A Practical SEO Selection Guide

Introduction: Why Mechanical Seal Selection Matters

Selecting the right mechanical seal for your pump application is not just a technical decision — it directly affects equipment reliability, maintenance cost, downtime, and safety. An incorrect seal choice can lead to premature leakage, excessive wear, product contamination, or even catastrophic pump failure.

This practical guide explains how to choose the right mechanical seal step by step, based on real operating conditions rather than generic catalog descriptions. Whether you are replacing an OEM seal or designing a new pump system, this guide will help you make a confident, cost-effective decision.

Step 1: Understand Your Pump Application Conditions

Before selecting any mechanical seal, you must clearly define the actual operating conditions. Most seal failures occur because real conditions differ from assumed ones.

Key parameters to confirm:

-

Operating pressure (including pressure spikes)

-

Operating temperature (minimum & maximum)

-

Rotational speed (RPM)

-

Fluid type (clean, dirty, corrosive, abrasive)

-

Presence of solids or crystallization

-

Installation orientation (horizontal or vertical)

Tip: If you cannot fully confirm conditions, always select a seal with higher tolerance margins, not the cheapest option.

Step 2: Choose the Right Seal Structure

Single vs Double Mechanical Seals

-

Single mechanical seals

Suitable for clean, non-hazardous fluids with moderate pressure and temperature. -

Double mechanical seals

Recommended for toxic, flammable, abrasive, or high-temperature applications where leakage must be controlled.

Balanced vs Unbalanced Seals

-

Balanced seals handle higher pressure and temperature with better face stability.

-

Unbalanced seals are simpler and more cost-effective for low-pressure systems.

Bellows Type Selection

-

Rubber bellows seals

Flexible, economical, suitable for water and general industrial fluids. -

Metal bellows seals

Ideal for high temperature, corrosive fluids, and applications where elastomers may fail.

Step 3: Select the Correct Seal Face Materials

Seal face material selection is critical for wear resistance and chemical compatibility.

Common combinations:

| Seal Face Pair | Typical Applications |

|---|---|

| Carbon / Ceramic | Clean water, HVAC, light duty |

| Carbon / Silicon Carbide | Chemical pumps, moderate abrasives |

| Silicon Carbide / Silicon Carbide | Slurry, wastewater, abrasive fluids |

| Tungsten Carbide / Tungsten Carbide | Severe abrasion, high load |

Rule of thumb:

If solids, slurry, or crystallization are present → SiC or TC is strongly recommended.

Step 4: Choose the Right Secondary Sealing Materials

Secondary seals (O-rings, bellows) must withstand both temperature and chemical exposure.

Common elastomer options:

-

NBR (Nitrile) – water, oil, low temperature

-

EPDM – hot water, steam, food applications

-

Viton (FKM) – chemicals, high temperature

-

PTFE – aggressive chemicals, extreme conditions

Incorrect elastomer selection often causes swelling, cracking, or loss of elasticity, leading to leakage even if seal faces are correct.

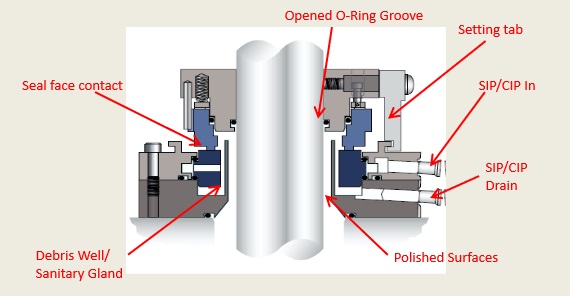

Step 5: Consider Cartridge vs Component Seals

-

Component seals

Lower cost but require precise installation and experienced technicians. -

Cartridge mechanical seals

Pre-assembled, factory-set, and easier to install. They significantly reduce installation errors and downtime.

For most industrial users today, cartridge seals are the preferred choice, especially for critical pumps or frequent maintenance cycles.

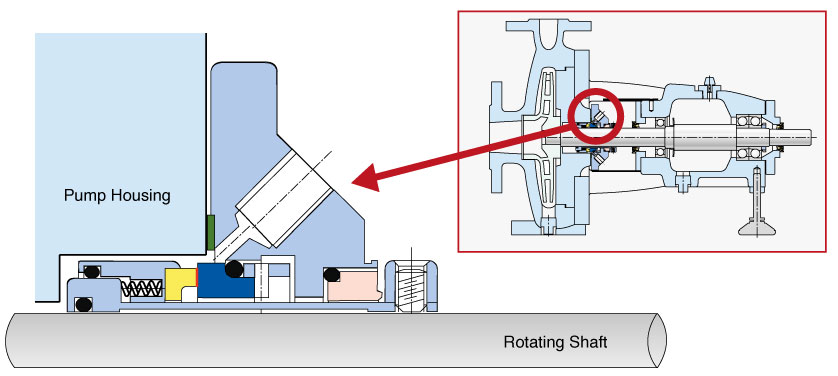

Step 6: Verify Shaft and Seal Chamber Dimensions

Even the best seal will fail if dimensions are incorrect.

Confirm the following:

-

Shaft diameter and tolerance

-

Seal chamber bore and depth

-

Available axial space

-

Flush and cooling ports

Always cross-check drawings or provide photos before final selection — especially for OEM replacement seals.

Common Mechanical Seal Selection Mistakes

-

Choosing seals based on price only

-

Ignoring pressure fluctuations

-

Underestimating solid content in fluid

-

Using standard elastomers in chemical media

-

Replacing OEM seals without dimensional verification

Avoiding these mistakes can extend seal life by 2–3 times.

FAQ: Mechanical Seal Selection

Q1: Can I replace an OEM seal with a non-OEM mechanical seal?

Yes, as long as dimensions, materials, and performance ratings match or exceed OEM specifications.

Q2: Is double seal always better than single seal?

Not always. Double seals add cost and complexity. They are only necessary when leakage control or safety is critical.

Q3: How do I know if my seal is balanced?

Balanced seals are typically specified by manufacturers or indicated in technical drawings. When unsure, consult a seal specialist.

Final Thoughts: Make Selection Based on Reality, Not Assumptions

Mechanical seal selection is not about choosing a model number — it is about matching the seal to real operating conditions. Taking time to evaluate structure, materials, and installation factors will dramatically reduce maintenance costs and unplanned downtime.

If you are unsure about your application, providing photos, drawings, and operating data will always result in a better recommendation than guessing.

Call to Action (CTA)

👉 Need help selecting or replacing a mechanical seal for your pump?

Contact our engineering team with your pump model, application conditions, or photos — we provide OEM-compatible and custom mechanical seal solutions tailored to your needs.

👉https://sakowit.com/is-mechanical-seal-failure-a-pump-problem-or-a-seal-problem/