Introduction: Why Dry Running Is One of the Fastest Seal Killers

Dry running is one of the most destructive operating conditions for mechanical seals.

Unlike gradual wear or chemical attack, dry running can destroy seal faces within seconds or minutes.

Many seal failures labeled as “sudden” or “unexplained” are actually caused by short periods of dry running during startup, shutdown, or abnormal operating conditions.

This article explains what happens during dry running, how to recognize early warning signs, and practical methods to prevent dry running failures in pump systems.

What Is Dry Running in Mechanical Seals?

Dry running occurs when seal faces operate without adequate liquid lubrication between them.

Mechanical seals rely on a thin fluid film to:

-

Separate the seal faces

-

Remove heat

-

Reduce friction

When this fluid film disappears, direct face-to-face contact occurs, causing rapid heat buildup and damage.

What Happens During Dry Running?

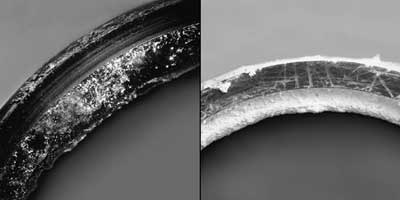

Immediate Effects on Seal Faces

-

Friction increases dramatically

-

Seal face temperature rises rapidly

-

Lubrication film collapses

Typical Damage Mechanisms

-

Carbon face glazing or burning

-

Ceramic or SiC face cracking

-

Thermal shock damage

-

Face blistering and distortion

In severe cases, seal faces can reach destructive temperatures in seconds.

Common Causes of Dry Running

Dry running is usually a system issue, not a seal design problem.

Most Common Causes:

-

Pump started without priming

-

Loss of suction or vapor lock

-

Closed suction valve

-

Insufficient flush flow

-

Improper API flush plan

-

Air entrainment in process fluid

Short, repeated dry running events are often more damaging than one long event.

How to Detect Dry Running Early

Visual Signs on Failed Seals

-

Burn marks on carbon faces

-

Bluish discoloration on metal parts

-

Cracked or shattered brittle faces

-

Melted or hardened elastomers

Operational Warning Signs

-

Sudden temperature increase near seal chamber

-

Audible squealing or screeching noise

-

Sudden leakage after startup

-

Abnormal vibration during startup

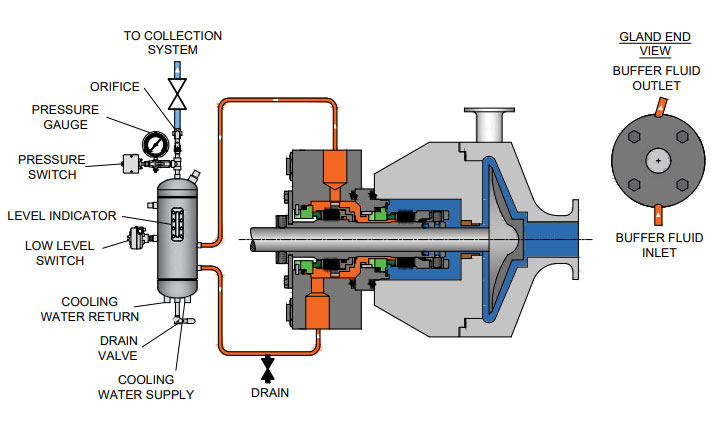

Instrumentation-Based Detection

-

Seal chamber temperature sensors

-

Flow switches on flush lines

-

Pressure monitoring in barrier or buffer systems

Why Some Seal Materials Fail Faster in Dry Running

Material selection affects how fast damage occurs, not whether damage occurs.

| Material | Dry Running Resistance |

|---|---|

| Carbon | Better short-term tolerance |

| Ceramic | Poor |

| Silicon Carbide | Poor–Medium |

| Tungsten Carbide | Medium |

No mechanical seal face material is designed for sustained dry running.

How to Prevent Dry Running in Mechanical Seals

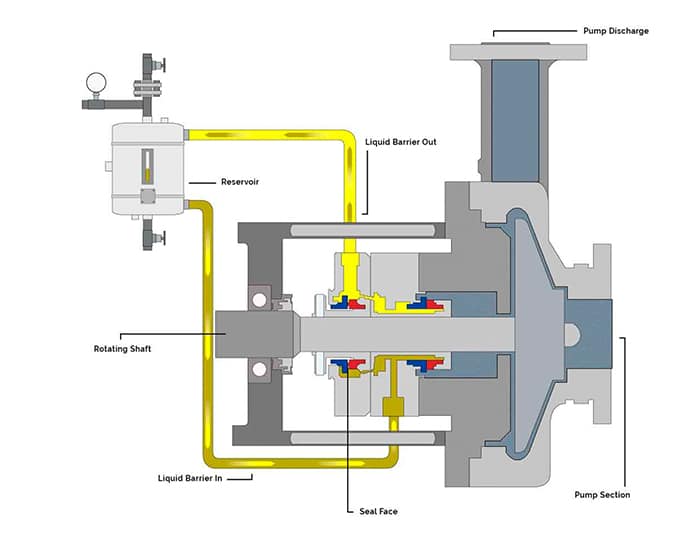

Design-Level Prevention

-

Use double mechanical seals in high-risk applications

-

Apply proper API flush plans (Plan 23, 32, 52, or 53)

-

Ensure continuous lubrication during startup

Operational Prevention

-

Always prime pumps before startup

-

Verify suction conditions

-

Avoid running pumps at very low flow rates

-

Follow proper startup and shutdown procedures

Monitoring & Protection

-

Install temperature or flow interlocks

-

Use seal support systems with alarms

-

Shut down equipment automatically during abnormal conditions

When Dry Running Cannot Be Fully Avoided

In some applications, short dry-running events are unavoidable.

In these cases:

-

Use carbon-based primary faces

-

Minimize startup time

-

Increase operator awareness

-

Accept reduced seal life as a trade-off

FAQ: Dry Running and Mechanical Seals

Q1: Can a mechanical seal survive dry running?

Only for very short periods. Sustained dry running will always cause failure.

Q2: Are cartridge seals better for dry running?

They reduce installation errors but do not eliminate dry running risk.

Q3: Can better materials solve dry running problems?

No. Materials may delay failure but cannot prevent damage without lubrication.

Final Thoughts: Dry Running Is a System Problem, Not a Seal Problem

Dry running is one of the fastest and most destructive causes of mechanical seal failure.

Preventing it requires proper system design, correct operating procedures, and effective monitoring.

Mechanical seals fail quickly under dry running — but systems fail first.

Fix the system, and the seal will survive.

Call to Action (CTA)

👉 Facing repeated dry running seal failures?

Share your pump startup procedure, suction conditions, and seal configuration. Our technical team can help identify dry running risks and recommend more robust sealing solutions.

👉https://sakowit.com/how-to-identify-the-root-cause-of-mechanical-seal-leakage-in-industrial-pumps/