Introduction: Why Mechanical Seals Fail Before They Are Installed

Mechanical seals are precision components, but many seal failures begin long before installation.

Improper storage and careless handling can cause hidden damage that leads to leakage, shortened service life, or immediate failure after start-up.

Common problems such as cracked seal faces, hardened elastomers, or distorted components are often traced back to incorrect storage conditions or poor handling practices.

This guide explains how to store and handle mechanical seals correctly to avoid shelf damage and installation issues.

Why Proper Storage and Handling Matter

Mechanical seals rely on:

-

Ultra-flat seal faces

-

Elastic secondary seals

-

Precisely calibrated spring forces

Even minor damage caused during storage or handling can:

-

Destroy face flatness

-

Reduce elastomer elasticity

-

Cause uneven face loading

-

Lead to early leakage

Many “new seal failures” are actually storage-induced failures.

Correct Storage Conditions for Mechanical Seals

Recommended Storage Environment

-

Clean, dry, and dust-free

-

Temperature typically between 5°C and 25°C

-

Low humidity, no condensation

-

Away from direct sunlight and UV exposure

What to Avoid

-

Extreme temperatures

-

High humidity

-

Chemical vapors

-

Direct sunlight

-

Storage near motors or ozone-generating equipment

Elastomers such as NBR, EPDM, and FKM are particularly sensitive to heat, ozone, and UV exposure.

Shelf Life Considerations (Often Ignored)

Elastomer Aging

Even when unused, elastomers age over time:

-

Loss of elasticity

-

Hardening or cracking

-

Reduced sealing performance

Best Practices

-

Follow FIFO (First In, First Out) inventory management

-

Label seals clearly with storage date

-

Avoid long-term storage without inspection

A “new” seal stored improperly for years may perform worse than a properly stored older seal.

Proper Handling Practices for Mechanical Seals

Handling Do’s

-

Handle seals with clean hands or gloves

-

Keep seal faces protected until installation

-

Use original packaging whenever possible

-

Place seals on clean, soft surfaces

Handling Don’ts

-

Do not touch seal faces directly

-

Do not drop or impact seals

-

Do not stack heavy items on seal packages

-

Do not disassemble seals before installation

Seal face materials such as ceramic, silicon carbide, and tungsten carbide are brittle and can crack from minor impacts.

Transportation and Internal Movement

Even short-distance movement inside a plant can cause damage.

Best Practices

-

Use padded containers

-

Secure seals to prevent movement

-

Avoid vibration and shock during transport

-

Keep seals upright in original orientation

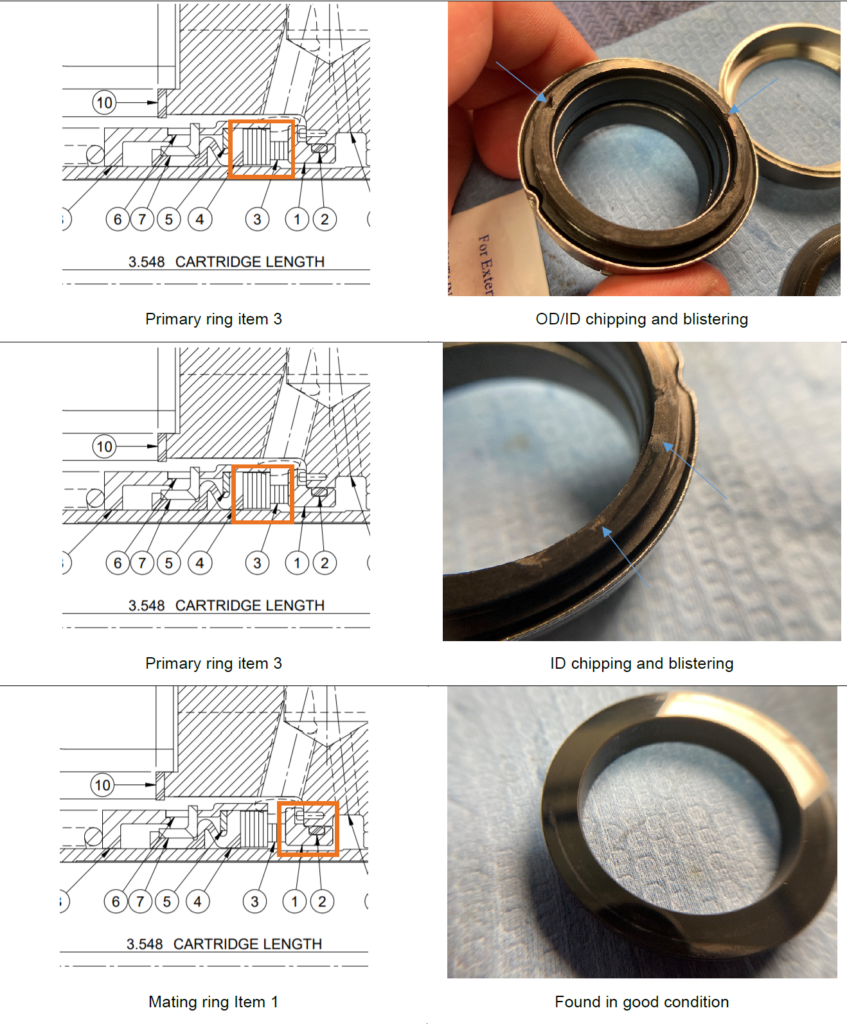

Pre-Installation Inspection Checklist

Before installation, always:

-

Inspect seal faces for chips or scratches

-

Check elastomers for cracks or hardening

-

Verify spring or bellows movement

-

Ensure no contamination on sealing surfaces

If any abnormality is found, do not install the seal.

Common Storage and Handling Mistakes

-

Storing seals in open warehouse environments

-

Exposing seals to sunlight or heat

-

Touching seal faces with bare hands

-

Assuming factory packaging guarantees protection forever

-

Installing seals without inspection

These mistakes often result in immediate leakage or short service life.

Special Considerations for Cartridge Mechanical Seals

Cartridge seals simplify installation but still require care:

-

Do not remove setting clips prematurely

-

Avoid applying axial force to the cartridge

-

Keep all shipping spacers in place until installation

Improper handling can disturb factory settings and cause misalignment.

FAQ: Mechanical Seal Storage and Handling

Q1: Can mechanical seals be stored vertically?

Yes, if properly supported and protected from tipping or impact.

Q2: How long can mechanical seals be stored?

Shelf life depends mainly on elastomer type and storage conditions. Periodic inspection is recommended.

Q3: Should seals be cleaned before installation?

Only if contamination is present, and only using approved, lint-free methods.

Final Thoughts: Seal Reliability Starts Before Installation

Mechanical seal reliability begins in the warehouse, not at start-up.

Correct storage and careful handling preserve seal integrity, prevent hidden damage, and significantly improve installation success.

A disciplined approach to storage and handling is one of the lowest-cost ways to improve seal reliability.

Call to Action (CTA)

👉 Need guidance on storing or handling mechanical seals in your facility?

Share your storage conditions or handling process. Our technical team can help you establish best practices to avoid shelf damage and installation issues.

👉https://sakowit.com/mechanical-seal-installation-guide-best-practices-to-prevent-early-failure/