Cartridge mechanical seals are widely used for their reliability, ease of installation, and reduced risk of assembly errors.

Cartridge mechanical seals are widely used for their reliability, ease of installation, and reduced risk of assembly errors.

However, in real industrial applications, seal failures still occur — even when cartridge seals are selected.

Understanding why these failures happen requires separating two critical factors: installation quality y actual operating conditions.

Installation Issues: Problems Before the Pump Starts

Although cartridge mechanical seals are pre-assembled, installation-related issues remain a common cause of early failure.

Typical installation problems include:

-

Improper shaft or sleeve surface condition

-

Excessive runout or misalignment

-

Incorrect tightening sequence or torque

-

Failure to remove setting clips

-

Contamination introduced during handling

These issues often lead to leakage or overheating shortly after startup, giving the false impression that the seal itself is defective.

Operating Conditions: Problems That Appear Over Time

In many cases, cartridge mechanical seals are installed correctly but fail due to operating conditions that differ from design assumptions.

Common operating-related causes include:

-

Pressure or temperature exceeding seal design limits

-

Dry running during startup or process interruption

-

Inadequate or unstable flush plans

-

Chemical incompatibility with seal face or elastomer materials

-

Vibration caused by pump or system instability

These factors usually result in gradual wear, face damage, or secondary seal degradation rather than immediate leakage.

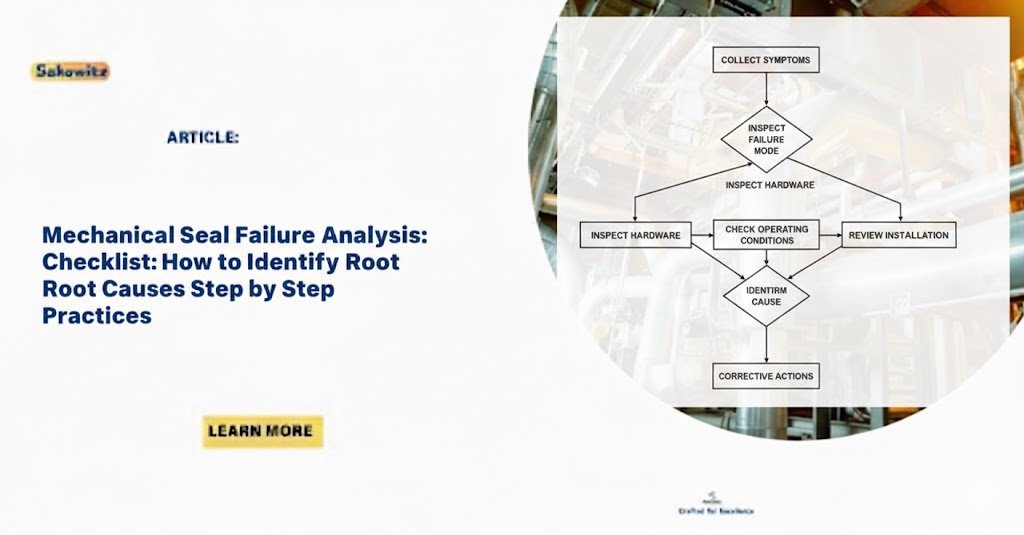

Installation vs Operating Conditions: How to Identify the Real Cause

Distinguishing between installation-related failure and operating-related failure is critical for corrective action.

A simplified guideline:

-

Early leakage or immediate failure → Often installation-related

-

Gradual leakage after stable operation → More likely operating conditions

-

Overheated faces or discoloration → Dry running or poor flushing

-

Elastomer cracking or swelling → Material incompatibility

Accurate failure analysis prevents repeated seal replacement without solving the root problem.

Why Cartridge Mechanical Seals Are Still the Right Choice

It is important to note that cartridge mechanical seals are not the problem — misunderstanding their limitations is.

When properly installed and correctly matched to operating conditions, cartridge seals offer:

-

Consistent seal face compression

-

Reduced human error

-

Shorter maintenance time

-

Improved reliability in demanding applications

The key is aligning seal selection, installation practice, and real process conditions.

Reflexiones finales

Cartridge mechanical seal failures rarely have a single cause.

Most failures result from the combined effects of installation quality and operating conditions.

Recognizing this distinction helps engineers, maintenance teams, and buyers make better decisions — not only about seal selection, but about system design and operation as a whole.