Introduction: Why Mechanical Seal Maintenance Matters More Than You Think

Mechanical seals are precision components, but they operate in imperfect real-world conditions.

Many premature seal failures are not caused by poor seal design, but by improper inspection, incorrect start-up procedures, or rushed shutdowns.

A structured maintenance checklist helps:

-

Prevent dry running

-

Avoid thermal shock

-

Reduce leakage incidents

-

Extend seal service life

This article provides a practical mechanical seal maintenance checklist, covering inspection, start-up, and shutdown best practices used in reliable pump operations.

Pre-Installation & Routine Inspection Checklist

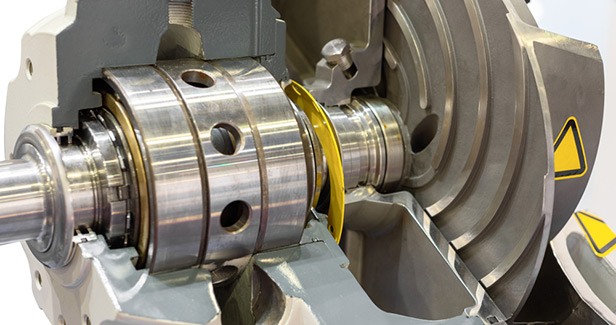

1️⃣ Seal Condition Inspection

-

Check seal faces for scratches or chips

-

Inspect elastomers for cracks or hardening

-

Verify springs or bellows move freely

-

Ensure no contamination on seal faces

2️⃣ Shaft and Seal Chamber Inspection

-

Measure shaft runout and straightness

-

Check shaft sleeve surface finish

-

Inspect seal chamber for corrosion or debris

-

Confirm seal chamber dimensions match the seal

3️⃣ Support System Verification

-

Confirm flush lines are clean and unobstructed

-

Verify correct API flush plan configuration

-

Check barrier or buffer fluid level and pressure

-

Ensure cooling systems are operational

A clean and stable environment is the foundation of seal reliability.

Mechanical Seal Start-Up Best Practices

Start-up is one of the highest-risk moments for mechanical seals.

Start-Up Checklist

-

Ensure the pump is fully primed

-

Open suction and discharge valves properly

-

Verify flush or barrier fluid flow

-

Confirm seal chamber temperature is within limits

-

Start the pump gradually where possible

Common Start-Up Mistakes

-

Starting the pump without priming

-

Ignoring flush flow during startup

-

Rapid acceleration causing thermal shock

Even a few seconds of dry running during startup can permanently damage seal faces.

Mechanical Seal Shutdown Best Practices

Shutdown procedures are just as important as start-up.

Shutdown Checklist

-

Reduce pump speed gradually if possible

-

Maintain flush flow during initial shutdown

-

Avoid sudden temperature changes

-

Allow the seal to cool before stopping auxiliary systems

Common Shutdown Errors

-

Stopping flush systems too early

-

Rapid shutdown under high temperature

-

Ignoring seal chamber cooling time

Improper shutdown often leads to thermal cracking or face distortion.

Ongoing Operational Monitoring Checklist

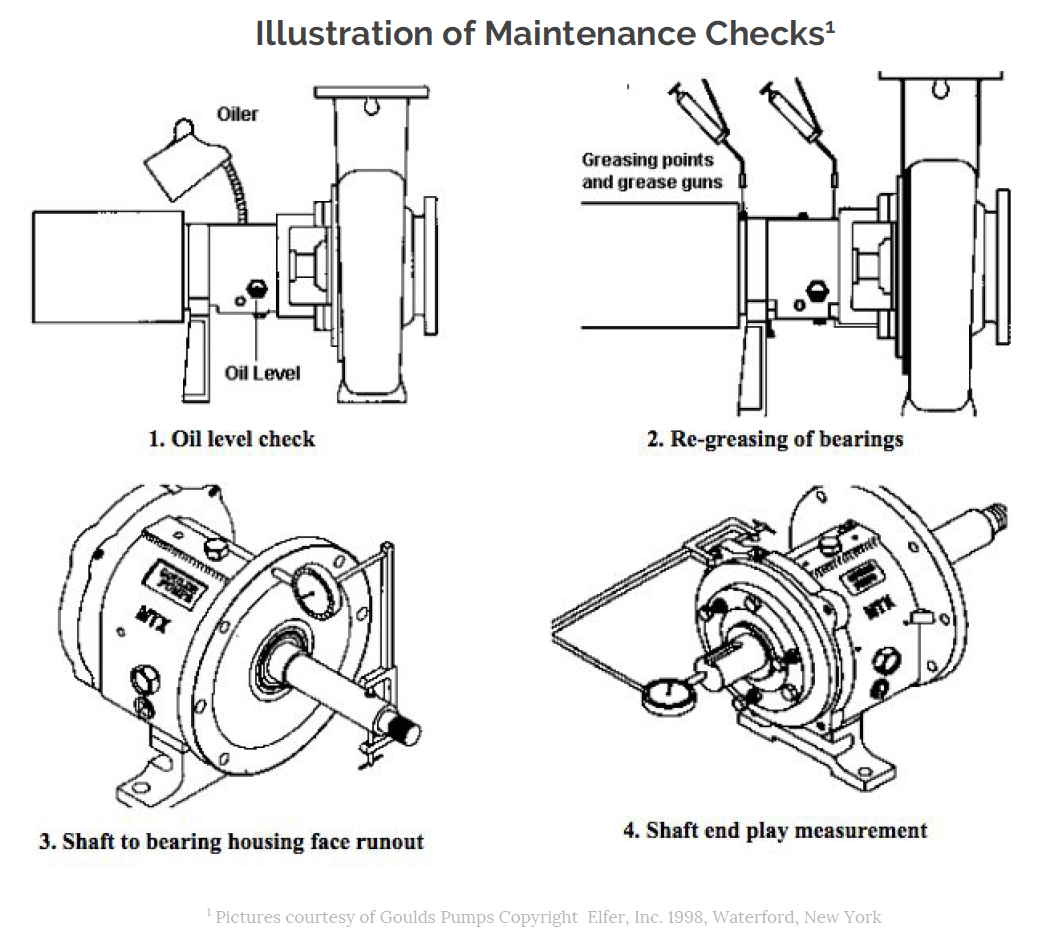

Daily or Shift-Based Checks

-

Monitor leakage rate and pattern

-

Check seal chamber temperature

-

Listen for abnormal noise or vibration

-

Observe barrier or buffer fluid condition

Periodic Maintenance Checks

-

Inspect flush flow and pressure

-

Check alignment and coupling condition

-

Review vibration trends

-

Replace worn components proactively

Special Considerations for Challenging Applications

For slurry, abrasive, or high-temperature services:

-

Increase inspection frequency

-

Monitor wear indicators closely

-

Verify flush cleanliness and pressure

-

Consider double seals or upgraded materials

In harsh applications, maintenance discipline directly determines seal life.

Common Mechanical Seal Maintenance Mistakes

-

Treating seals as “install and forget” components

-

Skipping alignment verification

-

Ignoring early leakage signs

-

Using incorrect flush fluids

-

Inconsistent startup and shutdown practices

These mistakes account for a large percentage of repeat seal failures.

FAQ: Mechanical Seal Maintenance

Q1: How often should mechanical seals be inspected?

Visual and operational checks should be done regularly, with detailed inspections during scheduled maintenance.

Q2: Is leakage always a sign of seal failure?

Not always. Controlled leakage may be normal, but sudden or increasing leakage requires investigation.

Q3: Can better materials eliminate maintenance needs?

No. Even the best materials require proper maintenance and operating practices.

Final Thoughts: Maintenance Is a Reliability Strategy

Mechanical seal reliability is not achieved by component selection alone.

It depends on consistent inspection, disciplined startup, controlled shutdown, and continuous monitoring.

A simple checklist—applied consistently—can prevent most avoidable seal failures.

Call to Action (CTA)

👉 Need help improving mechanical seal reliability in your plant?

Share your pump type, operating conditions, and maintenance challenges. Our technical team can help optimize seal selection, support systems, and maintenance practices.