Kettle Seal Manufacturer

– Providing stable and reliable shaft sealing solutions for reaction vessels, agitators and mixers.

Adopting corrosion-resistant structures and high-strength materials ensures that the material operates without leakage under high-temperature, high-pressure or vacuum conditions.

Understanding the Role of a Kettle Seal in Reactor Systems

En Sello de la caldera is a sealing device specifically designed for reaction vessels, agitators and mixers, used to prevent the leakage of liquids, slurries or volatile gases along the stirring shaft. It forms a sealing interface by the precise mating of the rotating ring and the stationary ring end faces, and can operate stably under positive pressure, negative pressure or even vacuum conditions.

Unlike ordinary mechanical seals for pumps, Sello de la caldera can adapt to the common shaft eccentricity, vibration and axial movement in agitating equipment. This makes it an irreplaceable key component in fields such as chemical engineering, pharmaceuticals, food and fine chemicals.

Its structural types are diverse, including single-end, double-end, jacketed cooling type, sanitary grade structure, and special designs suitable for high-temperature or dry running conditions, ensuring safe and reliable sealing in complex reaction environments at all times.

Why Kettle Seals Are Essential for Reactors

The reaction vessel operates under various complex conditions such as high temperature, corrosive media, vacuum or high pressure. Therefore, it must be equipped with a professional “kettle seal” to ensure safety and stability. The correct sealing structure can effectively prevent material leakage, avoid pollution in the production site or safety risks, and ensure that the equipment complies with environmental protection regulations.

The professional kettle seal can withstand temperatures ranging from 100 to 250°C and various acids, bases, and solvents. It is suitable for vacuum reactions, pressurized reactions, and continuous stirring processes. Its structural design can absorb axial movement and vibrations, thereby extending the service life of the bearings, the kettle body, and the mechanical seal itself, and reducing maintenance costs.

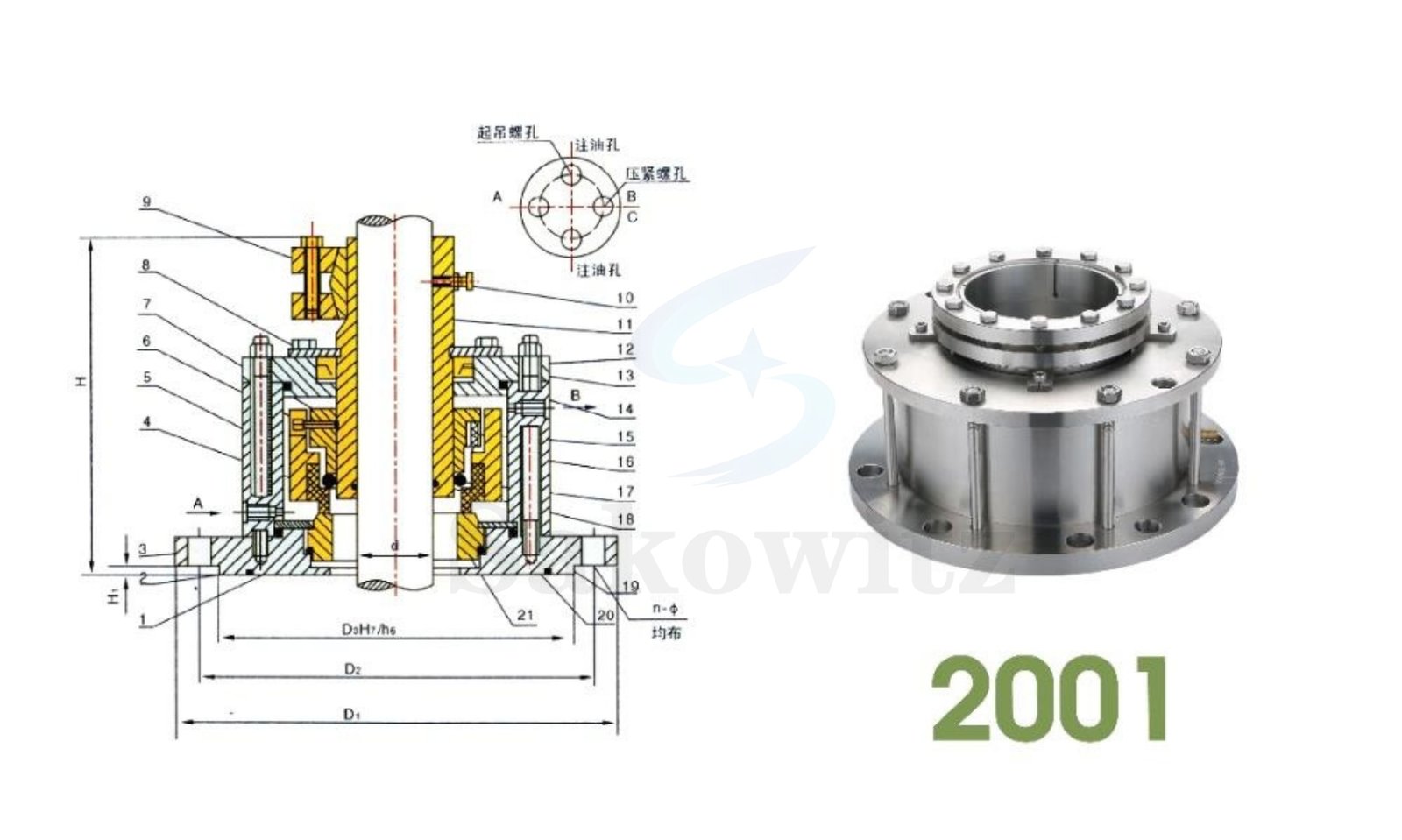

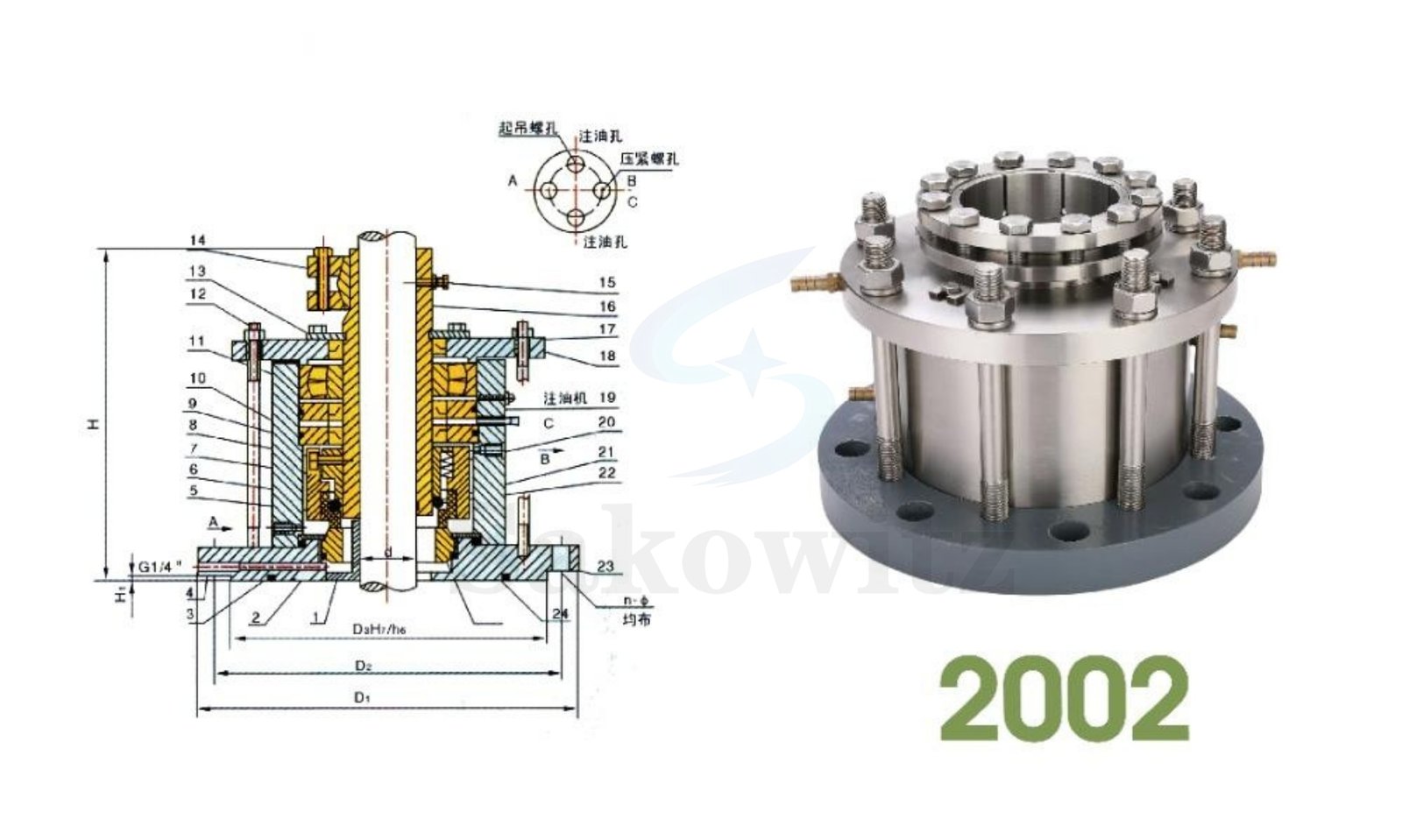

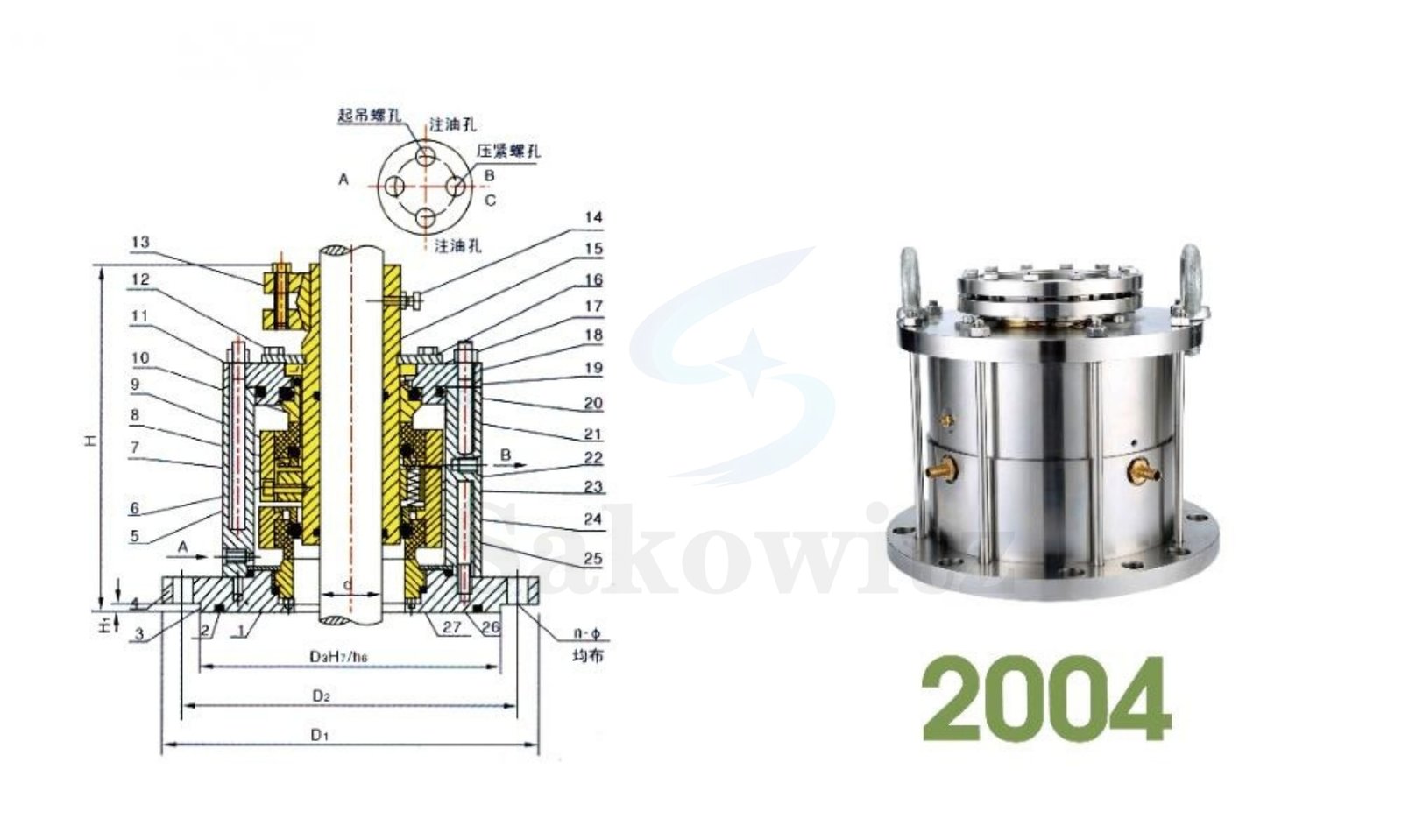

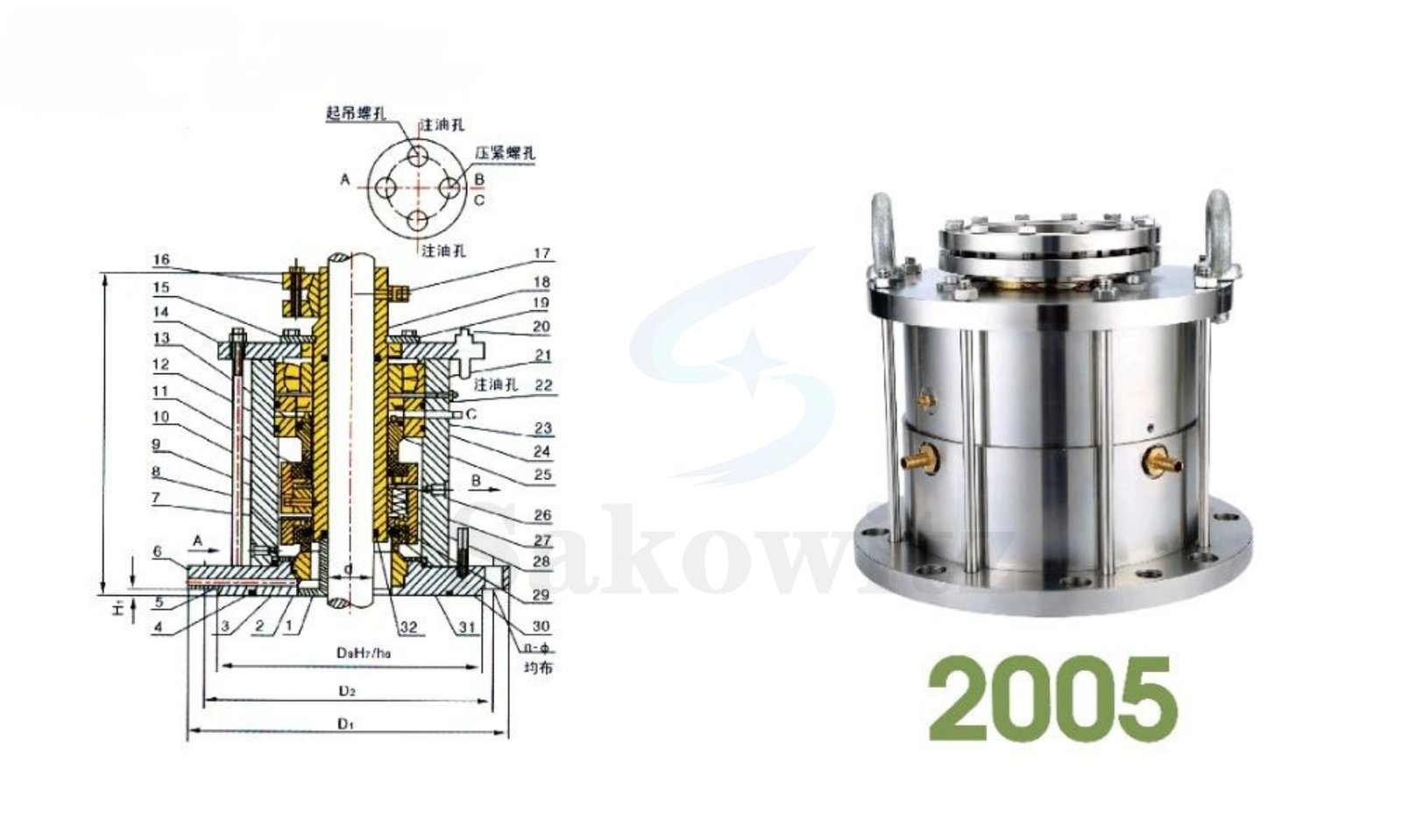

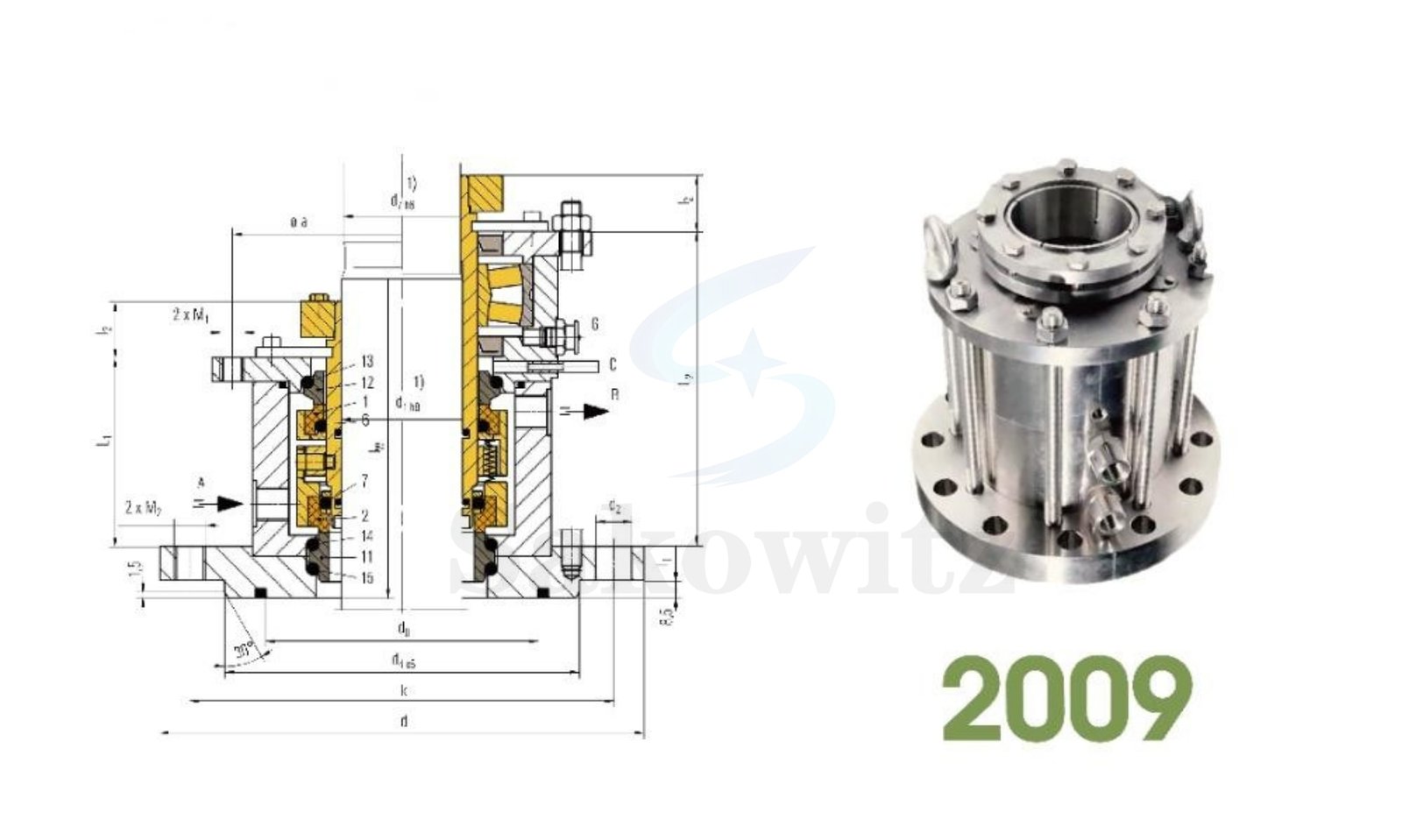

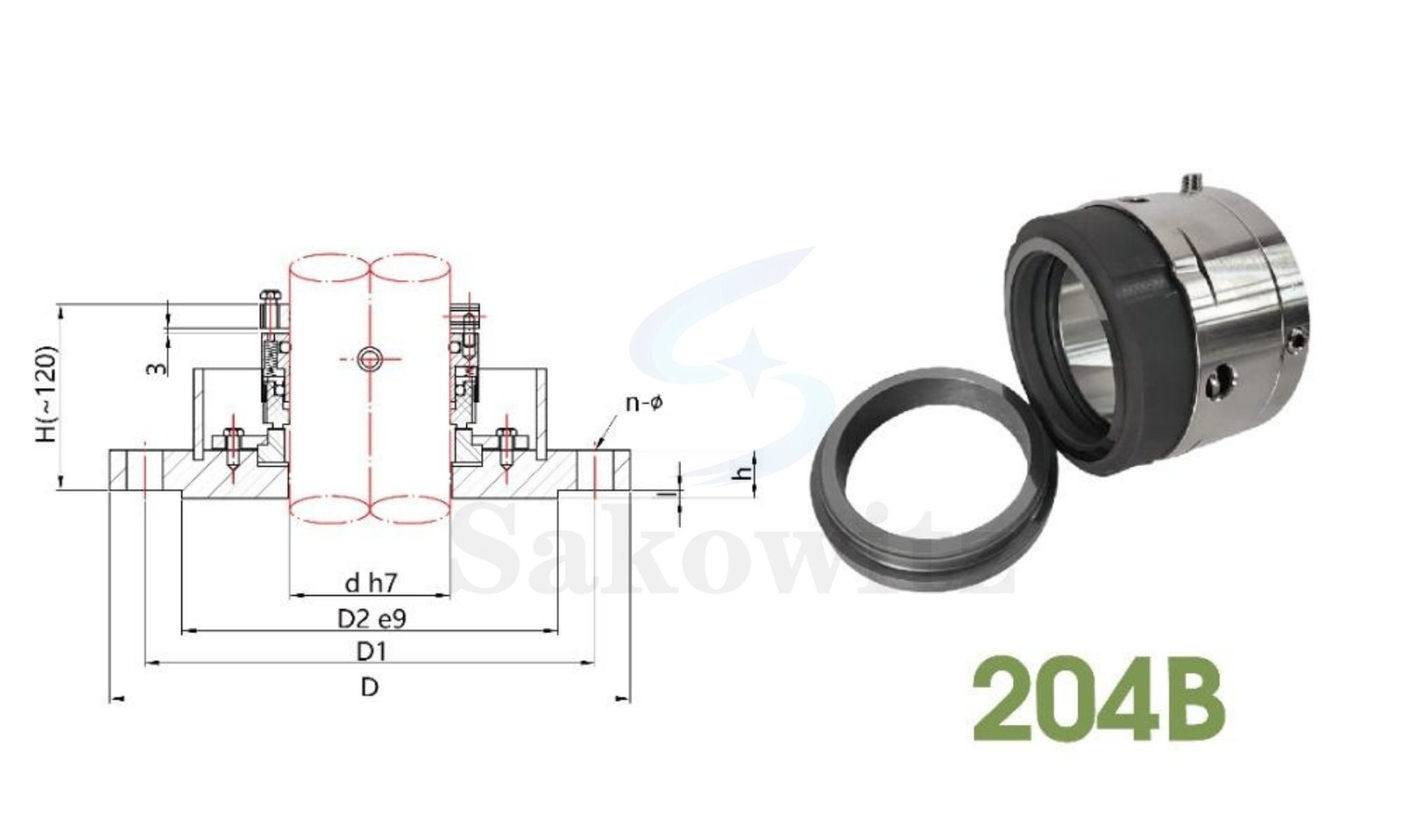

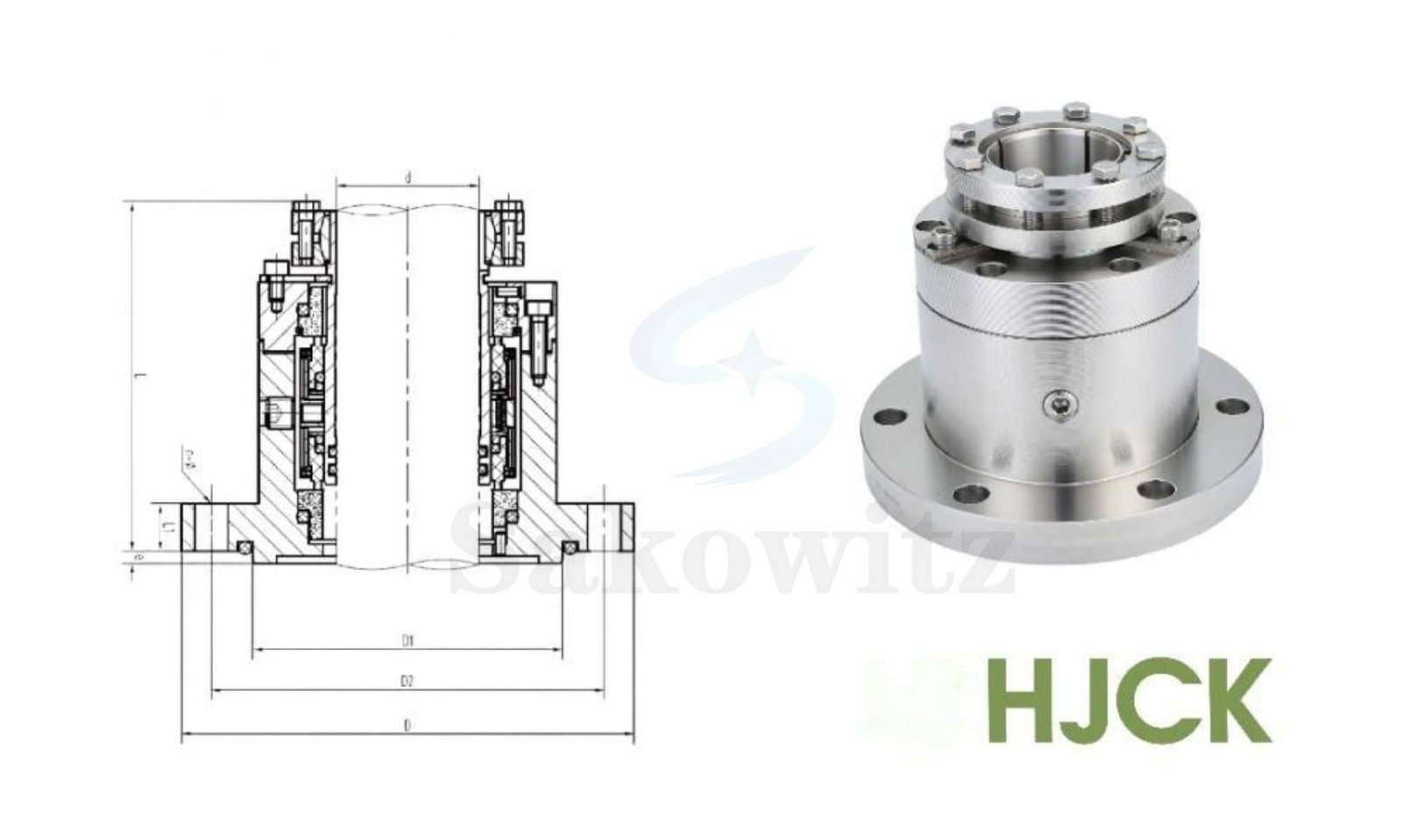

Kettle Mechanical Seal Product Series

Póngase en contacto con nuestros especialistas en cierres mecánicos si tiene alguna pregunta

Póngase en contacto con nosotros y nuestro equipo profesional de Sakowit le ayudará a encontrar el cierre mecánico más adecuado para mejorar la seguridad de su proyecto.

Advanced Kettle Seal Engineering by Sakowitz

Sakowitz specializes in the engineering design of high-performance kettle seals, ensuring that the seals maintain stable performance under high temperatures, corrosive media, and vacuum conditions. Our solution takes into account durability, hygiene, and adaptability, and can meet the various reaction process requirements from the chemical industry to the food industry.

- Multiple structural options available: Supports single-ended, double-ended, magnetic drive type, and structures with cooling jackets. The configuration can be freely adjusted according to the pressure and temperature of the reaction vessel.

- High-performance material combination: The friction surfaces use SiC, Carbon or WC; the elastomers select FFKM, PTFE, EPDM to be compatible with strong corrosive and high-temperature media.

- High-quality metal components: Uses SS316, Duplex, Hastelloy®, Titanium and other metals to enhance corrosion resistance and structural strength.

- Wide equipment compatibility: Suitable for various mixing equipment such as reaction vessels, agitation vessels, mixing tanks, blending vessels, and sterilization vessels.

- Compliant with international standards: All seals comply with API 682, ISO 21049, FDA, ATEX, CE and other international safety and hygiene standards.

- Deep customization capability: Supports customizing shaft diameter, differential pressure design, temperature grade and special material requirements (such as high viscosity, solvent-based, solid-containing slurries).

Sakowitz’s kettle seal is designed to enhance equipment reliability, reduce the risk of leakage, and ensure that the system can operate stably for a long time under harsh conditions.

Technical Specifications of Sakowitz Cartridge Mechanical Seals

| Parámetro | Especificación / Gama |

|---|---|

| Presión | ≤ 25 bar — suitable for pressurized and vacuum reactor systems |

| Temperatura | -40°C to +250°C — supports high-temperature chemical processes |

| Velocidad | ≤ 15–20 m/s — compatible with medium-speed agitator shafts |

| Materiales faciales | SiC / WC / Carbon — optimized for wear and chemical resistance |

| Elastómeros | FFKM / PTFE / EPDM / FKM — corrosion-resistant options for solvents and acids |

| Metales | SS316 / Duplex / Titanium / Hastelloy® — high-strength alloys for aggressive media |

| Conformidad | API 682 / ISO 21049 / FDA / CE / ATEX — meets global engineering and safety standards |

| Aplicaciones | Reactor kettles, mixing kettles, vacuum kettles, processing vessels |

Where Kettle Seals Are Used in Modern Industry

Used for solvent, acid-base and catalytic reaction vessels, it ensures stable sealing even under high temperature and strong corrosive conditions, reducing the risks of material evaporation and leakage.

Suitable for GMP hygiene-level reaction vessels, it can operate under vacuum, low temperature or sterile conditions, ensuring the cleanliness and safety of drug production.

It is widely used in mixing tanks for dairy products, syrups, seasonings, etc. The food-grade sealing material prevents contamination and meets strict hygiene standards.

Support vacuum emulsifiers and mixing tanks and other equipment, which can withstand high-viscosity materials and shear forces, ensuring uniform mixing and stable quality.

Suitable for high-viscosity resin and coating reaction vessels. The solvent-resistant structure can handle highly corrosive media, thereby extending the service life of the seal.

Used for sealing the stirring of sensitive materials such as electrolytes and lithium paste, it effectively prevents evaporation, leakage and contamination, ensuring the stability of the process.

Why Sakowitz Is the Trusted Choice for Kettle Seal Solutions

Sakowitz has over 30 years of experience in sealing design and manufacturing, and has been serving customers of global reaction vessels and mixing systems for a long time. We provide stable and longer-lasting kettle seal solutions. Our products can adapt to complex conditions such as high temperature, corrosion, vacuum and high pressure, and are a reliable choice for the chemical, pharmaceutical, food and new energy industries.

- Deep industry experience: Over 30 years dedicated to sealing technology, with extensive experience in reaction vessels and agitator vessels.

- Global customer trust: Equipment manufacturers and factories from over 50 countries and regions consider us as their core suppliers.

- High precision manufacturing quality: CNC processing accuracy can reach <2 µm, ensuring the sealing end face is highly flat and stable.

- Strong OEM substitution capability: Can replace international brands such as John Crane, EagleBurgmann, and Flowserve with their corresponding models.

- Full range of working condition solutions: Provide food-grade, explosion-proof, high-temperature, vacuum, and corrosive medium sealing solutions.

- Comprehensive technical services: Support rapid delivery, installation guidance, and global after-sales technical support.

FAQ – Common Questions About Kettle Seals

Q1: Can Sakowitz's kettle seal replace products from international brands?

Yes. We can replace international brands such as John Crane, EagleBurgmann, and Flowserve. We can also customize and match according to the specifications of the reaction vessel to ensure installation compatibility and sealing performance.

Q2: Are your seals suitable for vacuum reaction vessels?

Absolutely. Our kettle seal is compatible with -0.1 MPa vacuum as well as high-pressure positive pressure environments, and can maintain a stable seal throughout the entire working conditions of the reaction vessel.

Q3: How long does the kettle seal typically last?

It usually lasts for 3 to 5 years. The lifespan is affected by temperature, corrosiveness of the medium, stirring speed, and the condition of the bearings. High-quality lubrication and proper installation can significantly extend its service life.

Q4: Can it be used for food or pharmaceutical reaction vessels?

Yes. We offer materials that meet the requirements of FDA, USP Class VI, and hygienic grade (Hygienic Grade), including PTFE, EPDM and FFKM, which are suitable for highly clean environments.

Q5: Can you customize non-standard shaft diameters or special structures?

Yes, we can. We can carry out customized production based on drawings, samples or operating conditions parameters to meet requirements such as special shaft diameters, viscous materials, corrosive media, etc.

Enviar un presupuesto rápido

Por qué más de 1.000 clientes confían en nosotros

Excelencia en ingeniería: precisión que rinde

Cada junta Sakowit está diseñada, mecanizada y probada para ofrecer la máxima fiabilidad y una larga vida útil, incluso en los entornos más exigentes.

Rendimiento probado: fiable en todos los sectores

Con la confianza de ingenieros de todo el mundo por su rendimiento constante en sistemas de procesos químicos, de lodos y de alta exigencia.

Asistencia mundial: respuesta rápida, servicio de confianza

Una red mundial y un servicio de asistencia con gran capacidad de respuesta le garantizan la ayuda de expertos cuando la necesite, esté donde esté.