Mechanical seals are critical components in industrial pumps, yet one of the most common questions asked by maintenance teams, engineers, and procurement managers is:

How long should a mechanical seal actually last?

The answer is not as straightforward as many expect. Unlike bearings or filters, mechanical seals do not have a fixed or guaranteed service life. Their lifespan can range from a few months to several years, depending on how they are selected, installed, and operated.

Understanding what truly determines mechanical seal service life is essential for reducing downtime, avoiding repeated failures, and improving overall pump reliability.

There Is No “Standard” Mechanical Seal Service Life

One of the biggest misconceptions in pump maintenance is the idea that a mechanical seal has a standard or predictable lifespan.

In reality, mechanical seals are system-dependent components. Two identical seals installed in different pumps—or even the same pump under different conditions—can experience dramatically different service lives.

A seal that fails early is not necessarily defective. In many cases, premature failure is a symptom of system-level issues rather than a product-quality problem.

Typical Mechanical Seal Lifespan Under Ideal Conditions

While there is no universal lifespan, it is still useful to understand what is reasonable under stable operating conditions.

Clean Water and Light-Duty Applications

In clean water services with stable temperatures, moderate pressures, and proper shaft alignment, mechanical seals can often operate reliably for one to three years or longer.

These applications place minimal stress on sealing faces and elastomers, allowing the seal to function close to its design intent.

Chemical and Process Industry Applications

In chemical processing, pharmaceutical production, or other demanding environments, seal life becomes far more variable.

Factors such as corrosive fluids, temperature fluctuations, pressure changes, and solids contamination can significantly shorten service life. In these cases, seal longevity depends heavily on how well operating conditions are controlled rather than the seal type alone.

It is common for seals in harsh process applications to experience reduced lifespan if system conditions are underestimated during selection.

Key Factors That Determine Mechanical Seal Service Life

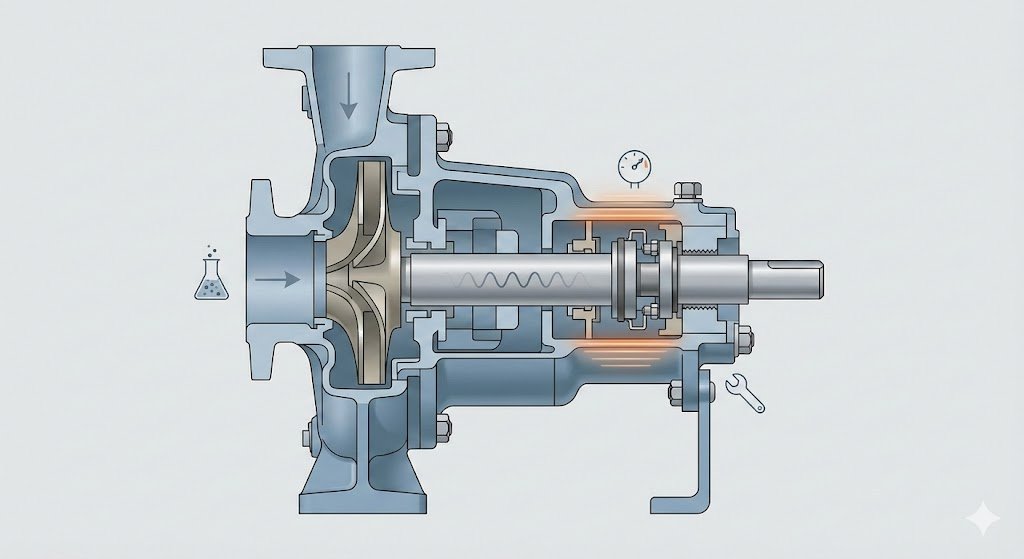

The service life of a mechanical seal is primarily determined by how the entire pump system operates. The most influential factors include the following.

Operating Pressure and Temperature

High pressure and elevated temperatures increase thermal stress on seal faces and secondary sealing elements. Even more damaging than sustained high temperature are rapid temperature changes, which can cause distortion, face separation, or elastomer degradation.

Transient operating conditions are often overlooked during seal selection, yet they play a major role in premature failure.

Shaft Alignment and Vibration

Poor shaft alignment, excessive runout, or vibration caused by worn bearings can quickly damage sealing faces. Mechanical seals are designed to tolerate limited movement, but continuous vibration accelerates face wear and reduces sealing stability.

Many seal failures attributed to “seal quality” are ultimately traced back to mechanical issues within the pump or driver.

Fluid Properties

The pumped fluid itself has a direct impact on seal performance. Solids, crystallization, inadequate lubricity, or chemical incompatibility can all shorten seal life.

A fluid that appears harmless under normal conditions may become highly aggressive when temperature, concentration, or flow rate changes.

Start-Stop Frequency

Frequent pump start-stop cycles expose seals to repeated dry-running conditions during startup. This brief but critical phase can cause face damage if not properly managed.

Applications with frequent cycling require special attention during seal selection and system design.

Installation Quality

Even the best mechanical seal can fail prematurely if installed incorrectly. Small deviations in installation procedures—such as improper setting length, contamination, or uneven tightening—can dramatically reduce service life.

Installation quality often determines whether a seal reaches its expected lifespan or fails within weeks.

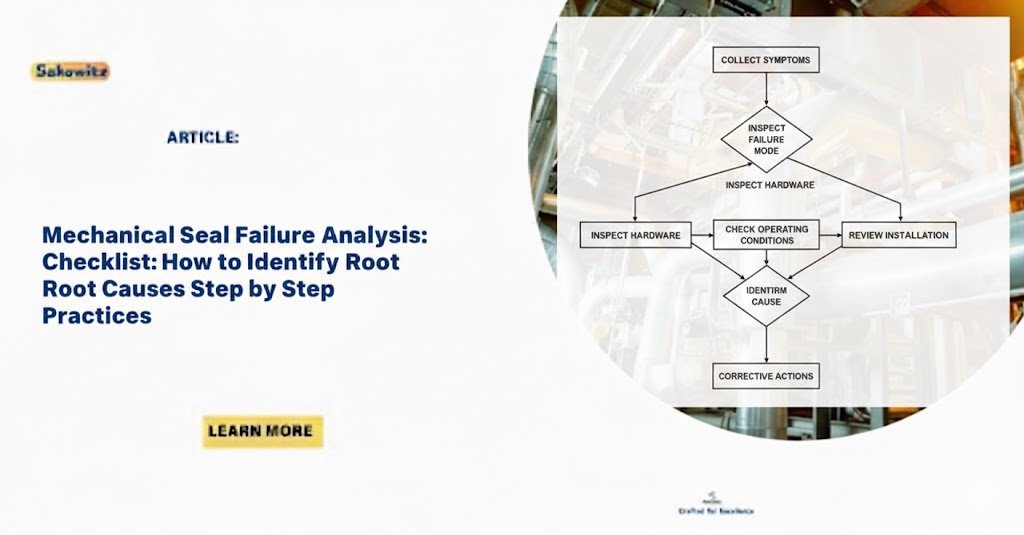

Why Mechanical Seals Often Fail Earlier Than Expected

Many premature seal failures are not caused by the seal itself but by incorrect assumptions made during selection or operation.

Misinterpreting Seal Failure as a Product Defect

When a seal fails early, it is easy to assume a manufacturing issue. However, without analyzing operating conditions, this conclusion can be misleading and lead to repeated failures.

Ignoring System-Level Problems

Issues such as cavitation, dry running, or unstable suction conditions frequently damage seals indirectly. Unless these root causes are addressed, replacing the seal alone will not solve the problem.

Incomplete Operating Data During Selection

Seal selection based only on pump nameplate data often overlooks real-world conditions. Missing information—such as startup behavior, cleaning cycles, or fluid variations—can result in an unsuitable seal choice.

How to Extend Mechanical Seal Service Life in Real Applications

While no seal lasts forever, there are practical steps that significantly improve reliability and lifespan.

Provide Complete and Accurate Operating Data

Sharing detailed operating conditions—including temperature ranges, pressure fluctuations, fluid composition, and startup behavior—allows for more appropriate seal selection and reduces unexpected failures.

Improve Installation and Maintenance Practices

Proper installation procedures, cleanliness, and post-installation checks are essential. Routine monitoring of vibration, alignment, and bearing condition helps prevent secondary damage to the seal.

Match Seal Design to Actual Conditions

Selecting a seal based on real operating conditions—not idealized assumptions—ensures the seal can handle the stresses it will encounter in service.

Working with experienced seal specialists can help identify risks before failure occurs.

Final Thoughts: Seal Life Is a System Result, Not a Single Component Issue

Mechanical seal service life is not determined by the seal alone. It is the result of pump design, operating conditions, installation quality, and maintenance practices working together.

Understanding this broader perspective helps reduce downtime, lower maintenance costs, and improve overall pump reliability. Instead of asking how long a seal should last, the better question is whether the system allows the seal to operate as designed.

👉https://sakowit.com/how-to-replace-oem-mechanical-seals-without-changing-pump-design/

👉https://sakowit.com/how-to-identify-the-root-cause-of-mechanical-seal-leakage-in-industrial-pumps/