Mixer Seals Manufacturer

– Provide high-performance sealing solutions for stirring equipment in the chemical, pharmaceutical, food and energy industries.

It can effectively prevent medium leakage, and improve the efficiency of the agitator and the service life of the equipment.

What Makes a Mixer Mechanical Seal Essential for Industrial Mixing Systems

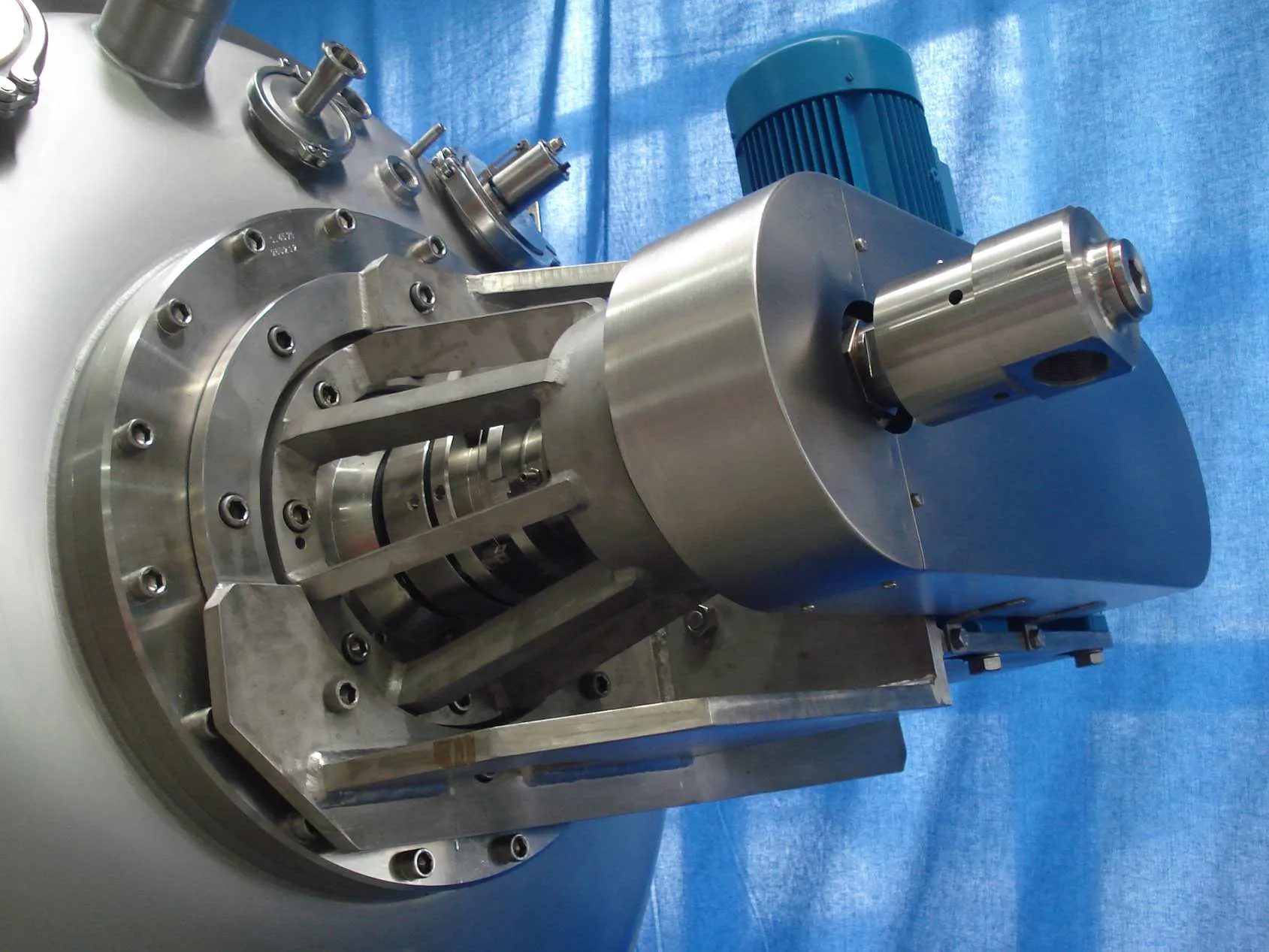

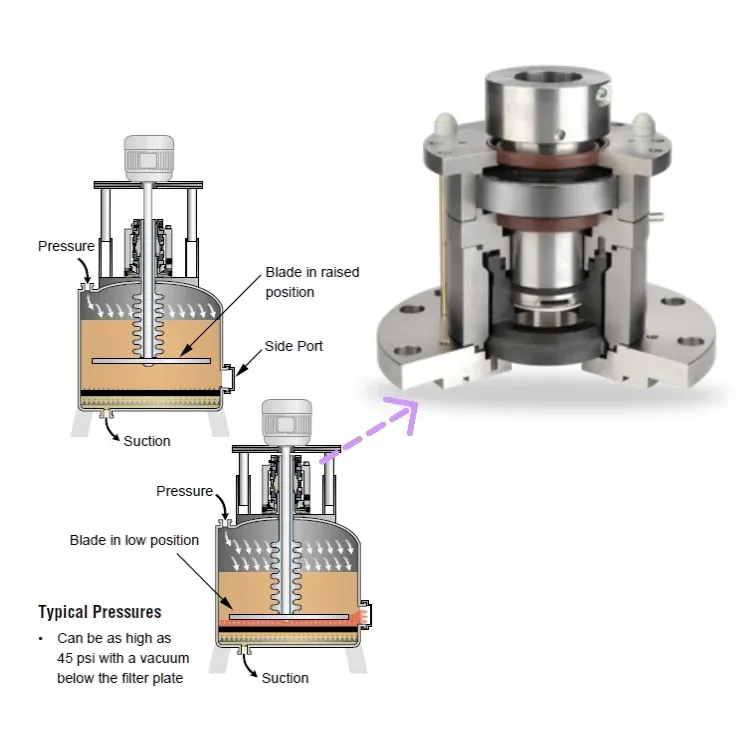

Mixer Mechanical Seal is a key sealing component used in industrial agitators, reactors and mixing equipment. Its main function is to prevent the leakage of liquids or gases and maintain the pressure and cleanliness of the system. It forms a sealing layer through the friction pair between the moving ring and the stationary ring, which can maintain stable sealing performance under rotational, eccentric and vibrating conditions. Compared with the seals used in ordinary pumps, the mechanical seals of agitators have a more robust structure, can adapt to greater axial displacement and complex working conditions, and are widely used in industries such as chemical engineering, pharmaceuticals, food, and petrochemicals to ensure the continuous, safe and efficient operation of equipment.

Benefits of Using Mechanical Seals in Industrial Mixers

Mixer Mechanical Seal can effectively prevents the leakage of harmful or expensive media, ensuring operational safety and compliance with environmental regulations. The mechanical seal can maintain stable performance under complex conditions such as high pressure, high temperature, and vacuum, significantly improving the mixing efficiency and reducing energy consumption.

Compared with traditional packing seals, mechanical seals can reduce friction losses and extend the service life of bearings and the vessel body. Depending on the specific working conditions, users can choose single seal, double seal или cartridge seal designs to meet the diverse sealing requirements in the chemical, pharmaceutical and food industries.

Mixer Seals Product Series

Свяжитесь с нашими специалистами по механическим уплотнениям, чтобы задать вопросы

Свяжитесь с нами, и наша профессиональная команда Sakowit поможет вам подобрать наиболее подходящее механическое уплотнение для повышения безопасности вашего проекта.

Sakowitz Mixer Seal Design Solutions for Industrial Applications

Sakowitz’s products have been meticulously designed to maintain stable performance under high pressure, high temperature and strong corrosive conditions. They are widely used in the chemical, pharmaceutical, food and energy industries.

- Diverse structural types: Offers single-end, double-end, dry-run transformation and jacketed cooling type seals, meeting various reaction conditions.

- Advanced material combinations: The friction surfaces use SiC, Carbon, and Tungsten Carbide; the elastomers use FFKM, PTFE, and EPDM, ensuring corrosion resistance and wear resistance.

- Optimized metal components: Selects materials such as SS316, Hastelloy®, and Titanium to enhance structural strength and chemical resistance.

- Wide range of compatible equipment: Suitable for reaction vessels, mixers, distillation towers, and storage tank systems.

- International standard certifications: All products comply with API 682, ISO 21049, FDA, CE, and ATEX standards.

Technical Specifications of Sakowitz Mixer Seals

The table below lists the core technical parameters provided by Sakowitz as a professional “Mixer Seals Manufacturer”. All sealing products have been optimally designed for high-pressure, high-temperature and sanitary-grade working conditions, ensuring the long-term stable operation and sealing reliability of the mixing equipment.

| Параметр | Спецификация / диапазон | Engineering Notes |

|---|---|---|

| Давление | ≤ 25 бар | Suitable for medium to high-pressure mixing and reactor systems. |

| Температура | -20°C ~ +250°C | Designed to handle high-temperature chemical and thermal processing environments. |

| Скорость | ≤ 20 м/с | Optimized for low to medium-speed agitator and mixer shafts. |

| Материалы для лица | SiC / WC / Carbon | Provides excellent wear resistance and low friction sealing performance. |

| Эластомеры | FKM / FFKM / PTFE / EPDM | Ensures chemical compatibility, flexibility, and long service life. |

| Металлы | SS316 / Duplex / Hastelloy® | Delivers superior mechanical strength and corrosion resistance. |

| Соответствие требованиям | API 682 / ISO 21049 / CE / FDA | Fully compliant with international industrial and hygienic standards. |

Industries & Applications Served by Sakowitz Mixer Seals

Our products have undergone rigorous testing and can maintain outstanding sealing performance and stability in high-pressure, high-temperature, highly corrosive or sanitary environments.

Sakowitz seals are widely used in chemical reaction vessels, mixing tanks and solvent systems. Its highly corrosion-resistant materials can effectively cope with acid, alkali and organic solvent media, ensuring continuous and stable production.

Meet the requirements of aseptic and hygienic working conditions. It is applicable to bioreactors, fermenters and pharmaceutical mixing equipment, and complies with FDA and GMP standards.

Made of food-grade materials, it can be used in stirring systems for dairy products, vegetable oils, syrups, etc., ensuring the cleanliness and safety of the products.

Designed for high-viscosity emulsification and vacuum mixing processes, it features a stable and wear-resistant seal, preventing contamination and leakage.

Suitable for sludge stirring, chemical dosing and other systems, and can operate for a long time in particulate matter or chemical media.

Providing specialised sealing solutions resistant to solvents and abrasion, ensuring long-term leak-free operation for high-viscosity resin and coating production lines.

Why Global Manufacturers Choose Sakowitz Mixer Seals

Саковиц, как профессионал Mixer Seals Manufacturer, with over thirty years of experience in seal design and manufacturing, provides high-precision and long-lasting sealing solutions for global industrial mixing equipment. We focus on engineering technology as the core, offering customers products and services that are both reliable, efficient, and economical.

We have over 30 years of industry experience, familiar with various complex working conditions and international standards. We can customize the most optimal sealing solutions for different mixing systems. Currently, our products have been successfully applied in over 50 countries worldwide, performing well in the fields of chemical engineering, pharmaceuticals, food, and energy.

All sealed products have undergone CNC precision processing, with the flatness controlled within 2 micrometers, ensuring that the end faces of the moving and static rings fit perfectly, thereby reducing the risks of wear and leakage. Sakowitz supports OEM replacement and customized design, and is compatible with mainstream mixing equipment brands.

We select high-performance materials (such as Hastelloy®, Duplex, food-grade stainless steel, etc.), which possess excellent corrosion resistance, high-temperature resistance and hygienic properties. Additionally, Sakowitz offers global engineering support and rapid delivery, ensuring that customers receive reliable technical support throughout the entire project cycle.

FAQ – Common Questions About Mixer Seals

Q1: Can Sakowitz mixer seals replace OEM brands like John Crane or Flowserve?

Certainly. We offer standard replacement solutions compatible with mainstream OEM models, and can also provide bespoke engineering designs tailored to your equipment to ensure perfect fitment and enhanced sealing performance.

Q2: Are your mixer seals suitable for vacuum or pressure reactors?

Certainly. Our seals are specifically engineered for vacuum and high-pressure environments, maintaining a stable seal under positive pressure, negative pressure, and high-temperature conditions to prevent leakage.

Q3: What is the lifespan of a mixer seal?

Typically 3–5 years, depending on the type of medium, operating temperature, pressure, and equipment maintenance. For high-load conditions, Sakowitz can provide reinforced or double-ended seal solutions to extend the service life.

Q4: Do you provide food-grade and FDA-compliant seals?

Yes. We can utilise materials compliant with FDA and EU 1935/2004 standards, such as food-grade PTFE, EPDM, and FKM, ensuring safe and reliable application in hygienic process systems for food, beverage, and pharmaceutical industries.

Отправить быструю цитату

Почему нам доверяют 1000+ клиентов

Инженерное превосходство - точность, которая работает

Каждое уплотнение Sakowit разработано, обработано и протестировано для обеспечения максимальной надежности и длительного срока службы - даже в самых жестких условиях эксплуатации.

Проверенная производительность - надежность в любой отрасли

Доверяют инженерам по всему миру за стабильную работу в химических, шламовых и высоконагруженных технологических системах.

Глобальная поддержка - быстрое реагирование, надежное обслуживание

Глобальная сеть и оперативная поддержка обеспечивают получение квалифицированной помощи в нужный момент - где бы вы ни находились.