O-Ring Mechanical Seal Manufacturer

– Engineered for durability, chemical resistance, and leak-free operation in industrial environments.

Sakowit specializes in high-performance O-ring mechanical seals designed for pumps, compressors, and fluid systems.

How O-Ring Mechanical Seals Provide Reliable Shaft Sealing

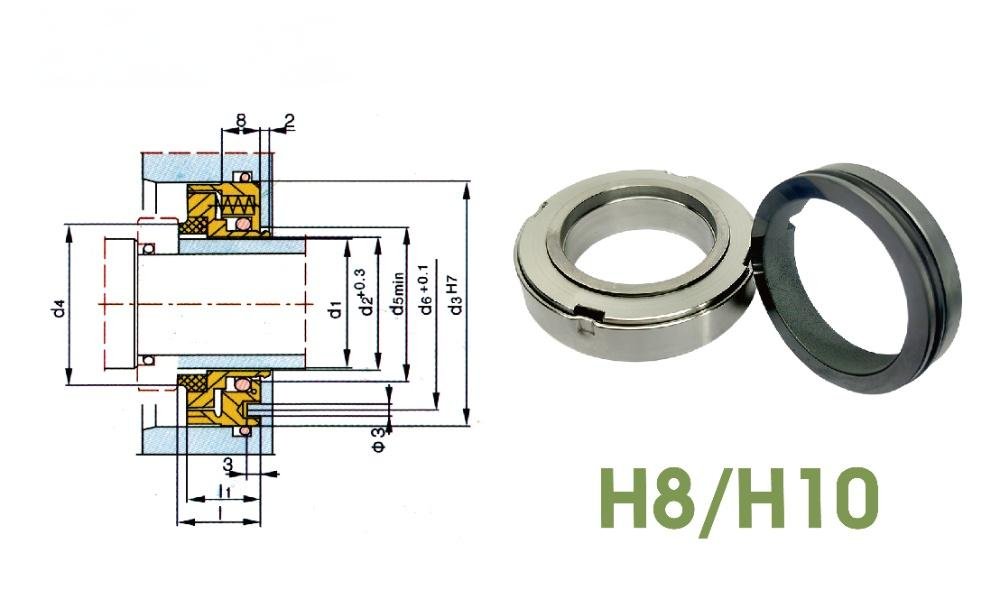

O-ring mechanical seal is a sealing structure that provides secondary sealing function through the elastic O-ring. It consists of the moving ring, the stationary ring, the spring, and the O-ring, and achieves axial dynamic sealing through the precise alignment of the end faces, preventing the leakage of the medium. The O-ring mechanical seal has excellent redundancy and elastic recovery capabilities, and can automatically adapt to axial displacement and wear, thereby extending the service life of the seal.

The O-ring material is usually selected from NBR, FKM, EPDM or PTFE. It can be customized according to the properties of the medium and the temperature requirements, and can maintain stable sealing performance in water, oil, chemical liquids and mild corrosive media.

Why O-Ring Mechanical Seals Are the Preferred Choice for Industrial Pumps

The O-ring mechanical seal, due to its simple structure, reliable sealing performance, and low maintenance cost, has become the standard configuration for industrial pumps. It achieves automatic compensation and sealing surface adhesion through the elastic deformation of the O-ring. Even under high pressure, temperature changes, or axial vibration conditions, it can maintain a stable sealing effect. Compared with traditional packing seals or lip seals, the O-ring mechanical seal can significantly reduce the leakage rate (up to 90% reduction), and reduce energy consumption and shaft wear, thereby extending the service life of the equipment.

Furthermore, its structure is highly versatile and can be compatible with various pump types and material combinations, making it an ideal choice for industries such as chemical engineering, pharmaceuticals, energy, and water treatment.

Entre em contato com nossos especialistas em selos mecânicos para tirar dúvidas

Entre em contato conosco e nossa equipe profissional da Sakowit poderá ajudá-lo a encontrar o selo mecânico mais adequado para aumentar a segurança do seu projeto.

Sakowit Engineering Solutions for High-Performance O-Ring Mechanical Seals

Sakowit has over thirty years of experience in sealing engineering design and manufacturing, dedicated to providing high precision, long lifespan, and zero leakage sealing solutions for rotating equipment such as pumps, mixers, and compressors. Our O-ring mechanical seals, combined with optimized structural design and selection of high-performance materials, ensure stable operation in high-pressure, high-speed, and chemically corrosive environments.

Diverse Structural Design

Offer single-ended, double-ended, balanced and unbalanced structures, which can be selected according to the operating pressure of the equipment and the characteristics of the medium, ensuring both reliable sealing and cost efficiency.

High-quality Material Combination

The sealing end face is made of SiC / WC / Carbono material, combined with NBR, FKM, EPDM and other elastomers, and it possesses excellent wear resistance, heat resistance and corrosion resistance properties.

Wide Range of Applicable Equipment Types

Suitable for various industrial rotating equipment, including centrifugal pumps, mixing reaction vessels, compressors and vacuum systems. It can operate stably in different media (such as water, oil, solvents and corrosive liquids).

International Standards and Quality Certification

The design and testing strictly follow international standards such as API 682 and ISO 21049, and have obtained CE/ROHS certifications to ensure product quality and safety.

Technical Specifications of Sakowitz O-Ring Mechanical Seals

Sakowit O-ring mechanical seals are precisely designed and strictly tested to ensure stable sealing performance under high pressure, high speed and chemical medium conditions. By adopting high-hardness end face materials and corrosion-resistant metal components, low-friction, long-life and zero-leakage operation is achieved in industrial pump and compressor systems.

| Category | Especificação / Faixa | Descrição |

|---|---|---|

| Rotary Ring Face | Carbono / Carbeto de silício (SiC) / Carbeto de tungstênio (TC) | Provides high hardness, wear resistance, and stable performance under friction. |

| Stationary Ring Face | Silicon Carbide (SiC) / Tungsten Carbide (TC) | Ensures corrosion resistance and dimensional stability of sealing surfaces. |

| Elastômeros | Viton® / PTFE | High chemical and temperature resistance for reliable secondary sealing. |

| Springs | Aço inoxidável SS304 / SS316 | Corrosion-resistant spring structure maintains constant face pressure. |

| Metal Parts | Aço inoxidável SS304 / SS316 | Ensures mechanical strength and long-term structural integrity. |

| Pressão | ≤ 2,5 MPa | Suitable for medium- to high-pressure pump and hydraulic systems. |

| Temperatura | -40°C to +180°C | Operates reliably under thermal fluctuation and varied fluid temperatures. |

| Linear Speed | ≤ 35 m/s | Designed for high-speed rotating shafts with minimal wear. |

| Mídia aplicável | Oil, Water, Weak Acid / Alkali | Compatible with water, oils, and light corrosive industrial fluids. |

Key Industries and Applications of O-Ring Mechanical Seals

Sakowit O-ring mechanical seals are widely used in pumps, compressors and fluid equipment in various industries due to their excellent sealing performance, material compatibility and long service life.

It is used for chemical pumps, reaction vessels and process conveying systems. O-ring materials (such as FKM and PTFE) can withstand acids, alkalis and solvents. Maintain stable sealing performance in high temperatures and corrosive media.

Suitable for centrifugal pumps, gear pumps, vacuum pumps and compressors. The O-ring structure automatically compensates for axial misalignment and wear. Reduces leakage, minimises friction and extends equipment service life.

Widely employed in water supply pumps, sewage pumps and dewatering systems. Exhibits strong resistance to water and contamination, preventing medium leakage and motor contamination. Features a compact structure and straightforward maintenance, making it suitable for continuous operation conditions.

For crude oil transportation, gas compression and refining installations. O-ring seals withstand high pressures (up to 2.5 MPa) and high-temperature media. Metal components utilise SS316 / Duplex for corrosion resistance and stress crack resistance.

Suitable for sanitary pumps, agitators and aseptic systems. Manufactured from FDA/USP Class VI-compliant elastomer materials to ensure food-grade safety. Smooth and easy to clean, preventing microbial accumulation.

For hydraulic steering gear, cooling pumps and seawater circulation systems. Constructed from corrosion-resistant metals (such as Hastelloy and SS316) to withstand salt spray and humid thermal environments.

Why Global Engineers Trust Sakowitz O-Ring Mechanical Seals

Sakowit has become a world-leading manufacturer of O-ring mechanical seals, drawing upon over three decades of expertise in seal design and production. We specialise in precision manufacturing and material innovation, delivering stable, reliable and customisable sealing solutions for industrial pumps, compressors and fluid systems.

30+ Years of Engineering Excellence

Sakowit possesses over thirty years of accumulated expertise in sealing technology, having amassed extensive application experience across liquid, gas and high-pressure sealing domains. We continually refine our designs to ensure every seal is capable of withstanding the complex operating conditions encountered in modern industry.

Global Presence in 50+ Countries

Our products have been operating reliably in over 50 countries and within more than 15,000 systems. From chemical plants to offshore platforms, Sakowitz seals provide dependable support for engineering projects worldwide.

Fabricação de CNC de precisão

All seals are CNC precision-machined with seal face flatness controlled to <2 µm, ensuring zero leakage and low wear. This manufacturing precision significantly enhances seal longevity and system efficiency.

Certified Material Quality

All products are manufactured from high-quality, corrosion-resistant and wear-resistant materials (such as SiC, Hastelloy® and FKM). They are certified to standards including API 682, ISO 21049, CE and RoHS, ensuring quality and safety.

OEM Replacement & Custom Engineering

Sakowit can provide OEM-compatible seals or bespoke solutions tailored to the customer’s equipment model. Whether for new project designs or retrofitting existing pumps, we swiftly identify the optimal solution.

Frequently Asked Questions about O-Ring Mechanical Seals

Q1: What is the function of the O-ring in a mechanical seal?

O-rings serve as secondary sealing elements within mechanical seals. They prevent axial leakage of the medium through elastic deformation while compensating for minor shaft displacement and wear on the sealing surfaces.

Q2: Can Sakowitz O-ring seals replace my current pump seal?

Certainly. Sakowit offers both OEM-compatible and custom-designed mechanical seals. We can rapidly match and optimise designs based on pump model, shaft diameter, and medium characteristics.

Q3: What is the expected service life of O-ring mechanical seals?

Typical service life is 2–5 years, depending on pressure, rotational speed, medium and maintenance conditions. With good lubrication and correct installation, service life may be extended by over 50%.

Q4: Do you supply food-grade or chemical-resistant versions?

We utilise FDA-certified materials such as FKM and PTFE to ensure safety and reliability within the food, pharmaceutical, and chemical industries. All seals comply with CE/RoHS/ISO 21049 international standards.

Envie uma cotação rápida

Por que temos a confiança de mais de 1.000 clientes

Excelência em engenharia - Precisão que funciona

Cada vedação da Sakowit é projetada, usinada e testada para proporcionar máxima confiabilidade e longa vida útil, mesmo nos ambientes mais difíceis.

Desempenho comprovado - confiável em todos os setores

Com a confiança de engenheiros de todo o mundo para um desempenho consistente em sistemas de processos químicos, de polpas abrasivas e de alta demanda.

Suporte global - Resposta rápida, serviço confiável

A rede global e o suporte ágil garantem que você receba ajuda especializada quando precisar, onde quer que esteja.