Introduction: Why Slurry Applications Destroy Mechanical Seals Faster

Mechanical seals operating in slurry or abrasive fluids face one of the harshest sealing environments.

Solid particles trapped between seal faces cause rapid abrasive wear, excessive heat generation, and premature leakage.

In many slurry applications, seal failure is not caused by poor manufacturing quality—but by inappropriate seal design and system configuration.

This article explains how slurry and abrasive fluids damage mechanical seals, and provides practical design tips to reduce seal face wear and extend service life.

How Slurry and Abrasive Fluids Damage Seal Faces

Slurry fluids contain solid particles suspended in liquid, such as sand, minerals, catalysts, or process residues.

Primary Damage Mechanisms:

-

Particles enter the seal face interface

-

Abrasive scratching and grooving of seal faces

-

Breakdown of the lubricating fluid film

-

Increased friction and localized overheating

Once abrasive particles enter the seal faces, wear accelerates exponentially.

Choose the Right Seal Face Materials (Critical)

Recommended Face Materials:

-

Silicon Carbide (SiC) – Excellent wear and corrosion resistance

-

Carburo de wolframio (TC) – Superior abrasion and impact resistance

Material Pairing Guidelines:

| Application Severity | Recommended Pairing |

|---|---|

| Mild slurry | Carbon vs SiC |

| Moderate slurry | SiC vs SiC |

| Severe abrasion | TC vs TC or TC vs SiC |

❌ Avoid ceramic faces in slurry service—they are brittle and wear rapidly.

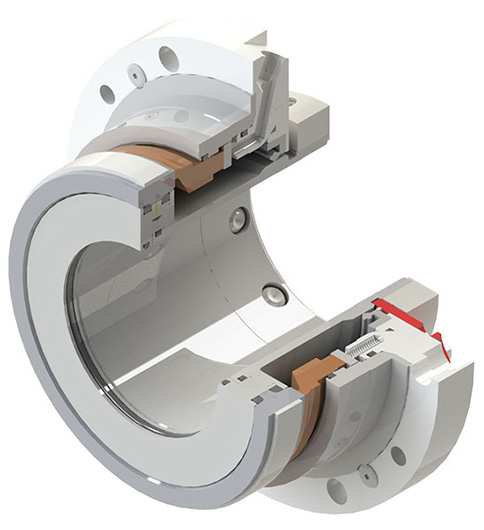

Seal Design Features That Reduce Abrasive Wear

1️⃣ Use Hard-Hard Face Combinations

Hard face pairs resist scratching and maintain flatness longer under abrasive exposure.

2️⃣ Select Wider Seal Faces

-

Wider faces distribute load more evenly

-

Reduce face pressure

-

Improve wear tolerance

3️⃣ Use Robust Springs or Bellows

-

Prevent spring clogging

-

Maintain consistent closing force

-

Metal bellows often outperform multiple small springs in slurry service

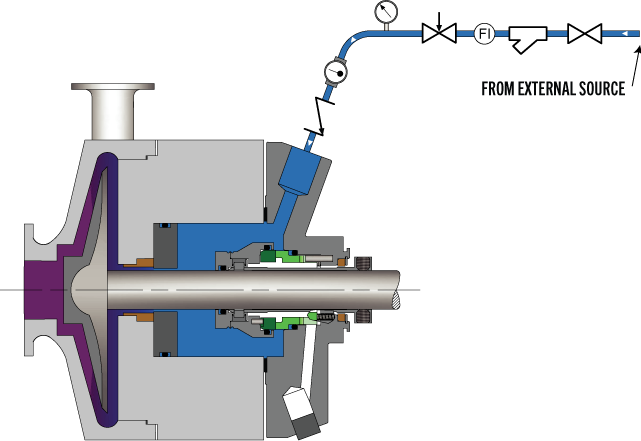

Control Particle Ingress with Flush and Seal Systems

Use External Flush (API Plan 32)

-

Introduces clean flush fluid at higher pressure

-

Prevents slurry from entering the seal chamber

-

Significantly reduces face wear

Consider Double Seals with Barrier Fluid

-

Fully isolates seal faces from abrasive media

-

Extends seal life dramatically

-

Higher cost, but often lower total lifecycle cost

In severe slurry service, double seals are often the only sustainable solution.

Reduce Shaft Movement and Vibration (Often Overlooked)

Abrasive environments magnify the effects of:

-

Shaft runout

-

Misalignment

-

Vibration

Even small dynamic movements allow particles to:

-

Penetrate the seal interface

-

Accelerate wear

-

Cause face chipping

Stable rotating equipment is essential for slurry seal reliability.

Installation and Maintenance Best Practices

During Installation:

-

Verify shaft runout and alignment

-

Ensure flush lines are clean and unobstructed

-

Avoid dry running during startup

During Operation:

-

Monitor flush pressure and flow

-

Inspect leakage trends

-

Watch for abnormal temperature rise

Common Mistakes in Slurry Seal Applications

-

Using single seals without flush

-

Selecting ceramic or soft face materials

-

Ignoring solids concentration changes

-

Treating slurry service like clean fluid service

These mistakes almost always result in short seal life and repeated failures.

FAQ: Mechanical Seals in Slurry and Abrasive Fluids

Q1: Can a single mechanical seal survive slurry service?

In mild slurry with proper flushing, sometimes. In severe slurry, double seals are strongly recommended.

Q2: Is Tungsten Carbide always better than Silicon Carbide?

Not always. TC excels in impact resistance, while SiC offers better corrosion resistance.

Q3: Does higher flush flow always improve seal life?

No. Flush flow must be controlled—too much can cause thermal shock or dilution issues.

Final Thoughts: Slurry Sealing Is a System Design Problem

Mechanical seals in slurry or abrasive fluids fail primarily due to particle ingress and face wear, not seal quality.

Reliable slurry sealing requires:

-

Correct material selection

-

Robust seal design

-

Effective flush or barrier systems

-

Stable rotating equipment

Design the system, not just the seal—and face wear will follow.

Call to Action (CTA)

👉 Struggling with rapid seal wear in slurry or abrasive applications?

Share your fluid composition, solids content, and operating conditions. Our technical team can recommend slurry-optimized mechanical seal designs and support systems to extend seal life.