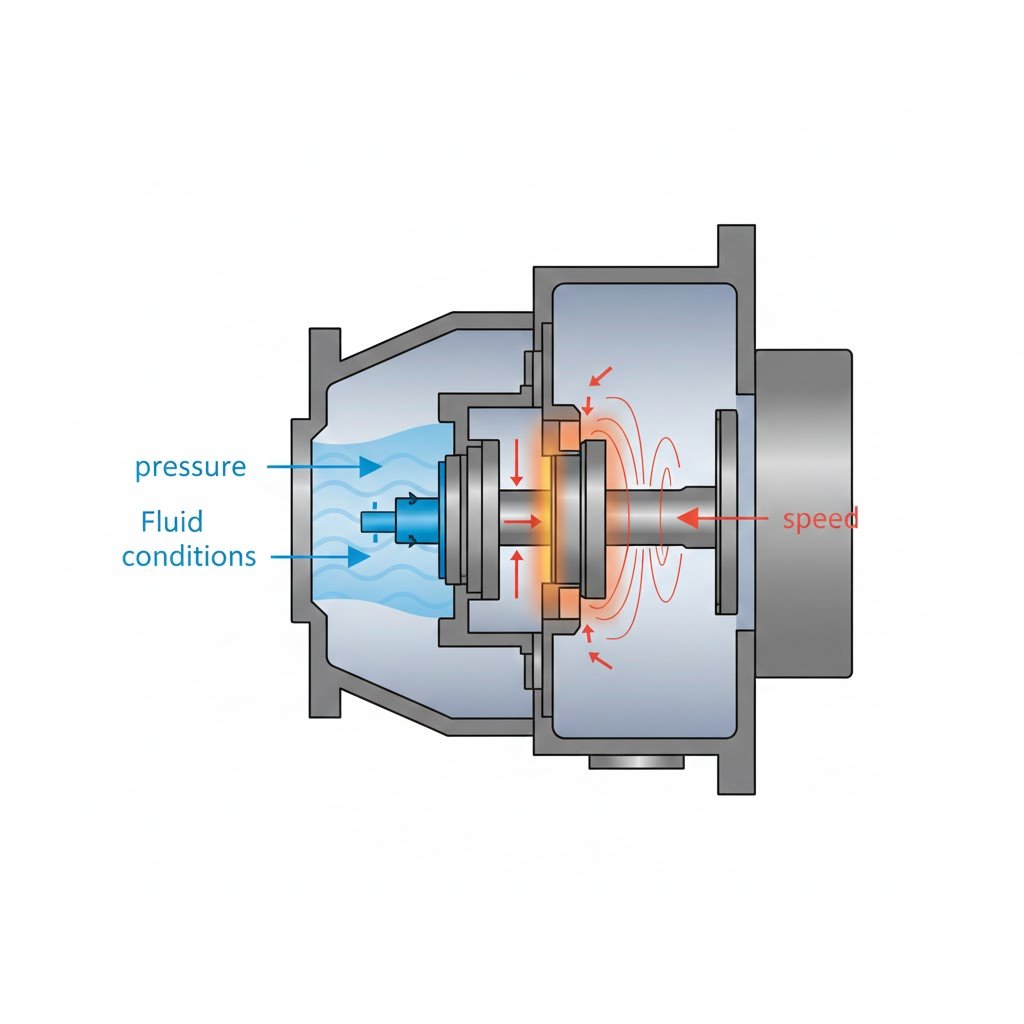

Mechanical seal performance is not determined by seal design alone. In industrial pumps, operating conditions play a decisive role in how long a mechanical seal lasts and how reliably it performs.

Even a well-designed seal can fail prematurely if it operates outside its intended conditions. This article explains how key operating factors affect mechanical seal performance and what pump operators should evaluate to avoid early failures.

1. Pressure and Its Impact on Seal Faces

Operating pressure directly affects the load on mechanical seal faces. As pressure increases, the contact force between the rotating and stationary faces also increases.

Excessive pressure can lead to:

-

Increased face wear

-

Higher frictional heat

-

Distortion of seal faces

-

Breakdown of the lubricating fluid film

Proper pressure balancing and seal selection are critical in high-pressure pump applications.

2. Temperature: The Silent Seal Killer

Temperature has a significant influence on both seal materials and lubrication.

High operating temperatures may cause:

-

-

Elastomer hardening or shrinkage

-

-

Loss of seal face flatness

-

Thermal cracking of carbon faces

-

Accelerated oxidation of sealing fluids

Conversely, extremely low temperatures can reduce elastomer flexibility and lead to leakage during startup.

3. Pump Speed (RPM) and Surface Velocity

Higher pump speeds increase the surface velocity at the seal faces. This generates more frictional heat and places greater demand on cooling and lubrication.

High RPM conditions often require:

-

Advanced seal face materials (SiC, TC)

-

Improved heat dissipation

-

Stable lubrication systems

Ignoring speed-related effects is a common cause of mechanical seal overheating.

4. Process Fluid Characteristics

The process fluid being pumped has a direct impact on seal life.

Key fluid properties to consider include:

-

Lubricity

-

Viscosity

-

Chemical compatibility

-

Presence of solids or abrasives

Poor lubricating fluids or abrasive media can rapidly damage seal faces, even under moderate pressure and temperature.

5. Vibration and Shaft Movement

Mechanical seals are sensitive to vibration and shaft movement. Excessive vibration disrupts face alignment and accelerates wear.

Common vibration sources include:

-

Cavitation

-

Bearing wear

-

Misalignment

-

Hydraulic instability

Controlling vibration is often more effective than upgrading seal materials alone.

6. Start-Stop Cycles and Thermal Shock

Frequent start-stop operations subject mechanical seals to repeated thermal expansion and contraction.

This can result in:

-

Loss of face flatness

-

Elastomer fatigue

-

Increased leakage risk

Seals operating under frequent cycling conditions require robust designs and carefully selected materials.

7. The Interaction of Operating Conditions

Operating conditions rarely act alone. Pressure, temperature, speed, and fluid properties interact with each other.

For example:

-

High temperature combined with poor lubrication greatly increases failure risk

-

High speed combined with vibration accelerates face wear

Understanding these interactions is essential for accurate seal selection.

8. How to Evaluate Operating Conditions Before Seal Selection

Before selecting or replacing a mechanical seal, operators should evaluate:

-

Normal and maximum operating pressure

-

Continuous and peak temperatures

-

Pump speed and duty cycle

-

Process fluid composition

-

Environmental and installation conditions

A comprehensive evaluation prevents misapplication and repeated failures.

Conclusão

Mechanical seal performance in industrial pumps is strongly influenced by operating conditions. Many seal failures attributed to “poor quality” are actually the result of mismatched pressure, temperature, speed, or fluid characteristics.

By understanding how operating conditions affect seal behavior, pump users can make better decisions, extend seal life, and reduce unplanned downtime.

👉https://sakowit.com/cartridge-mechanical-seals-manufacturer/