Mechanical Seals for Chemical Pumps

– Engineered Reliability for Corrosive & Hazardous Fluids

Over 35 Years of Expertise | API 682, ANSI, and DIN Seal Solutions for Pumps, Compressors & Agitators

Why Mechanical Seals for Chemical Pumps?

When chemical pumps handle highly corrosive, toxic, high-temperature, or volatile media, traditional packing seals cannot guarantee reliable sealing and safety. Mechanical seals effectively prevent leakage, ensuring long-term stable and safe operation of the equipment.

The primary advantages of using mechanical seals for chemical pumps are as follows:

- Zero-leakage operation — Prevents chemical media leakage, ensuring personnel and environmental safety

- Long service life and low maintenance — Reduces downtime and spare part consumption

- Corrosion and high-temperature resistance — Suitable for complex chemical media such as acids, alkalis, and solvents

- Compliance with international standards — Meets requirements including API 682 / ISO 21049 / FDA

- Reduced lifecycle costs — High efficiency, low energy consumption, and reliable operation

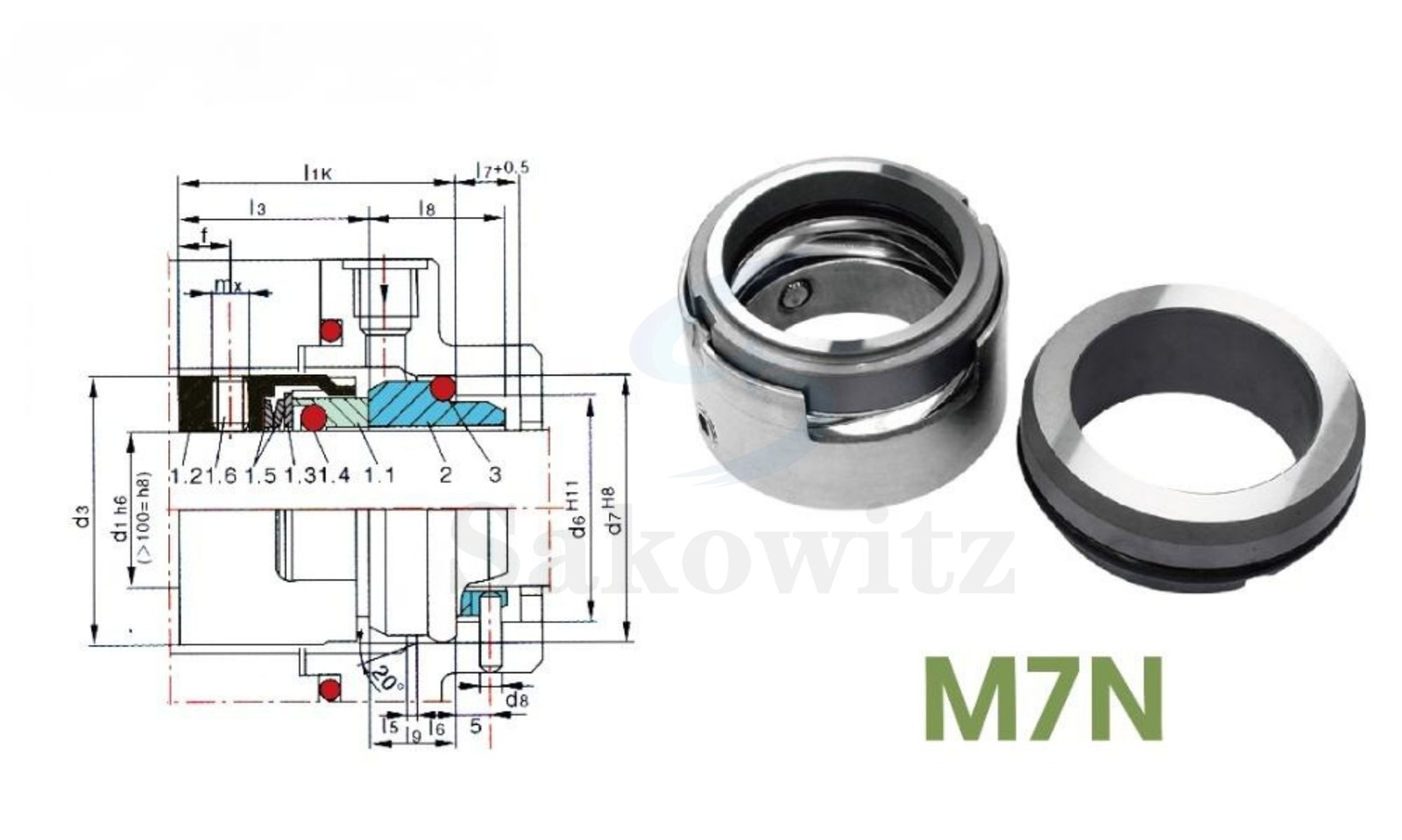

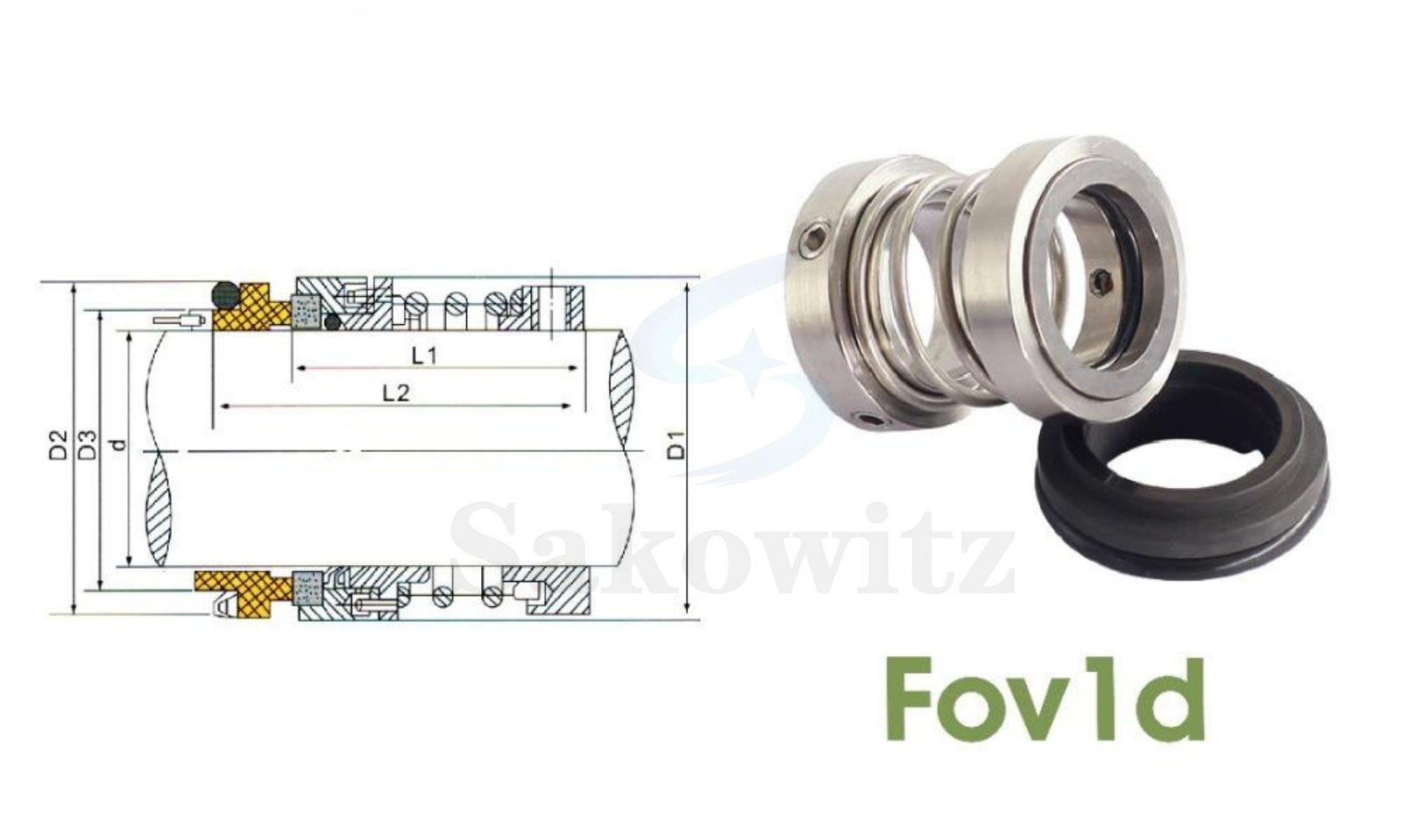

Chemical Pump Mechanical Seal Series

Sakowit offers multiple series of high-performance mechanical seals specifically designed for the chemical, petrochemical, pharmaceutical, and fine chemical industries. All seals comply with API 682 / ISO 21049 standards and are suitable for chemical pumps handling acids, alkalis, solvents, corrosive liquids, and high-temperature media.

Performance Range

| Parâmetro | Faixa / Especificação |

|---|---|

| Diâmetro do eixo | 25 mm – 100 mm (larger sizes available on request) |

| Pressão | Até 25 bar (363 psi) |

| Temperatura | -40°C to +220°C (special designs up to +400°C) |

| Velocidade de rotação | Up to 16 m/s |

| Materiais da face da vedação | Silicon Carbide (SiC), Tungsten Carbide, Carbon Graphite |

| Secondary Seals | FKM (Viton®), EPDM, PTFE, FFKM (Kalrez®) |

| Componentes metálicos | 316 Stainless Steel, Hastelloy® C-4, Alloy 20 |

| Padrões aplicáveis | API 682 / ISO 21049 / FDA / USP Class VI |

| Seal Arrangements | Single, Double (Tandem / Back-to-Back), Cartridge |

| Cooling / Support Plans | API Plan 11, 32, 52, 53A/B/C (optional) |

Mechanical Seals vs Gland Packing — Engineering Comparison Table

| Parâmetro | Gland Packing | Mechanical Seal | Engineering Advantage |

|---|---|---|---|

| Leakage Control | Continuous leakage, controlled by tightening | Virtually zero leakage with lubricating film | ✅ Leak-free operation, meets environmental standards |

| Shaft Wear | Causes significant shaft wear due to friction | Non-contact design, protects shaft surface | ✅ Extends shaft and sleeve life |

| Energy Consumption | High friction and power loss | Low friction, 5–10% energy savings | ✅ Energy-efficient and smoother operation |

| Maintenance Interval | Frequent adjustment and replacement required | 2–5 years continuous operation | ✅ Long service life, minimal maintenance |

| High Temperature & Pressure Capability | Prone to leakage and failure under extreme conditions | Operates up to 25 bar / 400°C | ✅ Reliable under severe chemical conditions |

| Self-Compensation | No self-adjustment, rapid performance loss | Springs or bellows compensate for wear automatically | ✅ Consistent sealing performance |

| Environmental & Safety Compliance | Possible external leakage and safety risk | Fully sealed, prevents toxic or flammable emissions | ✅ Complies with EPA / ATEX / API 682 standards |

| Installation Complexity | Requires manual packing and adjustment | Pre-assembled cartridge design for quick installation | ✅ Easy, precise installation |

| Lifetime Cost | Low upfront cost but high maintenance cost | Slightly higher initial cost, 30–50% lower total cost | ✅ Lower total cost of ownership (TCO) |

| Compliance & Standards | Does not meet modern emission standards | Meets API 682 / ISO 21049 / FDA standards | ✅ Certified and globally compliant |

Applications of Chemical Pump Mechanical Seals

Sakowit Mechanical seals are widely trusted in chemical, petrochemical, pharmaceutical, and water treatment plants worldwide. Each seal is meticulously designed to ensure safety, compliance with environmental regulations, and long-term reliable operation even in the most demanding chemical process environments.

- Typical Media: Sulfuric acid, hydrochloric acid, sodium hydroxide, nitric acid, ethanol, toluene, acetone, resins, adhesives.

- Sealing Requirements: High corrosion resistance, anti-crystallization, dry friction protection.

- Recommended Seals: CRT, WM300, MBWT, CTX-D.

- Typical Equipment: Chemical process pumps, reactor circulation pumps, agitators.

- Typical Media: Hydrocarbons, aromatics, benzene compounds, diesel fuel, solvent oils.

- Sealing Requirements: High temperature and pressure, zero leakage, API 682 double-ended structure.

- Recommended Seals: MBWT, UFLWT, CRT-D.

- Typical Equipment: API 610 process pumps, oil transfer pumps, hydrogenation unit pumps.

- Typical Media: Active ingredients, alcohols, cleaning solutions (CIP/SIP), steam, sterile water.

- Sealing Requirements: FDA/USP Class VI materials, easy to clean, temperature shock resistance.

- Recommended Seals: U184, SLC, CRT-SN.

- Typical Equipment: Reactors, agitators, fermenters, centrifugal pumps.

- Typical Media: Cleaning agents, sugar solutions, flavor additives, ethanol, oils and fats.

- Sealing Requirements: Food-grade materials, high-temperature sterilization capability, easy cleaning.

- Recommended Seals: RB100, U184, WM200.

- Typical Equipment: Sanitary pumps, agitators, mixing equipment.

- Typical Media: Hot oil, coolant, thermal oil, steam.

- Sealing Requirements: High-temperature pressure resistance, long-term operational stability.

- Recommended Seals: MBWT, WM700, API-S.

- Typical Equipment: Circulation pumps, boiler feedwater pumps, thermal oil pumps.

- Typical Media: Sodium hypochlorite, ammonia water, spent acids, spent alkalis, solids-laden liquids.

- Sealing Requirements: Corrosion resistance, wear resistance, crystallization and clogging prevention.

- Recommended Seals: CTX, RB100, WM300.

- Typical Equipment: Circulation pumps, sewage pumps, chemical dosing pumps.

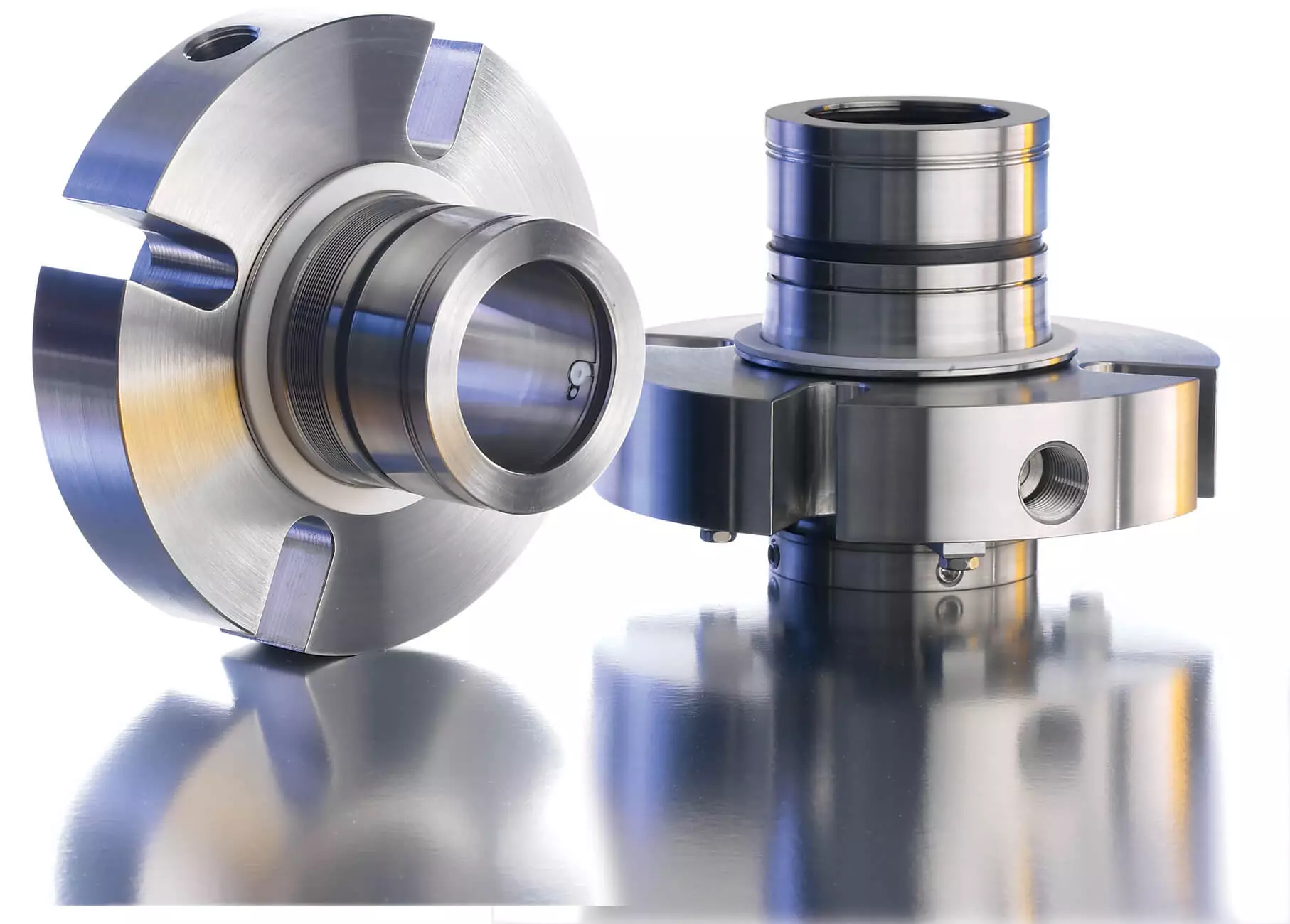

Why Choose Sakowit Mechanical Seals for Chemical Pumps?

Choosing sakowit mechanical seals for chemical pumps means opting for higher safety standards, extended service life, reduced maintenance costs, and robust global support.

- Made in China, Precision and Reliability: All seals are designed and manufactured by Acumen in the UK, ensuring consistent quality and compliance with international standards.

- Engineered for Chemical Processes: Developed for acids, alkalis, solvents, and high-temperature corrosive media, guaranteeing long-term leak-free operation in demanding chemical environments.

- Premium Materials: Utilizes corrosion-resistant materials including SiC, tungsten carbide, PTFE, and FKM, compliant with API 682 / ISO 21049 / FDA standards.

- Comprehensive product range: Offers single-end, double-end, cartridge, bellows, and reactor seals to cover diverse chemical pump and process requirements.

- Customizable design: Supports non-standard designs and rapid delivery based on customer pump specifications, media, and structural drawings.

- Simple installation and extended maintenance intervals: Cartridge pre-assembly minimizes fitting errors, with maintenance cycles lasting 2–5 years.

- Reliable Performance with Rigorous Testing: Each seal undergoes pressure, leakage, and torque testing before shipment to ensure dependable operation.

- Rapid Response: Global technical support, expedited delivery, and after-sales service provide customers with complete peace of mind.

Frequently Asked Questions about Chemical Pumps Mechanical Seals

Why are Mechanical Seals Essential for Chemical Pumps?

A: Standard HEPA filter models typically ship within 7–10 business days.

Custom products require approximately 2–3 weeks for delivery, depending on size and configuration.

With multiple automated production lines and a stable supply chain system, we can swiftly fulfill bulk orders and urgent projects.

How Do I Select the Right Seal for My Chemical Pump?

Because chemical media are typically corrosive, toxic, or flammable, any leakage can pose safety and environmental risks. Mechanical seals ensure zero leakage operation, compliance with environmental regulations, and reduced maintenance costs.

How Can I Prevent Premature Seal Failure in a Chemical Pump?

- Keep the cooling or flushing system clean to prevent crystallization and deposits.

- Ensure proper shaft alignment accuracy and installation compression.

- Avoid dry running or cavitation.

What Is the Typical Service Life of a Mechanical Seal?

Under normal chemical process conditions, Sakowit seals can operate reliably for 2–5 years.

Lifespan can be further extended by using high-end materials (such as SiC/FFKM) or implementing a cooling system.

Envie uma cotação rápida

Por que temos a confiança de mais de 1.000 clientes

Professional Cleanroom System Integration Capabilities

As a specialized Cleanroom Equipment Manufacturer, we not only produce individual equipment but also possess system-level clean environment engineering capabilities.

Verifiable Product Quality and Manufacturing Reliability

Our products strictly adhere to international cleanroom standards and quality control systems throughout design and manufacturing. Each unit undergoes HEPA/ULPA efficiency testing, airflow and velocity testing, noise and energy consumption verification before shipment. We provide CNAS, SGS, or third-party certification reports for full traceability.

Global Customer Trust and Ongoing Technical Support

We serve a worldwide client base, with products exported to over 20 countries and regions including the United States, Germany, South Korea, Malaysia, the United Arab Emirates, and Singapore, earning long-term trust from international customers.