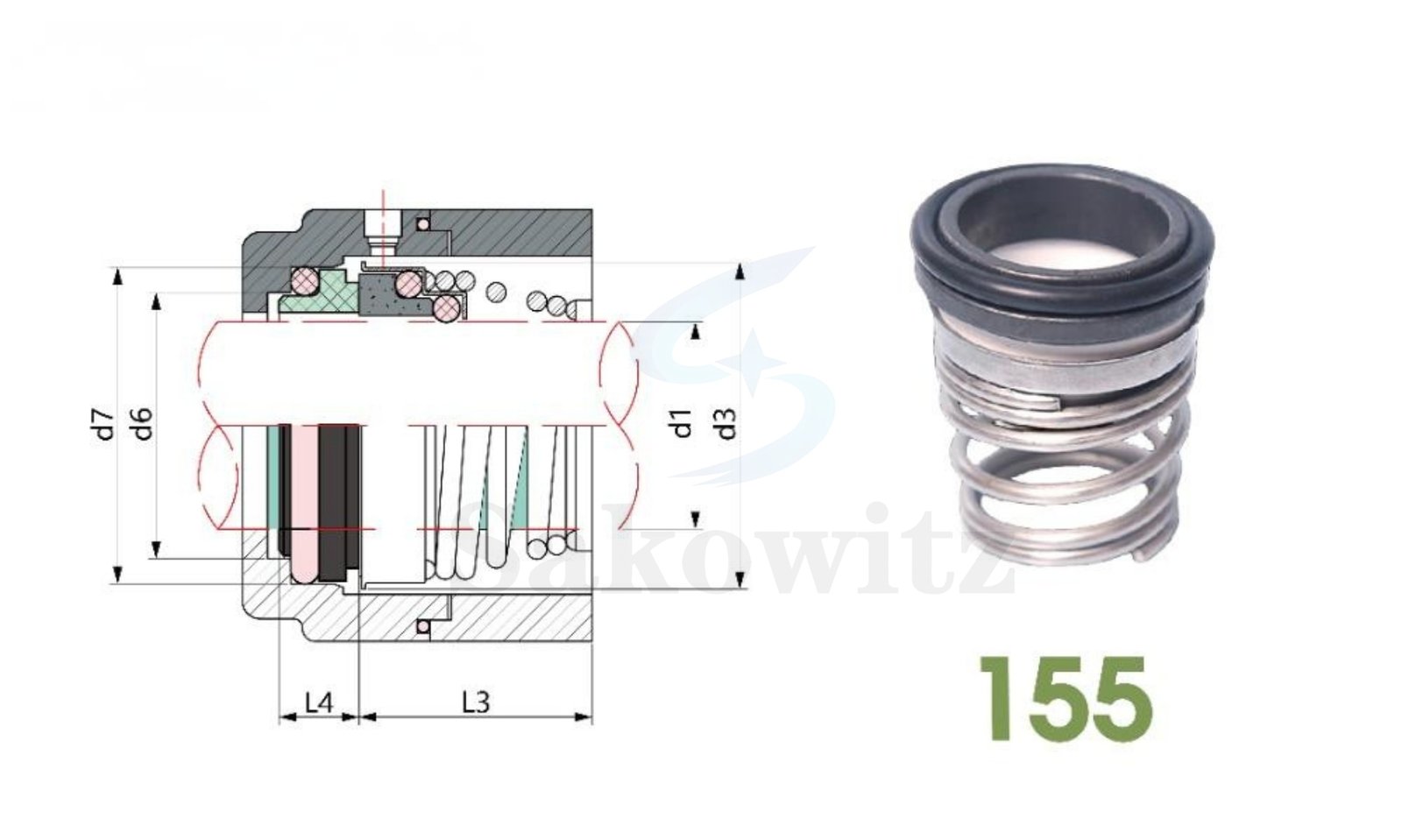

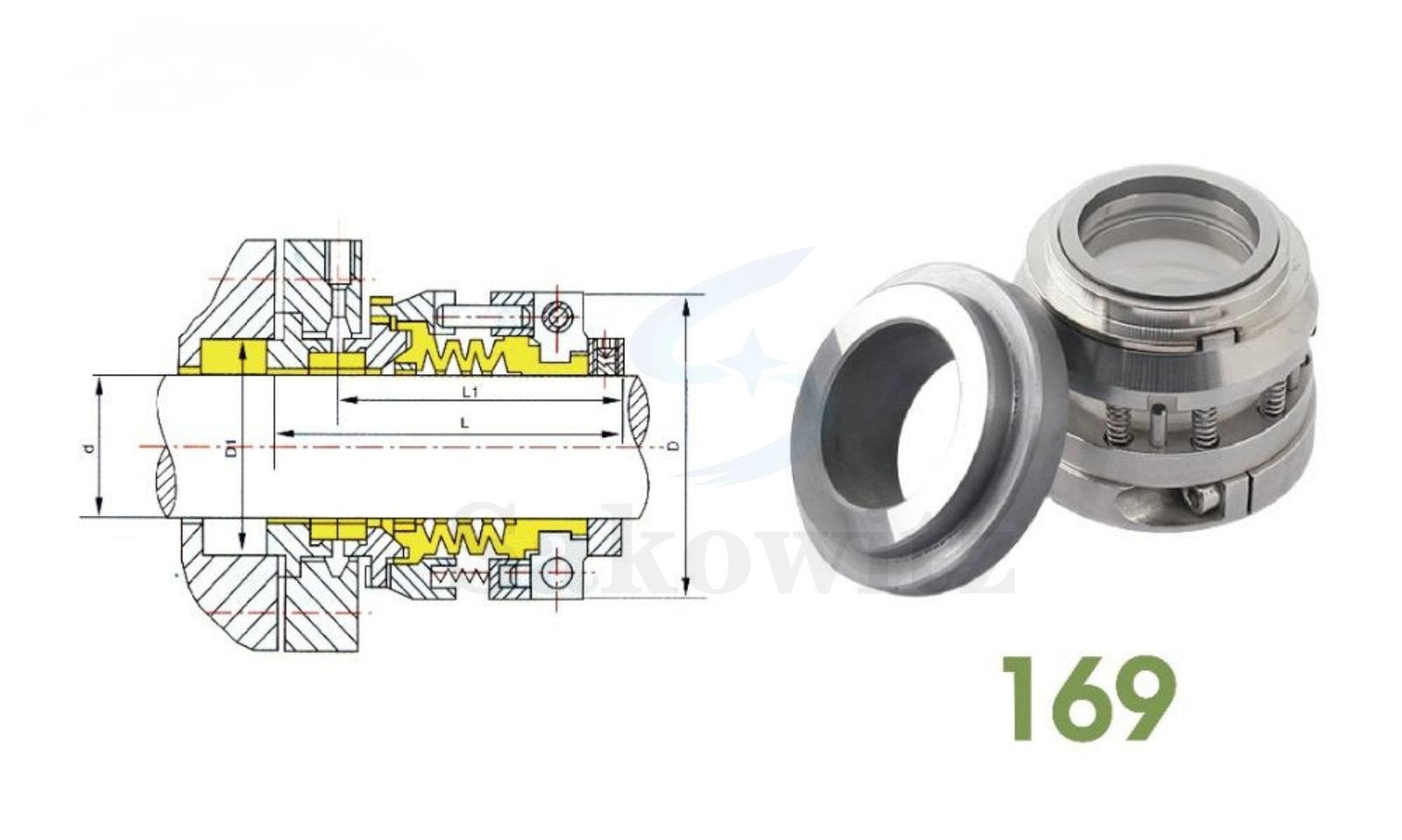

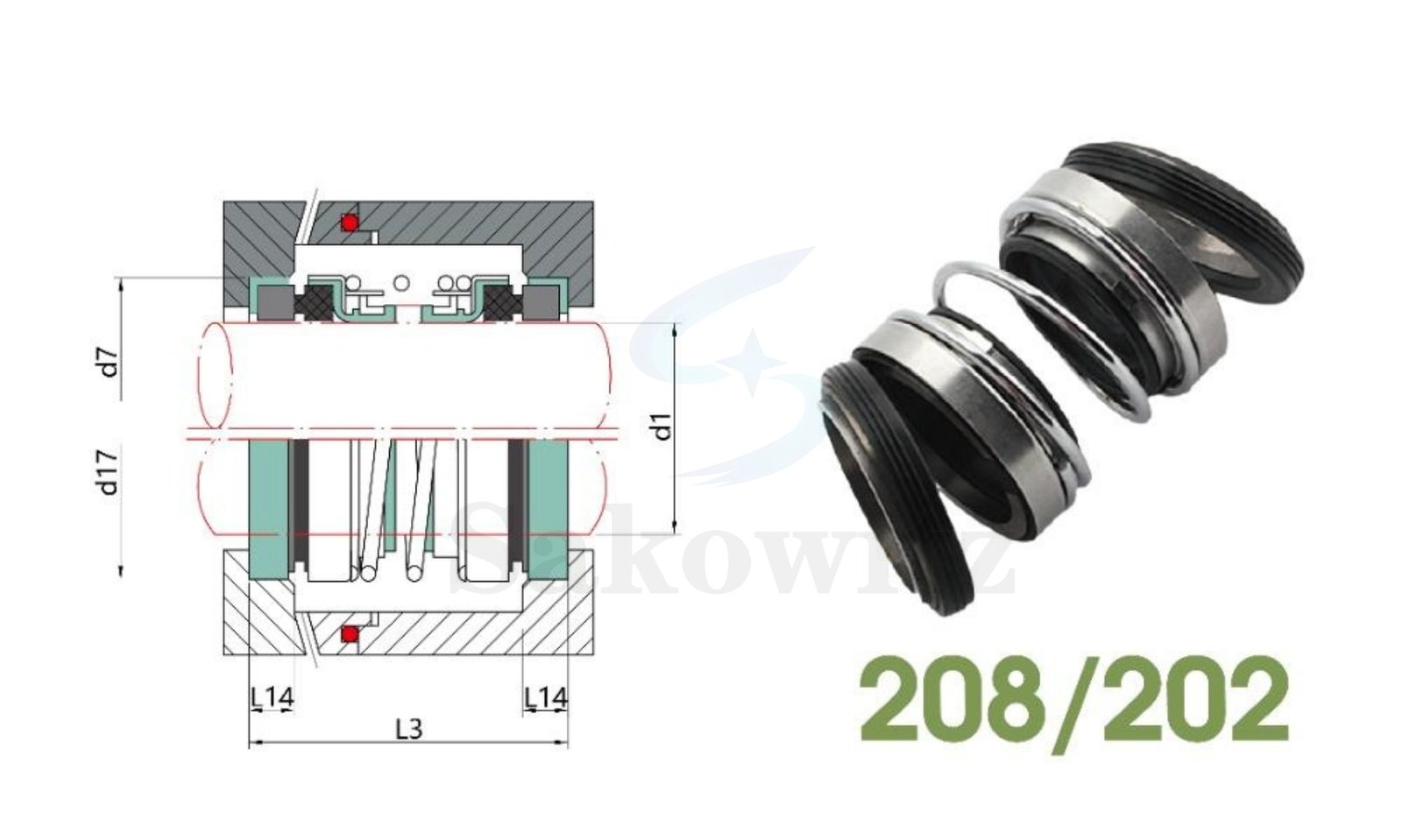

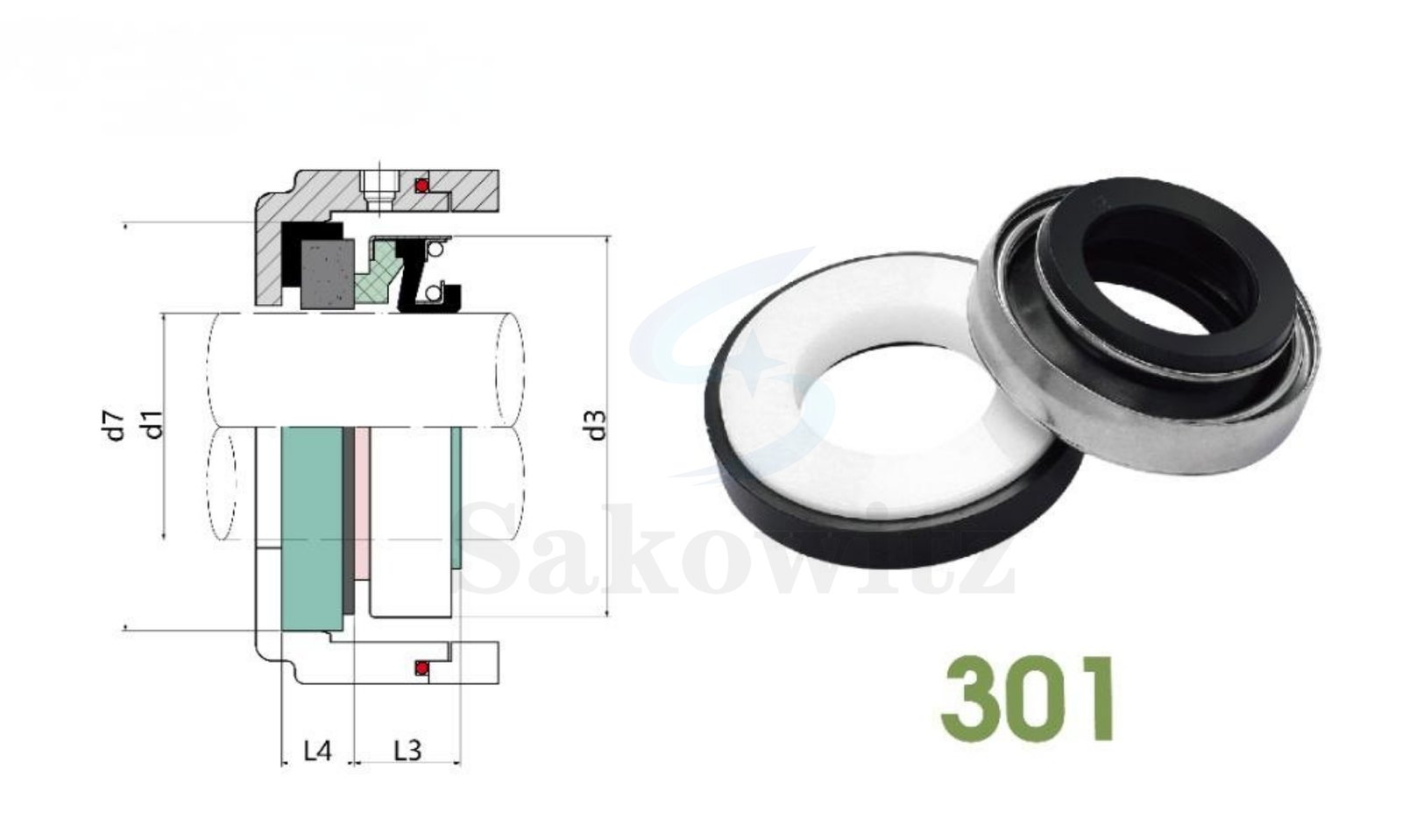

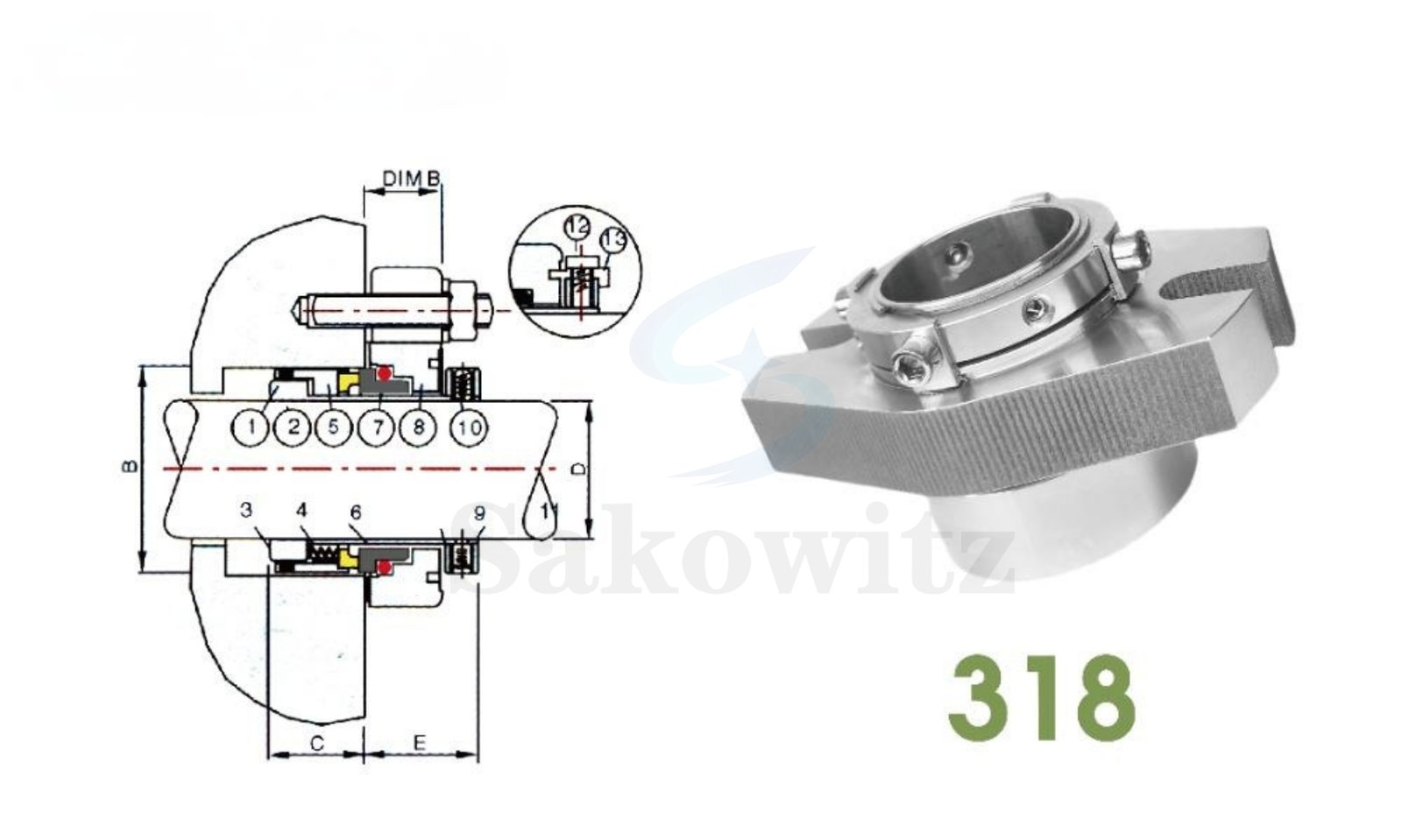

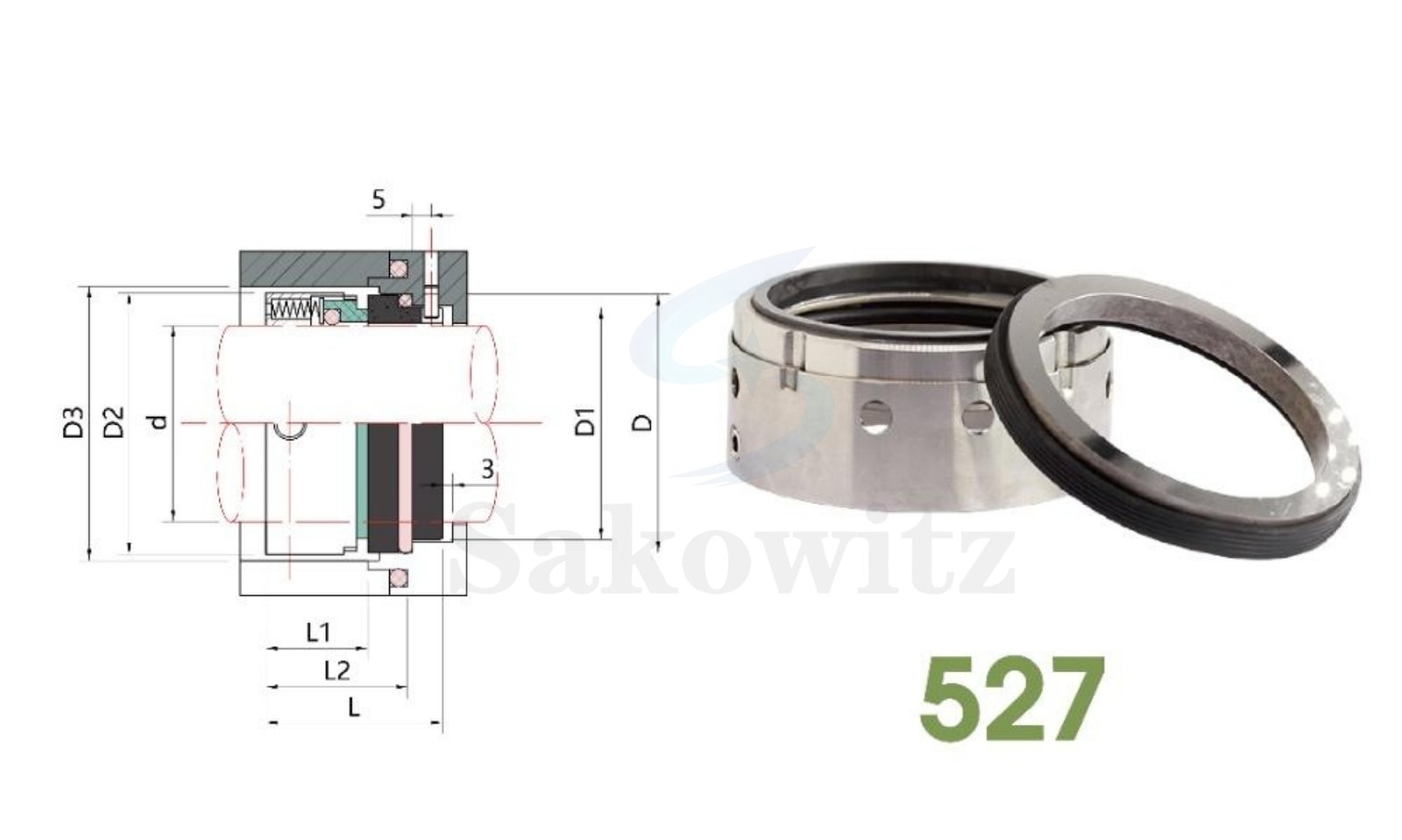

Pump Mechanical Seal Product Series

Свяжитесь с нашими специалистами по механическим уплотнениям, чтобы задать вопросы

Свяжитесь с нами, и наша профессиональная команда Sakowit поможет вам подобрать наиболее подходящее механическое уплотнение для повышения безопасности вашего проекта.

Types of Pump Seals We Manufacture

- Уплотнение картриджа

Suitable for high-pressure chemical pumps, it enables pre-assembly, ensuring more reliable installation and reducing human errors. - O-ring Mechanical Seal

Industrial universal type, suitable for water pumps, chemical pumps, air conditioning circulation pumps, etc. It has a simple structure and stable sealing. - Rubber Bellow Seal

It is commonly used in household pumps, water pumps and submersible pumps, and has excellent compensation capabilities and cost advantages. - Metal Bellow Seal

It is used for the transportation of high-temperature and highly corrosive media, such as oil pumps, acid-base pumps, and solvent pumps. The design without elastomers offers even stronger high-temperature resistance. - Slurry Pump Seal

Designed specifically for slurry, sand-water mixtures, and desulfurization solutions, it features a wear-resistant end face structure and an enhanced cooling system.

Each sealing structure has been optimized by the Sakowitz engineering team, and can be customized according to the pump type, pressure, temperature and medium to ensure long-term stable operation.

Pump Seal Technical Specifications

The following technical parameters illustrate the application scope of the pump seals in various industrial scenarios. The parameter range covers from clean water to highly corrosive chemical media, from normal temperature to high-temperature conditions, helping engineers quickly determine whether the seal meets the project requirements. All data comply with international engineering standards and are applicable to most industrial pump types.

| Параметр | Спецификация / диапазон |

|---|---|

| Давление | ≤ 2–40 bar (depending on seal design and pump type) |

| Температура | -40°C ~ +250°C, suitable for both low- and high-temperature conditions |

| Скорость | ≤ 35 m/s, supports high-speed pump shaft operation |

| Материалы для лица | SiC / WC / Carbon, offering wear resistance and low friction |

| Эластомеры | FKM / EPDM / PTFE / FFKM, compatible with oils, water, and chemical media |

| Металлы | SS304 / SS316 / Duplex / Hastelloy®, providing structural strength and corrosion resistance |

| Стандарты | API 682 / ISO 21049 / CE / FDA, compliant with multi-industry regulations |

Pump Seal Applications Across Key Industries

Used for the transportation of corrosive media such as acids, bases, solvents and resins. The pump’s seals can maintain stable performance under high temperatures and high pressures.

Suitable for media environments containing particles, silt and impurities. The sealing must be wear-resistant, pollution-resistant and capable of continuous operation for a long time.

Seawater is highly corrosive, so mechanical seals made of anti-corrosion materials such as Duplex and Titanium are required.

It should be of a hygienic grade, with low leakage and easy cleaning. The pump seals can meet the hygiene standards (such as FDA).

Used in sterile, vacuum or highly pure medium scenarios. The sealing must ensure no contamination of the medium and be resistant to CIP/SIP cleaning.

Used for high-temperature and high-pressure equipment such as boiler feed pumps and cooling water pumps. The sealing needs to have high stability and a longer service life.

Why Sakowitz Is the Trusted Choice for Pump Seals

When choosing a supplier for pump mechanical seals, reliability and professionalism are of utmost importance. Sakowitz, with its profound engineering capabilities and strict quality system, has become the trusted Pump Seal Manufacturer for global customers.

- Over 30 years of manufacturing and application experience

The accumulation of experience in multiple industries ensures that we can handle complex media, high temperatures, high pressures, and variable working conditions. - Serve customers from over 50 countries worldwide

The product is applied in industries such as chemical engineering, seawater desalination, energy, food, and pharmaceuticals, and has gained long-term trust. - CNC processing accuracy < 2 µm

Higher end face flatness means lower leakage rate and longer service life. - Support for OEM replacement

It can be directly replaced with international brand models, and it has cost advantages as well as a shorter delivery time. - High corrosion-resistant materials + Strict testing procedures

Using materials such as SS316, Duplex, and Hastelloy®, various tests including pressure, dynamic pressure, wear resistance and service life tests were conducted. - Global after-sales support + Rapid delivery capability

Provide technical consultation, selection suggestions, customized services and stable supply chain.

FAQ – Common Questions About Pump Seals

Q1: How long does the lifespan of a pump seal typically last?

It is usually 2 to 5 years. The lifespan depends on the corrosiveness of the medium, temperature, pump speed, and the quality of daily maintenance. Proper lubrication can extend the lifespan by more than 30%.

Q2: Can Sakowitz's seals replace the products of OEM brands?

Sure. We can offer alternatives such as John Crane, EagleBurgmann, Flowserve, etc. The sizes are compatible and can be directly installed without modifying the pump body structure.

Q3: Is it applicable to corrosive or high-temperature media?

Applicable. The material options include SiC, WC, Hastelloy®, PTFE, FFKM, covering various working conditions such as acids, bases, solvents, seawater, and high-temperature oils.

Q4: Can samples and customized services be provided?

Sure. We can provide sample testing, custom drawing services, special size non-standard processing, and offer engineering selection guidance.

Q5: How long does it take for the delivery of the mechanical seals for the pumps?

Standard model ships within 3-7 days, while custom models take 7-15 days. We offer fast delivery and stable supply chain support.

Отправить быструю цитату

Почему нам доверяют 1000+ клиентов

Инженерное превосходство - точность, которая работает

Каждое уплотнение Sakowit разработано, обработано и протестировано для обеспечения максимальной надежности и длительного срока службы - даже в самых жестких условиях эксплуатации.

Проверенная производительность - надежность в любой отрасли

Доверяют инженерам по всему миру за стабильную работу в химических, шламовых и высоконагруженных технологических системах.

Глобальная поддержка - быстрое реагирование, надежное обслуживание

Глобальная сеть и оперативная поддержка обеспечивают получение квалифицированной помощи в нужный момент - где бы вы ни находились.