Keywords: mechanical seal failure, seal troubleshooting

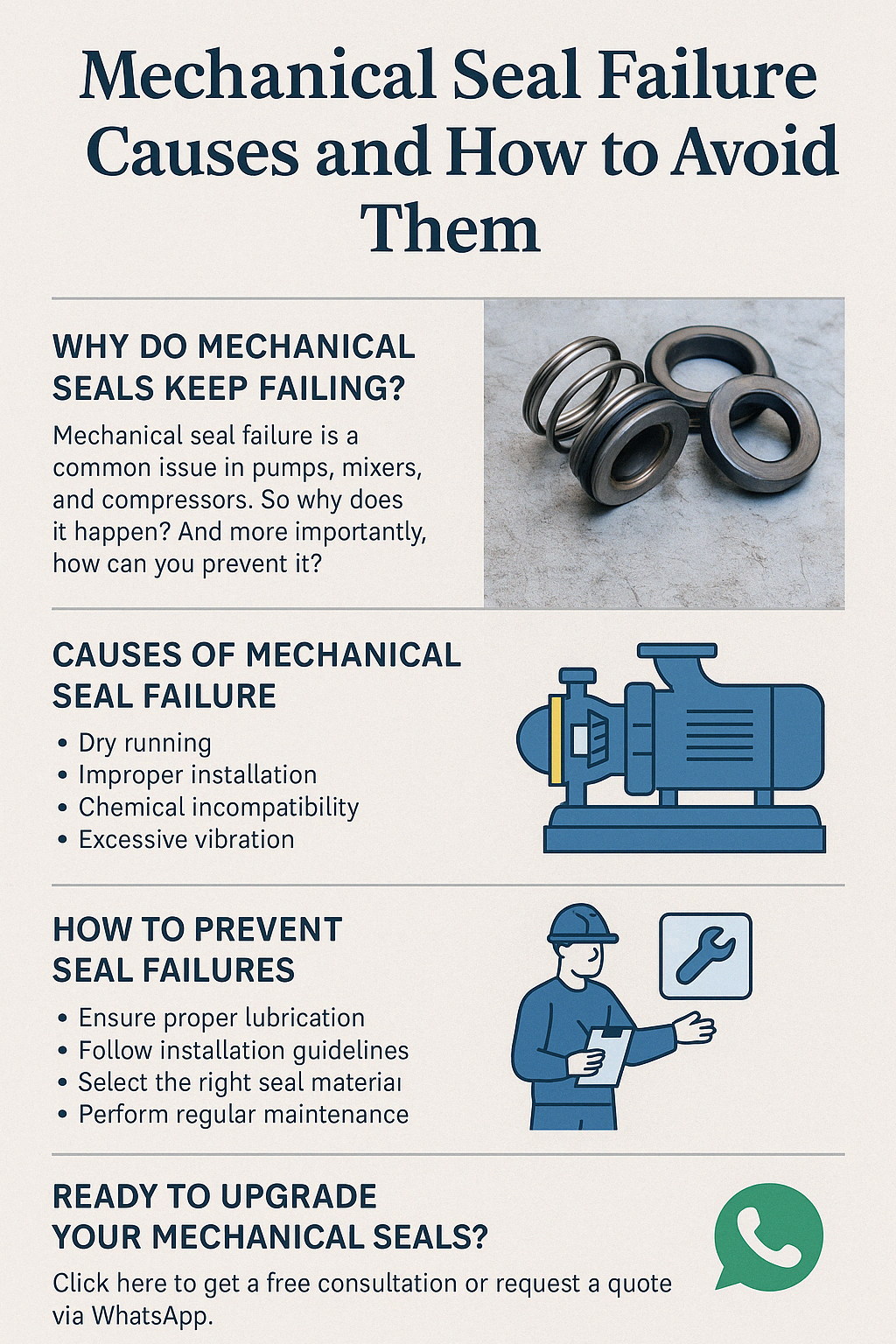

Why Do Mechanical Seals Keep Failing?

Mechanical seal failure is one of the most common—and costly—reliability issues in rotating equipment like pumps, mixers, and compressors. Whether you’re working in a chemical plant, water treatment facility, or food processing line, a leaking seal can mean equipment downtime, product loss, and safety risks.

So why does it happen? And more importantly, how can you prevent it?

In this article, we’ll walk you through the main causes of mechanical seal failure and offer practical troubleshooting and prevention strategies. Whether you’re an engineer, maintenance manager, or industrial buyer, this guide will help you save time, cost, and headaches.

Top 6 Causes of Mechanical Seal Failure

1. Dry Running

When a seal operates without lubrication from the pumped fluid, friction and heat quickly destroy the seal faces.

Seal troubleshooting tip: Always check that your pump is primed and the fluid is present before startup.

2. Improper Installation

Misalignment, over-tightening, or contamination during installation can lead to premature failure.

Prevention: Use experienced technicians and always follow manufacturer guidelines. Refer to our installation guide for tips.

3. Chemical Incompatibility

Using the wrong seal material for the fluid can cause corrosion, swelling, or rapid wear.

Solution: Match seal materials (like Viton, PTFE, or Silicon Carbide) to the chemical properties of your medium.

4. Excessive Vibration

Pump imbalance or misalignment increases stress on the seal and shortens lifespan.

Troubleshooting: Monitor vibration levels and check coupling alignment regularly

5. Incorrect Seal Type

Using a single spring seal where a cartridge seal is required can lead to failure under pressure or speed.

Advice: Use cartridge mechanical seals for aggressive media or high-speed environments. Explore models like M481K here.

6. Poor Maintenance

Lack of routine inspections, seal face cleaning, or O-ring replacement accelerates failure.

Best practice: Implement a preventive maintenance schedule with proper documentation.

✅ How to Prevent Seal Failures

| Problem | Prevention Strategy |

| Dry Running | Install flow sensors or dry-run protection |

| Chemical attack | Choose seals with correct material compatibility |

| Incorrect installation | Provide installer training + follow certified procedures |

| Excessive pressure/vibration | Install pressure relief + align shafts |

| Inadequate seal type | Select suitable seal based on speed, fluid, and pressure |

| Maintenance neglect | Schedule periodic checks and replace worn parts early |

FAQ: Mechanical Seal Troubleshooting

Q1: How do I know if my mechanical seal is failing?

A: Common signs include visible leakage, unusual vibration, or rapid pressure drop in your pump.

Q2: How long should a mechanical seal last?

A: It depends on the application, but quality mechanical seals typically last 1–3 years with proper use.

Q3: Can I replace only the seal faces?

A: In many cases, yes. But for critical applications, a full assembly replacement is recommended.

Q4: What’s the best seal for aggressive chemicals?

A: Cartridge seals with silicon carbide or PTFE materials are usually ideal.

Internal & External Links for SEO

Mechanical Seal Product Landing Page

Cartridge Seal for Reactors – M481K

Ready to Upgrade Your Mechanical Seals?

If you’re experiencing frequent seal failures, it may be time to upgrade to high-performance models.

Click here to get a free consultation or request a quote via WhatsApp

Let Sakowitz help you solve it once and for all.