When a mechanical seal fails, the first question is almost always the same:

Is this a pump problem, or is it a seal problem?

In many industrial environments, seal failures quickly turn into disputes between maintenance teams, pump suppliers, and seal manufacturers. However, asking this question in isolation often leads to the wrong conclusion.

The reality is more nuanced. Mechanical seal failure is rarely caused by a single factor, and assigning blame without proper analysis usually results in repeated failures.

Why This Question Is Often Asked the Wrong Way

Mechanical seals operate at the intersection of multiple systems. They are not standalone components, nor are they independent of the pump.

When a seal leaks or fails, it is tempting to look for a simple answer:

-

If the seal failed, blame the seal.

-

If the pump vibrates, blame the pump.

In practice, mechanical seal performance reflects the condition of the entire pump system, not just the seal or the pump alone.

When Mechanical Seal Failure Is Truly a Seal Problem

There are situations where the seal itself is the primary cause of failure, although these cases are less common than many assume.

Incorrect Seal Selection

A seal that is not designed for the actual operating pressure, temperature, or fluid properties will fail regardless of pump condition. Selection errors often occur when real operating conditions differ from nameplate data.

Material Incompatibility

Elastomers, face materials, or secondary sealing elements may degrade if they are incompatible with the pumped fluid or cleaning media. Chemical attack can cause swelling, cracking, or loss of sealing force.

Manufacturing or Assembly Defects

Although rare, defects such as improper face flatness, spring issues, or assembly errors can lead to early failure. These cases typically show clear, localized damage patterns.

In these scenarios, the seal itself is the primary contributor—but confirmation requires physical inspection and failure analysis.

When Mechanical Seal Failure Is a Pump or System Problem

In most real-world cases, seal failure is driven by conditions created by the pump or the system surrounding it.

Shaft Misalignment and Vibration

Misalignment, worn bearings, or imbalance introduce vibration that mechanical seals are not designed to tolerate continuously. Excessive movement accelerates face wear and causes leakage.

Dry Running and Poor Lubrication

Inadequate fluid supply at the seal faces—often during startup or transient operation—leads to rapid overheating and face damage. Dry running is one of the fastest ways to destroy an otherwise suitable seal.

Unstable Operating Conditions

Pressure spikes, temperature cycling, cavitation, and flow instability impose stresses far beyond steady-state design assumptions. These transient conditions are frequently overlooked during troubleshooting.

In such cases, replacing the seal without addressing the underlying system issue almost guarantees repeat failure.

Why Mechanical Seal Failure Is Usually a System-Level Issue

The most accurate answer to the original question is often:

Mechanical seal failure is a system problem, not a pump problem or a seal problem alone.

The seal is a sensitive indicator of system health. When it fails, it is often reacting to:

-

Mechanical instability

-

Thermal stress

-

Inadequate lubrication

-

Improper installation

-

Incomplete application data

Focusing on only one component ignores the interactions that ultimately determine seal performance.

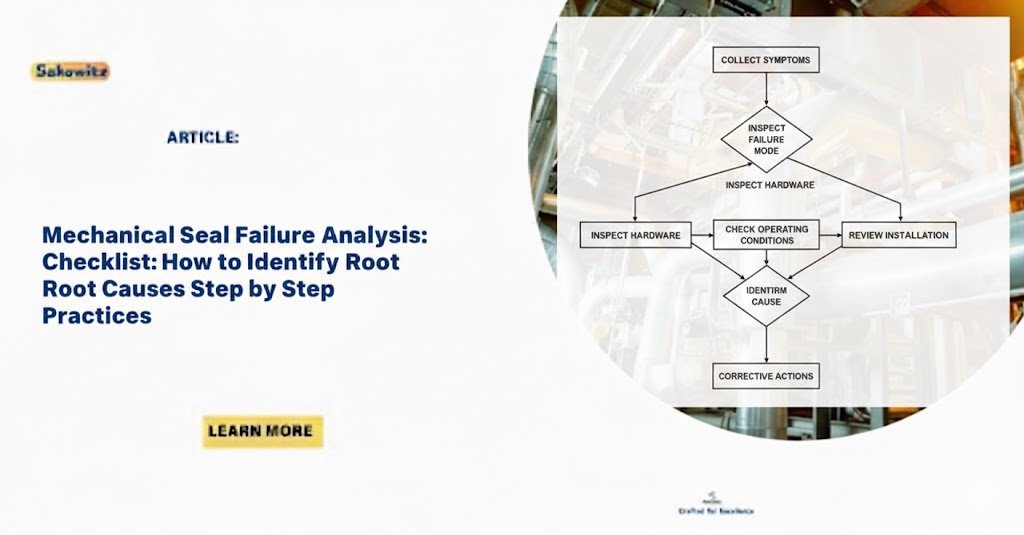

How to Determine the Real Cause of Mechanical Seal Failure

Effective troubleshooting begins with removing assumptions and examining evidence.

Key steps include:

-

Reviewing operating history and recent changes

-

Inspecting wear patterns on seal faces and components

-

Checking shaft alignment, bearing condition, and vibration levels

-

Evaluating startup and shutdown procedures

-

Confirming actual operating conditions versus design assumptions

Only by combining seal inspection with system analysis can the true root cause be identified.

Why Replacing the Seal Alone Often Leads to Repeat Failure

One of the most common mistakes in maintenance practice is treating seal replacement as a corrective action rather than a diagnostic opportunity.

If the conditions that caused the original failure remain unchanged, the new seal will experience the same stresses—and fail in the same way.

This cycle increases downtime, maintenance costs, and frustration without solving the underlying problem.

Final Thoughts: Stop Asking Who Is at Fault, Start Asking Why

Mechanical seal failure should not be viewed as a blame exercise between pump and seal. Instead, it should be treated as a signal that something in the system requires attention.

Understanding whether the root cause lies in seal selection, pump condition, operating practices, or installation quality leads to more reliable solutions and longer seal service life.

In most cases, the question is not whether the failure is a pump problem or a seal problem—but what system condition caused the seal to fail.

👉https://sakowit.com/mechanical-seal-installation-guide-best-practices-to-prevent-early-failure/