Cartridge Mechanical Seals Manufacturer

– Providing reliable sealing solutions for all kinds of pumps and rotating equipment

The pre-assembled structure is easy to install and has a stable sealing effect, helping industrial users improve system operation efficiency.

Understanding Cartridge Mechanical Seals for Reliable Pump Performance

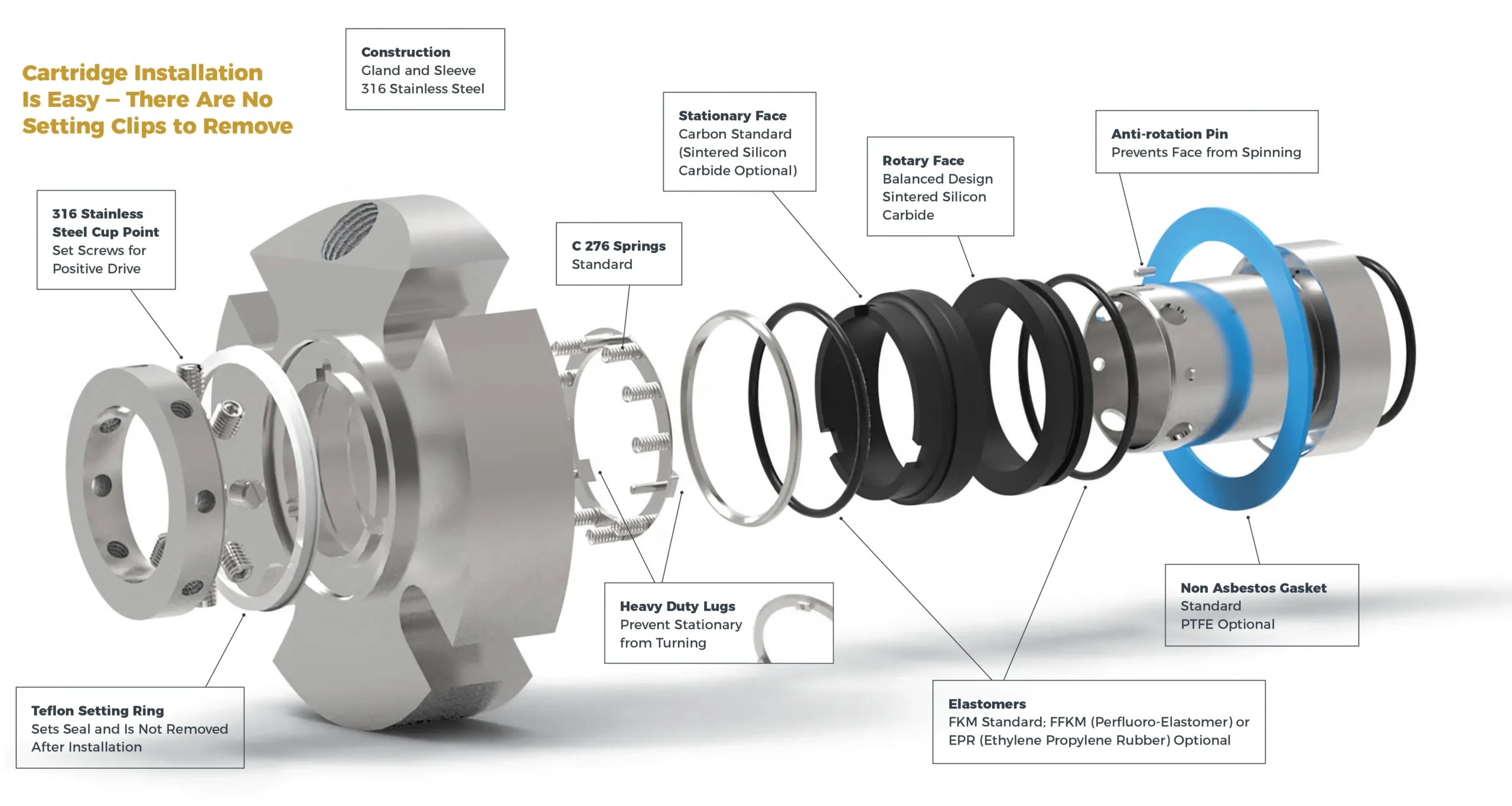

A cartridge mechanical seal is a complete sealing unit in which the rotating ring, stationary ring, spring and auxiliary sealing components are pre-assembled. This design makes installation easy and eliminates the need to adjust the compression amount or alignment, significantly reducing human assembly errors.

It is typically used in high-pressure, corrosive or hard-to-maintain working conditions and can maintain high sealing reliability during long-term operation. Pump systems using cartridge seals can reduce maintenance time by approximately 30% and effectively extend the service life of equipment.

Advantages of Cartridge Mechanical Seals in Industrial Applications

Cartridge mechanical seals, with their modular structure and high reliability, have become the preferred solution for industrial pump sealing. They are precisely assembled and tested before leaving the factory, allowing users to simply install and put them into use without the need for complicated adjustments. This type of seal not only reduces assembly errors but also effectively lowers the risk of leakage.

In high-pressure, high-temperature or chemically corrosive environments, cartridge mechanical seals demonstrate outstanding stability and durability. Practice has shown that compared with traditional independent seals, cartridge seals can extend operating life by 40% to 60%, and significantly reduce maintenance frequency and downtime losses.

Cartridge Mechanical Seal Product Series

Póngase en contacto con nuestros especialistas en cierres mecánicos si tiene alguna pregunta

Póngase en contacto con nosotros y nuestro equipo profesional de Sakowit le ayudará a encontrar el cierre mecánico más adecuado para mejorar la seguridad de su proyecto.

Sakowitz Solution – Cartridge Seal Design Expertise

Sakowitz has over 30 years of experience in sealing engineering and specializes in providing high-performance Cierres mecánicos de cartucho for various industries. Each product is meticulously designed, CNC processed, and factory tested to ensure easy installation and reliable operation.

- Multi-pump compatibility: Suitable for centrifugal pumps, mixers, compressors, and mixing tanks and other industrial equipment.

- Diverse structures: Offer single-ended, double-ended, balanced, unbalanced, and dry gas seal options.

- High-quality material combinations: The sealing end faces can be selected from silicon carbide (SiC), graphite (Carbon), and tungsten carbide (WC); the elastomers can be FKM, EPDM, and PTFE.

- Corrosion-resistant metal structure: Utilize SS316, duplex steel (Duplex), and Hastelloy®, suitable for high-temperature and high-pressure environments.

- Compliant with international standards: All products meet the requirements of API 682, ISO 21049, ATEX, and CE certifications.

- Modular design concept: Factory-assembled (Pre-assembled), with an installation success rate of 100%.

Technical Specifications of Sakowitz Cartridge Mechanical Seals

Sakowitz’s Cartridge Mechanical Seals have been precisely designed and repeatedly verified to maintain stable sealing performance under high pressure, high temperature and complex operating conditions. All seals are made of high-grade materials and strictly follow international industrial standards to ensure long-term reliable operation in various pump and compressor systems.

| Parámetro | Especificación / Gama |

|---|---|

| Presión | ≤ 40 bar — Suitable for high-pressure pumps and compressor systems |

| Temperatura | -40°C ~ +250°C — Designed to operate under extreme hot and cold conditions |

| Velocidad | ≤ 50 m/s — Ideal for high-speed rotating shafts |

| Materiales faciales | SiC / WC / Carbon — Provides excellent wear resistance and low friction |

| Elastómeros | FKM / EPDM / FFKM / PTFE — Offers superior chemical resistance and flexibility |

| Componentes metálicos | SS316 / Duplex / Hastelloy® — Ensures structural strength and corrosion resistance |

| Normas | API 682 / ISO 21049 / CE / ATEX — Complies with international safety and engineering certifications |

| Aplicaciones | Pumps, Compressors, Mixers, Agitators, and other rotating equipment |

Global Industries Using Cartridge Mechanical Seals

Sakowitz’s Cierres mecánicos de cartucho are widely used in several critical industrial sectors. With high precision manufacturing and excellent pressure resistance and corrosion resistance properties, they provide reliable sealing solutions for complex working conditions.

Address the sealing requirements for highly corrosive liquids and gases, ensuring production safety and pure medium.

Designed for high pressure, can operate stably in oilfield pumps and transportation pipeline systems.

Suitable for submersible pumps, centrifugal pumps and municipal water supply systems, reducing leakage and maintenance frequency.

Utilizes hygienic materials, complies with FDA standards, ensuring pollution-free production.

Used in steam turbines and cooling systems, supporting high-temperature and high-speed sealing.

Strong anti-sea water corrosion performance, extending the lifespan of pump systems.

Why Choose Sakowitz

With over 30 years of experience in sealing engineering, Sakowitz provides global customers with high-precision and highly reliable Cierres mecánicos de cartucho. Our products are widely used in pumps, compressors and mixing equipment, and have earned the trust of OEMs and industrial users with their outstanding performance.

- Una rica experiencia: Over 30 years of expertise in mechanical seal design and manufacturing, familiar with various working conditions.

- Global Application: More than 20,000 sets of products installed, serving 50+ countries and regions.

- Ultra-Precision: CNC processing accuracy less than 2 micrometers, ensuring perfect seal fit.

- Strong OEM Compatibility: Can directly replace the original seals of mainstream pump brands.

- Corrosion and Abrasion Resistance Materials: Use high-performance materials such as SS316, Hastelloy®, and silicon carbide.

- Global Technical Support: Quick delivery, prompt response, providing professional engineering consultation for customers.

FAQ – Common Questions About Cartridge Mechanical Seals

Q1: Can Sakowitz's cartridge mechanical seal replace the original factory seal?

OK. Sakowitz offers OEM equivalent designs y custom replacement solutions, which can be directly installed without the need to modify the equipment structure.

Q2: How long is the typical service life of a cartridge mechanical seal?

It is usually 3 to 5 years, depending on the type of medium, operating pressure and maintenance frequency.

Under reasonable operating conditions, the lifespan can be extended to more than 1.5 times that of ordinary seals.

Q3: Is it applicable to high-temperature or corrosive fluids?

Applicable. Sakowitz offers models using Hastelloy® and FFKM and other high-performance materials, which can maintain stable sealing in high-temperature and highly corrosive environments.

Q4: Do you support the API Plan assistance system?

Support. We can provide lubrication and cooling system solutions such as API Plan 11, 32, 52, and 53 based on customer requirements, ensuring long-term and reliable sealing performance.

Enviar un presupuesto rápido

Por qué más de 1.000 clientes confían en nosotros

Excelencia en ingeniería: precisión que rinde

Cada junta Sakowit está diseñada, mecanizada y probada para ofrecer la máxima fiabilidad y una larga vida útil, incluso en los entornos más exigentes.

Rendimiento probado: fiable en todos los sectores

Con la confianza de ingenieros de todo el mundo por su rendimiento constante en sistemas de procesos químicos, de lodos y de alta exigencia.

Asistencia mundial: respuesta rápida, servicio de confianza

Una red mundial y un servicio de asistencia con gran capacidad de respuesta le garantizan la ayuda de expertos cuando la necesite, esté donde esté.