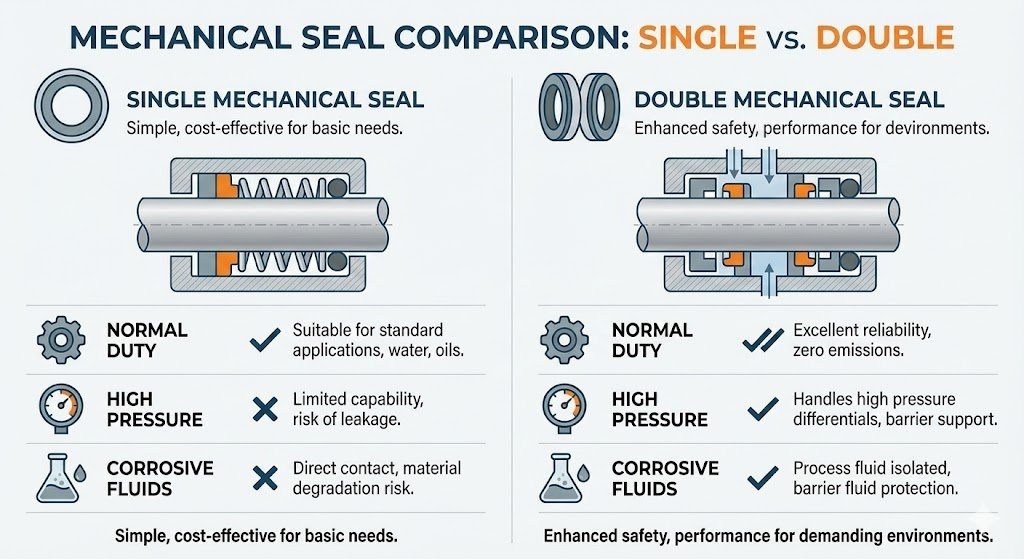

Choosing between a single mechanical seal and a selo mecânico duplo is one of the most common challenges in pump system design. Selecting the wrong type can lead to leakage, downtime, contamination, and increased maintenance costs.

This guide breaks down the differences, advantages, and ideal application scenarios—helping engineers and buyers make the right decision every time.

1. What Is a Single Mechanical Seal?

A single mechanical seal has one sealing interface:

-

A rotating face

-

A stationary face

The pumped medium provides lubrication and cooling of the seal faces.

✔ Advantages

-

Low cost

-

Simple installation

-

Lower flush requirements

-

Suitable for clean, lubricating fluids

✖ Limitations

-

Not suitable for hazardous, abrasive, or poorly lubricating media

-

Sensitive to dry running

-

Shorter life in high-pressure or high-temperature systems

Best For

-

Water pumps

-

Cooling systems

-

Light chemicals

-

General industrial service

2. What Is a Double Mechanical Seal?

A selo mecânico duplo uses two sets of seal faces—either:

-

Back-to-back

-

Face-to-face

-

Tandem (most common)

A barrier or buffer fluid is used to protect the mechanical seal and isolate process media.

✔ Advantages

-

Highest reliability

-

Handles corrosive, abrasive, or toxic media

-

Protects seals from dry running

-

Ideal for slurry, solvents, polymers, and critical processes

✖ Limitations

-

Higher cost

-

Requires seal support system (API Plan 52/53A/53B)

Best For

-

Petrochemical applications

-

Toxic or flammable fluids

-

High-temperature reactors (如 M481K 使用场景)

-

Slurry and abrasive pumping

3. Single vs Double Seals: Key Differences

| Feature | Selo único | Vedação dupla |

|---|---|---|

| Leakage Control | Good | Excellent |

| Media Compatibility | Clean fluids | Hazardous, corrosive, abrasive |

| Dry Running Tolerance | Low | High |

| Cost | Low | Higher |

| Maintenance | Simple | Moderate |

| Required Flush | Usually no | Required (barrier fluid) |

| Safety | Medium | Very high |

Double seals are often required by API 682, FDAe industrial safety regulations for hazardous applications.

4. When Should You Choose a Single Mechanical Seal?

Choose a single seal when:

-

The fluid is clean, non-abrasive, non-corrosive

-

Operating pressure < 25 bar

-

No harmful emissions risk

-

Low temperature (<120°C)

-

Cost is a primary factor

Typical applications:

-

HVAC pumps

-

Cooling water

-

Food-grade CIP return lines

-

Light-duty chemical transfer

5. When Should You Choose a Double Mechanical Seal?

Choose a double seal when the application involves:

-

Toxic, hazardous, or explosive fluids

-

Abrasive slurries or crystallizing media

-

High temperature (>150°C)

-

High pressure (>25 bar)

-

Vacuum conditions

-

Fluids with poor lubricating ability

Industries that commonly require double seals:

-

Petrochemical

-

Farmacêutico

-

Pesticides & specialty chemicals

-

High-temperature reaction kettles (M481K 典型客户)

-

Desalination and wastewater treatment

6. Cost Comparison: Is a Double Seal Worth It?

Even though the initial cost of a double seal is higher, it often results in:

-

60–80% fewer seal failures

-

Dramatic reduction in leakage

-

Longer pump uptime

-

Lower environmental risk

-

Lower overall cost of ownership

This is why many plants shift to cartridge double mechanical seals for critical lines.

7. Why Cartridge Seals Are the Best Choice for Both Types

Cartridge seals—like Sakowitz’s M481K and XD-series—provide:

-

Pre-set face compression

-

Correct alignment

-

Faster installation

-

Lower leakage

-

Higher reliability

They eliminate most human installation errors, which cause 40% of seal failures.

8. Choosing the Right Seal: Engineer Checklist

Before selecting a seal type, confirm:

-

Fluid characteristics (abrasive? corrosive?)

-

Pressure & temperature

-

Pump speed

-

Environmental regulations

-

Plant safety requirements

-

Maintenance capability

If any factor is uncertain → choose double seal for safety.

Conclusion: Which One Should You Choose?

| If your system is… | Choose |

|---|---|

| Clean water, low risk | Single seal |

| Toxic, abrasive, corrosive media | Double seal |

| High temperature reactors | Double seal (M481K) |

| Safety-critical process | Double seal |

| Budget-limited general service | Single seal |

For most industrial plants, double mechanical seals offer the best protection and lowest long-term cost—especially when dealing with hazardous or high-temperature media.