Keywords: M481K, high-temperature mechanical seal, reactor seal

This article explores how mechanical seals transform industrial efficiency, highlights the industries driving demand, and provides insights into the value they deliver.

Built for Extreme Reactor Conditions

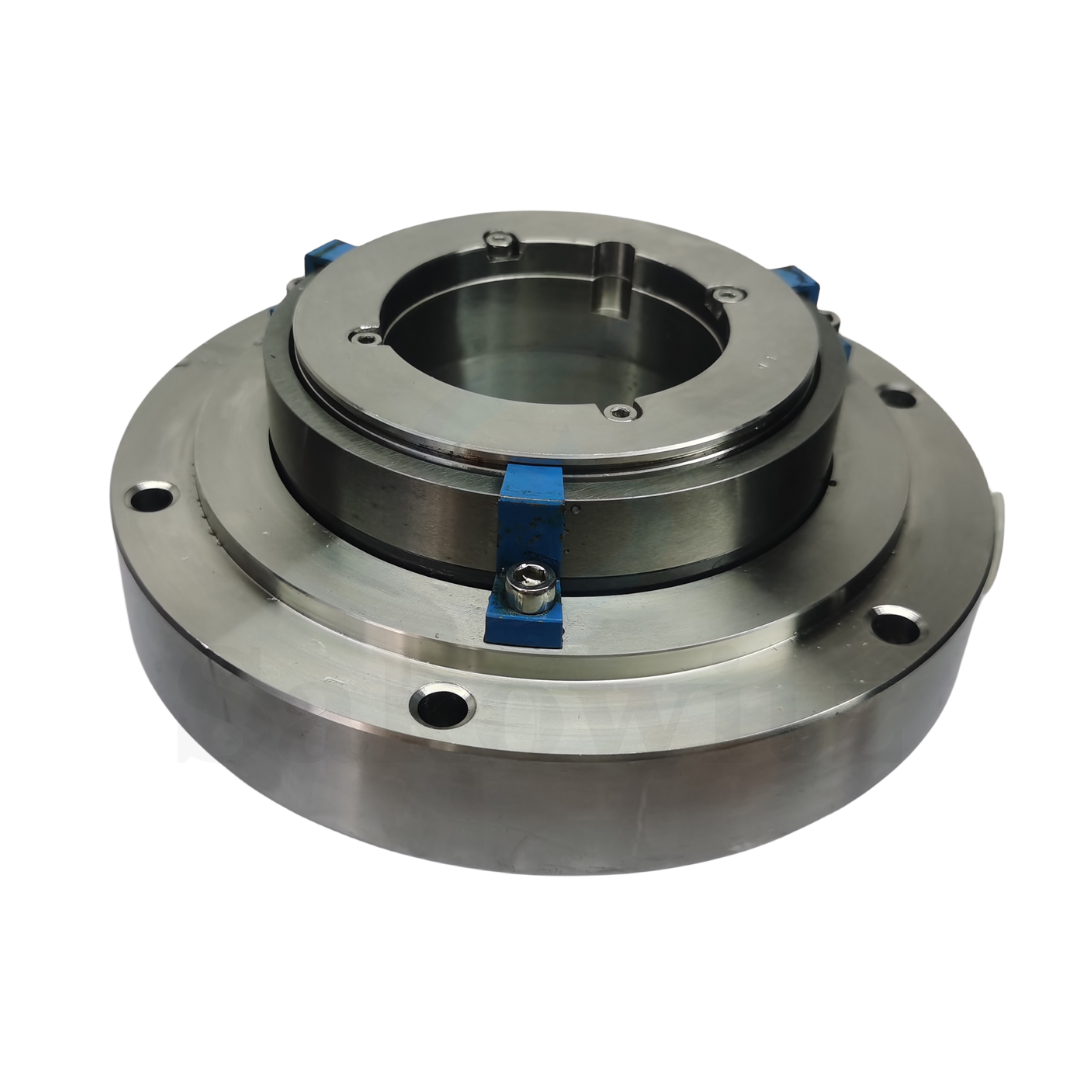

When operating in the high-stakes environment of industrial reactors, the wrong mechanical seal can mean leaks, downtime, and costly shutdowns. That’s why the M481K mechanical seal has become the seal of choice for engineers dealing with high-temperature, high-pressure, and chemically aggressive conditions.

Rather than offering a generic overview, this article focuses on real-world application impact, highlighting the tangible advantages of using M481K in industries such as pharmaceuticals, chemicals, and petrochemicals.

What Makes the M481K Unique?

“A seal designed not just to survive, but to thrive under pressure.”

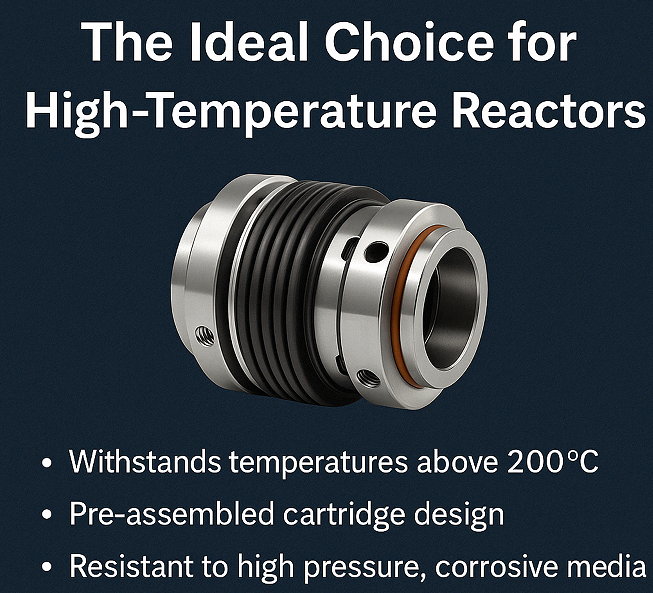

- Temperature Endurance: Withstands sustained temperatures beyond 200°C, making it ideal for heated reactions and steam-intensive environments.

- Cartridge Configuration: Delivered pre-assembled for plug-and-play installation, reducing labor and error risk.

- Pressure Containment: Engineered for internal vessel pressures common in reactor agitation.

Material Versatility: Options for SiC, TC, graphite faces with PTFE or Viton O-rings ensure adaptability to acids, solvents, and steam.

Where M481K Proves Its Value

Rather than tell you it’s “versatile,” here’s where M481K actually thrives:

- Chemical Plants: For high-pressure polymerization and exothermic reactions.

- Pharmaceutical Reactors: Where sterile sealing and CIP compatibility are crucial.

- Energy Sector: In volatile pressurized systems with thermal cycling.

Agitated Vessels: In mixing environments with dual stresses: heat + motion.

Why Engineers Prefer M481K Over Standard Seals

Performance Comparison Snapshot:

- +30–50% longer seal life under continuous high-load duty

- Reduced downtime from premature seal failures

- Lower total cost of ownership over 12–24 months

Many clients report 2–3x seal longevity compared to traditional multi-spring units in reactor applications.

Case Highlight: Specialty Chemical Manufacturer

A leading chemical processor in Gujarat replaced standard pump seals with M481K on 12 reactor vessels. Within 9 months:

- Mechanical seal failures dropped from 8 to 1

- Maintenance time cut by 60%

- Annual seal budget reduced by 40%

“We finally got stability in our reactors. M481K gave us performance we could count on.” — Plant Manager

Buyer Questions Answered

Can M481K handle caustic and acidic blends?

Yes, especially with PTFE elastomers.

How long does it typically last in a reactor?

1.5–3 years depending on runtime and media.

Does it come with installation support?

Yes, manuals and remote tech support are provided.

Useful Resources

Final Word

If your reactor processes demand a mechanical seal that performs without excuses, M481K is your long-term solution. Built for extremes, tested in the field, and backed by Sakowitz expertise.

Get in touch now to discuss sizing, customization, and delivery timelines.