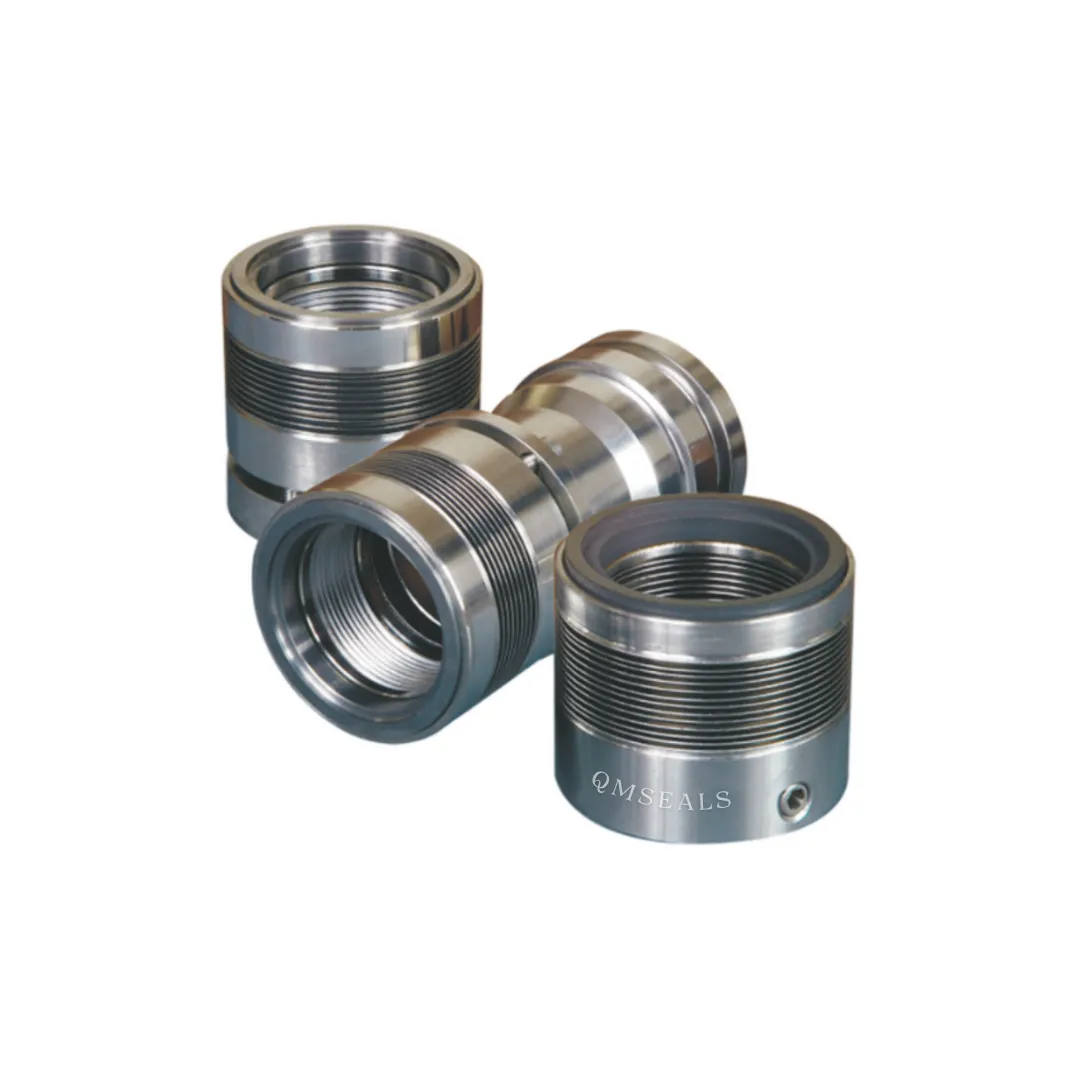

Metal Bellow Seal Manufacturer

– Ensuring safe, leak-free operation of equipment under extreme conditions.

Sakowitz is dedicated to providing reliable sealing solutions for pumps, compressors, and reactors operating under high-temperature and corrosive conditions.

Structure and Function of Metal Bellow Seals

Metal bellows mechanical seals are high-performance sealing components used in pumps, compressors, reactors, and similar equipment. They replace traditional springs with metal bellows to achieve axial compensation and dynamic sealing without relying on rubber components, thereby offering superior high-temperature resistance and chemical corrosion resistance. This design effectively prevents liquid or gas leakage, making it particularly suitable for extreme conditions with temperatures up to 400°C and pressures as high as 60 bar.

Metal bellows seals are widely adopted in petrochemical, pharmaceutical, energy, and vacuum systems, serving as the preferred solution for high-reliability sealing applications.

Why Choose Metal Bellow Seals

Metal bellows seals demonstrate exceptional stability and sealing performance under high-temperature, high-pressure, and highly corrosive conditions. Their elastic-free design effectively avoids issues such as rubber aging, thermal decomposition, or chemical swelling, making them suitable for operating temperatures up to 400°C.

The bellows’ self-compensating properties absorb axial displacement and end-face wear, extending equipment lifespan and reducing maintenance costs. Additionally, the use of corrosion-resistant alloys such as Hastelloy®, Inconel®, and SS316 ensures outstanding sealing performance even in acidic, alkaline, and organic solvent environments. These seals are widely employed in continuous-operation equipment within the chemical, petrochemical, and energy industries, making them an ideal choice for high-reliability, zero-leakage systems.

Metal Bellow Seal Product Series

Entre em contato com nossos especialistas em selos mecânicos para tirar dúvidas

Entre em contato conosco e nossa equipe profissional da Sakowit poderá ajudá-lo a encontrar o selo mecânico mais adequado para aumentar a segurança do seu projeto.

Sakowitz Engineering – Precision Metal Bellow Seal Solutions

Sakowitz brings over 30 years of sealing design and manufacturing expertise, specializing in reliable Metal Bellow Seal solutions for high-temperature, high-pressure, and corrosive applications. Our compact, easy-to-install seals are widely used in centrifugal pumps, vacuum pumps, compressors, and stirred reactors.

- Multiple configurations: Single-ended, double-ended, balanced, and unbalanced designs to meet diverse system requirements.

- High-performance bellows materials: Utilizing Hastelloy®, Inconel®, AM350, SS316 for exceptional thermal expansion resistance and corrosion resistance.

- Premium friction pair materials: Moving and stationary rings utilize SiC / WC / Carbono for low wear and extended service life.

- Stringent standard certifications: Designed to comply with API 682, ISO 21049, CE, ATEX international industrial specifications.

- Engineering-grade compatibility: Direct replacement for seals in major pump brands, enabling zero-error installation.

Technical Overview of Sakowitz Metal Bellow Seals

Sakowitz metal bellows seals are specifically engineered for high-temperature, high-pressure, and highly corrosive environments, delivering exceptional durability and sealing precision. All products are certified to API 682 and ISO 21049 international standards and are widely used in pump, compressor, and reactor systems.

| Parâmetro | Especificação / Faixa |

|---|---|

| Pressão | Up to 60 bar – Suitable for high-pressure industrial systems. |

| Temperatura | -40°C ~ +400°C – Reliable under extreme thermal conditions. |

| Velocidade | Up to 50 m/s – Designed for high-speed rotating shafts. |

| Bellow Materials | Hastelloy® / Inconel® / SS316 / AM350 – Excellent flexibility and corrosion resistance. |

| Materiais para a face | SiC / WC / Carbon – Superior wear resistance and heat stability. |

| Metais | SS316 / Duplex / Hastelloy® – High strength with excellent corrosion protection. |

| Padrões | API 682 / ISO 21049 / CE / ATEX – Fully compliant with global industrial standards. |

| Aplicativos | Pumps, Compressors, Reactors, Agitators – Ideal for chemical, petrochemical, and energy sectors. |

Industries & Applications of Metal Bellow Seals

Sakowitz metal bellows seals are widely used across multiple critical industrial sectors due to their exceptional resistance to high temperatures and corrosion, coupled with zero leakage performance. Their design meets the demands of continuous operation and harsh environments.

It is suitable for corrosive media such as strong acids, strong alkalis and organic solvents, ensuring the safety and cleanliness of the chemical process.

It performs stably in high-temperature and high-pressure underground systems and can effectively prevent medium leakage and energy loss.

Meet the requirements of aseptic and vacuum environments to ensure process purity and system safety.

Widely used in steam turbines, cooling systems and boiler circulating pumps to enhance the operational efficiency of equipment.

The corrosion-resistant structure can be exposed to seawater for a long time and maintain reliable sealing performance.

It offers a hygienic, oil-free design that meets the strict standards of food and bioprocesses.

Why Choose Sakowitz as Your Metal Bellow Seal Partner

As a manufacturer with over three decades of experience in sealing technology, Sakowitz provides high-performance Metal Bellow Seal solutions to customers worldwide.

Our products are renowned for their precise manufacturing, high reliability and outstanding corrosion resistance, and have been verified in key industrial systems in over 50 countries.

- Experiência rica: Focused on mechanical seal design and manufacturing for over 30 years, with deep expertise in the chemical, energy, and pharmaceutical industries.

- Confiança global: With over 20,000+ successful installation cases, our customers are spread across Europe, Asia, and the Middle East.

- Precision Manufacturing: Utilizing high-precision CNC processes, achieving end face flatness <2 µm, ensuring zero leakage operation.

- Customized Solutions: Offering OEM alternatives and custom designs for special operating conditions, balancing performance and cost-effectiveness.

- Premium Materials: Selecting high-temperature and corrosion-resistant alloys such as Hastelloy® and Inconel® to extend seal life.

- Technical Support: Providing global engineering services, installation guidance, and after-sales consultation.

Sakowitz – Defining the industry standard for metal bellows mechanical seals with precision engineering and global trust.

FAQ – Common Questions About Metal Bellow Seals

Q1: Can Sakowitz metal bellow seals replace OEM models?

Yes. Sakowitz offers OEM-compatible design and customized engineering solutions that can be directly installed without modifying the equipment structure.

Q2: Qual é a vida útil típica?

It is usually 3 to 5 years, depending on the working temperature, medium characteristics and maintenance frequency. Under correct installation and normal operating conditions, its service life can be significantly longer than that of traditional sealing structures.

Q3: Are these seals suitable for high-temperature acids or solvents?

Completely applicable. Sakowitz offers Hastelloy and Inconel Made of high-performance alloy materials, it can maintain stable sealing in highly corrosive and high-temperature environments.

Q4: Do you provide API-compliant designs?

Yes. All models comply with API 682 and ISO 21049 industrial sealing standards to ensure engineering reliability and safety.

Envie uma cotação rápida

Por que temos a confiança de mais de 1.000 clientes

Excelência em engenharia - Precisão que funciona

Cada vedação da Sakowit é projetada, usinada e testada para proporcionar máxima confiabilidade e longa vida útil, mesmo nos ambientes mais difíceis.

Desempenho comprovado - confiável em todos os setores

Com a confiança de engenheiros de todo o mundo para um desempenho consistente em sistemas de processos químicos, de polpas abrasivas e de alta demanda.

Suporte global - Resposta rápida, serviço confiável

A rede global e o suporte ágil garantem que você receba ajuda especializada quando precisar, onde quer que esteja.