Mechanical seal leakage is one of the most common problems faced by industrial pump operators. While a small amount of vaporization or weepage may be normal during startup, continuous leakage is a clear warning sign that something is wrong.

Understanding the root cause of mechanical seal leakage is critical before replacing the seal or adjusting the pump. Otherwise, the same failure will repeat—sometimes even faster.

This article explains the most common leakage causes, how to diagnose them correctly, and how to prevent future failures.

1. Leakage Is a Symptom, Not the Problem

Many users treat leakage as a seal quality issue. In reality, over 70% of mechanical seal failures are caused by operating conditions or installation errors, not the seal itself.

Before selecting a replacement, you should always ask:

-

When did the leakage start?

-

Did it happen immediately or after weeks/months?

-

Was there any change in operating conditions?

These answers determine the real cause.

2. Common Mechanical Seal Leakage Causes

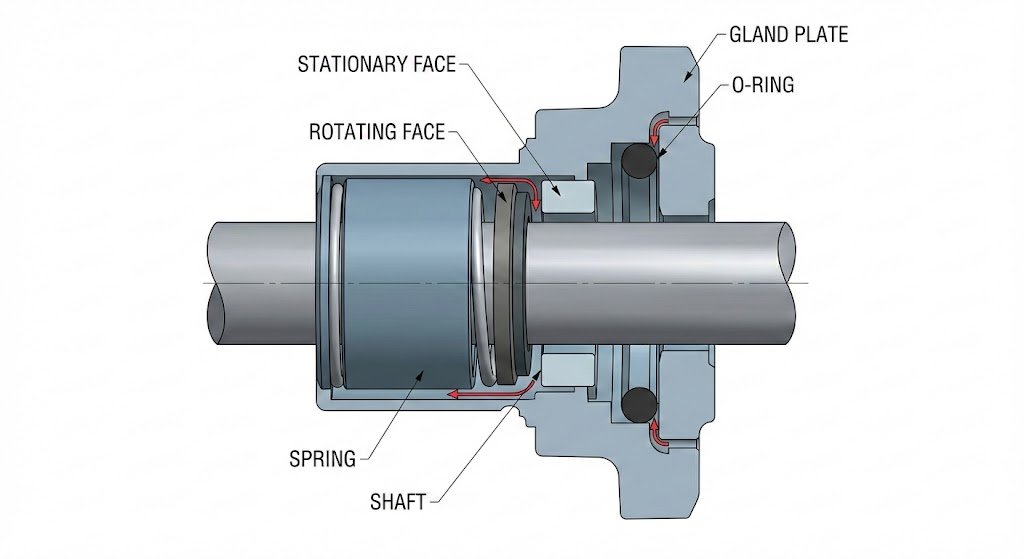

2.1 Incorrect Installation or Misalignment

Improper installation remains the number one reason for early seal leakage.

Typical issues include:

-

Shaft runout exceeding tolerance

-

Improper axial setting

-

Uneven tightening of gland bolts

-

Contaminated seal faces during installation

Even a high-quality cartridge seal can fail if installed incorrectly.

2.2 Dry Running or Poor Lubrication

Mechanical seals rely on a thin fluid film between seal faces. If this film disappears—even for a few seconds—the seal faces can overheat and crack.

Common reasons:

-

Pump running dry during startup

-

Blocked flush line

-

Incorrect seal chamber design

Once thermal damage occurs, leakage is unavoidable.

2.3 Excessive Vibration

Vibration accelerates seal face wear and disturbs face alignment.

Possible sources:

-

Bearing wear

-

Cavitation

-

Shaft imbalance

-

Incorrect pump selection

If vibration is not controlled, replacing the seal alone will not solve the problem.

2.4 Incompatible Seal Materials

Seal material selection must match:

-

Process media

-

Temperatura

-

Presión

-

Chemical compatibility

For example:

-

FKM may harden under extreme heat

-

Carbon faces may wear rapidly in abrasive media

-

Elastomers may swell in certain solvents

Material mismatch often leads to gradual leakage rather than sudden failure.

3. How to Diagnose the Leakage Correctly

Before ordering a new mechanical seal, collect the following information:

✔ Leakage location (shaft side, gland, seal faces)

✔ Operating temperature and pressure

✔ Pump speed (RPM)

✔ Process fluid description

✔ Installation time and failure time

Photos or drawings are extremely helpful for accurate analysis.

4. Preventing Repeated Mechanical Seal Failures

To avoid repeated leakage problems:

-

Verify shaft and housing tolerances

-

Use proper installation tools and procedures

-

Confirm seal materials with the actual operating media

-

Consider upgrading to a cartridge mechanical seal for critical applications

-

Improve seal flushing and cooling systems

A systematic approach always costs less than repeated emergency replacements.

5. When to Consider a Customized Mechanical Seal Solution

Standard seals work well in many applications, but customized or application-specific seals are recommended when:

-

Temperature is extremely high or unstable

-

Media contains solids or crystals

-

Equipment operates under frequent start-stop conditions

-

Downtime cost is significant

In such cases, proper seal design matters more than seal price.

Reflexiones finales

Mechanical seal leakage is never accidental. It always has a cause.

Correct diagnosis saves time, money, and unnecessary downtime. If you are unsure about the leakage cause, providing photos, drawings, or operating data is the fastest way to find the right solution.

👉 https://sakowit.com/cartridge-mechanical-seal-failure-causes/