Compressor Mechanical Seal Manufacturer

Sakowit designs and manufactures high-performance mechanical seals for industrial compressors. Our seals deliver leak-free performance, high efficiency, and long-term reliability across gas, oil, and process industries.

Understanding Compressor Mechanical Seals and Their Function

The mechanical seal of the compressor is a crucial component designed to prevent the leakage of gases or liquids. It is installed at the end of the rotating shaft of the compressor, forming a highly precise sealing interface between the moving ring and the stationary ring. As the shaft rotates, there is only a thin liquid film of 1–3 micrometers between the sealing end faces. This extremely thin lubricating film not only reduces friction but also prevents the leakage of process gases.

Compared with traditional packing seals or lip seals, mechanical seals can achieve a higher level of sealing. In industrial gas compression systems, their leakage rate can be controlled below 10⁻³ mbar·L/s, meeting the international sealing standards of API 682 y ISO 21049. This sealing method significantly enhances the operating efficiency, safety and service life of the compressor.

Why Reliable Mechanical Seals Are Critical for Compressors

The compressor operates under high pressure and high speed conditions. Any minor leakage could lead to loss of gas, decrease in efficiency or safety hazards. The mechanical seal achieves this through high-precision end face alignment, forming a very thin gas or liquid film between the moving and stationary rings, effectively preventing the medium from leaking along the shaft.

Compared to traditional packing seals, mechanical seals can achieve a more stable sealing effect. In industrial compression systems, their leakage can be reduced by more than 90%, the operating efficiency can be increased by approximately 5-10%, and the maintenance intervals of the equipment can be significantly extended (on average, by 40-60%).

Mechanical seals can also maintain the purity of the process gas, preventing cross-contamination between lubricating oil and gas, and ensuring the product quality and system safety in the chemical, petrochemical and pharmaceutical industries.

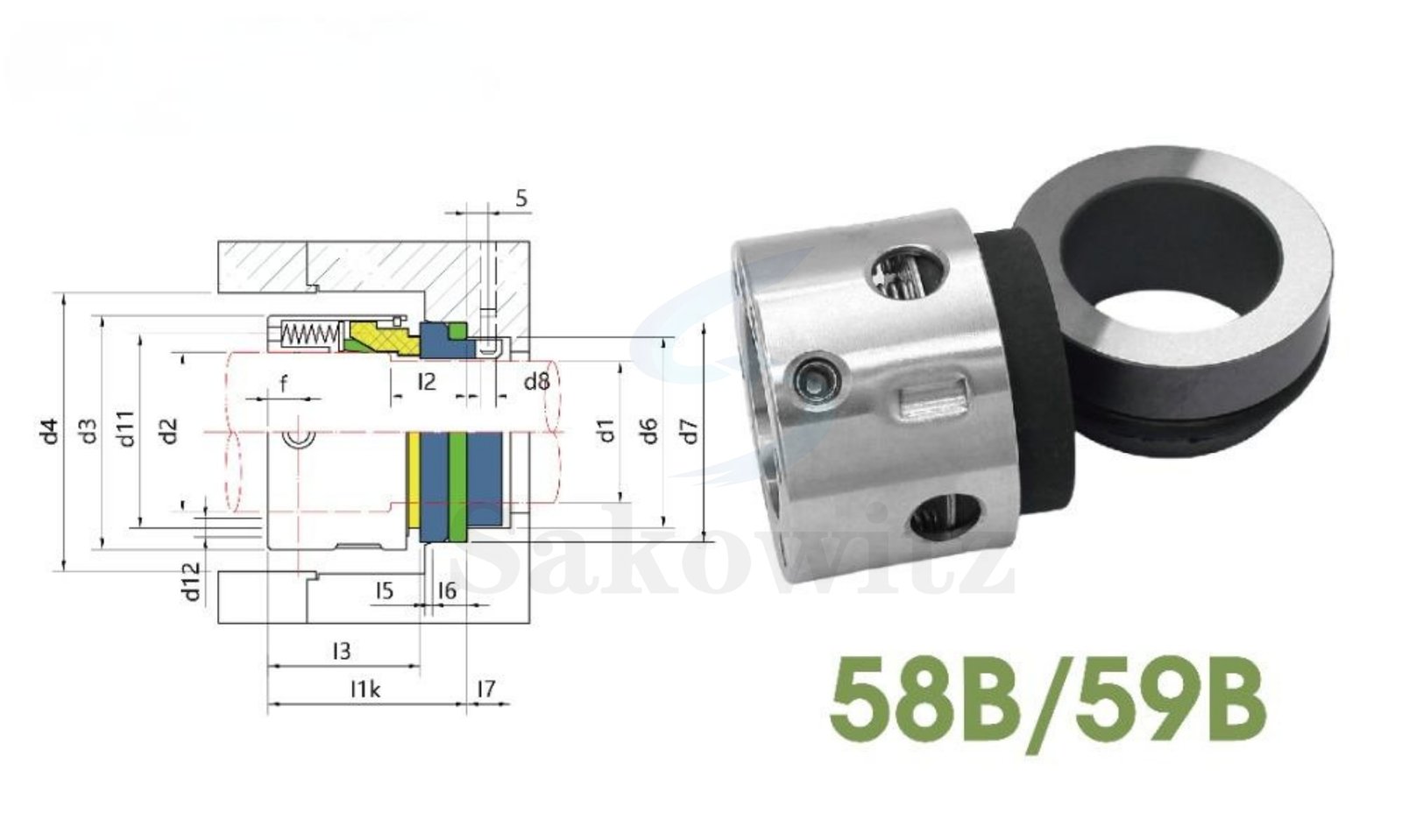

Compressor Mechanical Seals Product Series

Póngase en contacto con nuestros especialistas en cierres mecánicos si tiene alguna pregunta

Póngase en contacto con nosotros y nuestro equipo profesional de Sakowit le ayudará a encontrar el cierre mecánico más adecuado para mejorar la seguridad de su proyecto.

Sakowitz Engineering Solutions for High-Performance Compressor Mechanical Seals

Sakowitz specializes in the design of compressor seals under high-pressure, complex media, and high-speed rotating conditions. Our mechanical seals have undergone rigorous engineering calculations and on-site verification, and can maintain stable sealing performance under working pressures up to 80 bar and rotational speeds up to 60 m/s.

The sealing structure supports single-end, double-end y dry gas seal configurations. The moving and stationary rings are made of silicon carbide (SiC), carbon o tungsten carbide, which can effectively resist wear, cavitation and thermal deformation, ensuring the stability of the end face under high-pressure gas compression and high-speed friction conditions.

The metal components are made of corrosion-resistant alloys such as Hastelloy®, Inconel®, SS316, etc. They can maintain strength and corrosion resistance even in harsh media containing hydrogen sulfide, chloride, or fluoride. All products comply with international standards such as API 682, ISO 21049, ASME, and have passed leak, pressure resistance and thermal cycling tests.

Sakowitz seal is widely applicable to centrifugal, screw and reciprocating compressors. It demonstrates outstanding stability and reliability in the petrochemical, natural gas, hydrogen, air separation and refrigeration industries.

Technical Specifications of Compressor Mechanical Seals

Sakowit compressor mechanical seal is specifically designed for high-pressure gas conditions. Every structural detail has been verified through engineering, ensuring stable sealing performance even under high temperatures, high speeds, and high pressures. The sealing material and manufacturing process comply with the international standards of API 682 / ISO 21049, and have passed multiple pressure and thermal cycle tests to meet the requirements for long-term operation.

| Parámetro | Gama / Especificación | Engineering Notes |

|---|---|---|

| Presión | Up to 100 bar | Suitable for high-pressure gas compression and sealing environments such as hydrogen and ammonia. |

| Temperatura | -40°C ~ +250°C | Designed for continuous operation under extreme hot or cold conditions. |

| Velocidad | Up to 60 m/s | Ideal for high-speed centrifugal and turbo compressor shafts. |

| Materiales faciales | SiC / WC / Carbono | Provides high hardness and wear resistance, reducing face friction and wear. |

| Elastómeros | FKM / FFKM / PTFE | Excellent chemical resistance and superior gas sealing performance. |

| Metales | SS316 / Inconel® / Hastelloy® | Corrosion- and heat-resistant, ensuring long-term structural integrity. |

| Conformidad | API 682 / ISO 21049 / CE / ATEX | Fully compliant with international industrial and safety standards. |

Key Industries and Applications of Compressor Mechanical Seals

Sakowit slurry pump seals are widely used in highly abrasive, high-solids, and highly corrosive operating conditions. We are committed to providing stable, durable, and low-maintenance sealing solutions for customers worldwide.

It is used in high-pressure gas compression systems such as hydrogen, natural gas and propane. Sakowit mechanical seals can operate for a long time in environments containing corrosive media, effectively preventing gas leakage and ensuring the safety and environmental protection compliance of refining and chemical facilities.

It is widely applied in natural gas gathering and transportation, gas pressurization and liquefaction equipment. The sealing structure can withstand a pressure of up to 100 bar, ensuring the safety and reliability of the high-pressure conveying system under continuous working conditions.

It is applicable to gas compressors such as oxygen, nitrogen, carbon dioxide and hydrogen. The sealing materials comply with the standards for oil-free and high-purity gas applications, ensuring gas purity and equipment operational efficiency.

It is used in gas turbines, steam turbines and gas pressurization systems of power plants. The high-temperature and pressure-resistant design enables stable operation in high-speed shaft systems, effectively reducing energy consumption and equipment vibration.

It is applicable to the compression of chemical media such as ammonia, Freon and chlorine. Sakowitz seals are made of Hastelloy with high-corrosion-resistant materials such as FFKM.

Designed specifically for hydrogen, carbon dioxide capture and green energy systems. The sealing structure features an ultra-low leakage rate (as low as 10⁻³ mbar·L/s), meeting the high safety and environmental protection requirements of hydrogen energy equipment.

Why Global Engineers Trust Sakowitz Compressor Mechanical Seals

With over 30 years of experience in sealing engineering, Sakowit has become a global technical benchmark in the field of compressor sealing. Our products have been installed and used in more than 45 countries, serving a cumulative total of over 15,000 compressor systems. Whether in the petrochemical, natural gas, air separation, or hydrogen energy systems, Sakowitz seals consistently maintain high precision, long lifespan and zero leakage performance.

Our seals are manufactured using CNC precision processing technology, with the end face flatness controlled at <2 μm. This ensures stable adhesion even under high pressure and high-speed operation. Both the metal and the sealing materials have been carefully selected, using industrial-grade materials such as Hastelloy®, Inconel®, SS316, SiC, Carbon, etc., which possess outstanding corrosion resistance, wear resistance and high-temperature resistance properties.

Sakowit offers global technical support with rapid response y OEM replacement compatibility solutions, helping customers reduce downtime and extend maintenance cycles. All products comply with API 682, ISO 21049 and CE/ATEX standards, maintaining stability and reliability in harsh gas compression conditions.

Frequently Asked Questions about Compressor Mechanical Seals

Q1: Can Sakowitz seals replace my OEM compressor seal?

Certainly. Sakowit offers standard replacement models (drop-in replacements) and supports custom designs tailored to equipment dimensions and operating conditions. Whether screw, centrifugal or reciprocating compressors, we provide compatible solutions.

Q2: What is the typical service life of Sakowitz seals?

Under standard operating conditions, the seal’s service life is typically 3–5 years. This duration depends on the gas type, pressure, rotational speed, and maintenance intervals. Compared to conventional sealing methods, Sakowitz seals exhibit an average service life extension of approximately 40–60%.

Q3: Do you supply seals for oil-free or dry gas compressors?

Sakowitz’s non-contact dry gas seal is suitable for oil-free gas compression systems, achieving leakage rates as low as 10⁻³ mbar·L/s. It meets the requirements for clean gases and high-purity processes.

Q4: Are your seals compliant with international standards?

Fully compliant. All designs are manufactured in accordance with API 682, ISO 21049, CE and ATEX standards. Each seal undergoes leakage, pressure resistance and temperature resistance testing prior to dispatch. This ensures compliance with global industry safety and quality requirements.

Enviar un presupuesto rápido

Por qué más de 1.000 clientes confían en nosotros

Excelencia en ingeniería: precisión que rinde

Cada junta Sakowit está diseñada, mecanizada y probada para ofrecer la máxima fiabilidad y una larga vida útil, incluso en los entornos más exigentes.

Rendimiento probado: fiable en todos los sectores

Con la confianza de ingenieros de todo el mundo por su rendimiento constante en sistemas de procesos químicos, de lodos y de alta exigencia.

Asistencia mundial: respuesta rápida, servicio de confianza

Una red mundial y un servicio de asistencia con gran capacidad de respuesta le garantizan la ayuda de expertos cuando la necesite, esté donde esté.