Double Mechanical Seal Manufacturer

– Engineered for Reliability & Safety

Custom-engineered mechanical seals for slurry, mining, and dewatering pumps.Designed for long life in abrasive, high-solid, and high-pressure environments.

Why Choose Sakowitz as Your Double Mechanical Seal Manufacturer?

Sakowitz possesses over 20 years of experience in sealing technology R&D and manufacturing, establishing itself as a trusted Double Mechanical Seals manufacturer and supplier. We specialize in high-reliability sealing solutions. All products undergo precision machining, grinding, and leakage testing in our ISO-certified facilities, strictly adhering to API 682 / ISO 21049 international standards. Whether in chemical, pharmaceutical, petroleum, energy, or environmental industries, Sakowitz double mechanical seals earn global customer trust through exceptional pressure resistance, temperature tolerance, and extended service life.

Sakowitz not only offers standardized seal products but also provides customized designs tailored to specific pump types and media conditions. This includes diverse material combinations (SiC, TC, Carbon, FKM, FFKM) and barrier system configurations (Plan 52/53A/53B). We deliver comprehensive one-stop services—from design selection and on-site installation to after-sales technical support—ensuring each seal achieves safer, more efficient, and longer-lasting operational performance.

Double Mechanical Seal Product Series

As a professional double mechanical seal manufacturer, Sakowitz provides specialized custom solutions tailored to your specific application. Whether handling high-pressure fluids, corrosive solvents, or clean process media, Sakowitz’s double-ended mechanical seals deliver safer, more durable, and more efficient sealing solutions.

Póngase en contacto con nuestros especialistas en cierres mecánicos si tiene alguna pregunta

Póngase en contacto con nosotros y nuestro equipo profesional de Sakowit le ayudará a encontrar el cierre mecánico más adecuado para mejorar la seguridad de su proyecto.

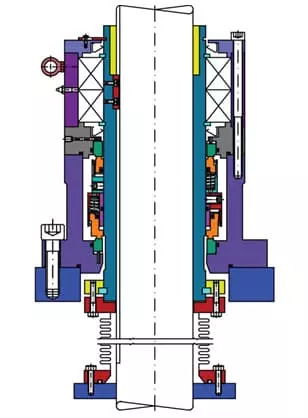

What is a Double Mechanical Seal?

Double Mechanical Seal is a high-performance sealing system composed of two sets of sealing faces. It is commonly used in industrial pumps and mixing equipment requiring leak prevention, high safety, or handling corrosive or volatile media.

It creates independent barrier chambers through inner and outer sealing faces, which can be filled with barrier fluid or gas to prevent medium leakage into the external environment. This ensures continuous, safe operation of equipment under high-pressure, high-temperature, or hazardous fluid conditions.

Compared to single-face seals, double mechanical seals offer higher sealing reliability and longer service life, making them an ideal choice for the chemical, petrochemical, pharmaceutical, energy, and environmental protection industries.

Key Features & Benefits of Slurry Pump Mechanical Seals

- Wear-resistant faces: SiC vs Tungsten Carbide combinations

- Heavy-duty springs: prevent clogging by solids

- Optional barrier / flush systems: API Plan 32, 54, 53A

- Self-cleaning design: avoids slurry build-up

- Long seal life: reduces downtime and maintenance costs

- Easy replacement: cartridge-style assembly for quick servicing

Even in highly abrasive environments, it delivers reliable sealing performance and reduces lifecycle costs.

Applications of Double Mechanical Seals

Double Mechanical Seals are widely used in industrial settings requiring high safety, leak prevention, or harsh operating conditions.

Transporting toxic, corrosive, or flammable media.

Ensuring hygienic, contamination-free production environments.

Suitable for high-temperature, high-pressure pump systems.

Handling liquids containing particles or corrosive substances.

Managing highly abrasive media such as slurries and muds.

Ensuring clean, leak-free operation of vacuum systems.

Double Mechanical Seal Working Principle

1️⃣ Primary Seal

The primary seal face is located on the process side, primarily preventing leakage of the pumped medium outside the seal chamber. It withstands process pressure and serves as the first line of defense in the sealing system.

2️⃣ Secondary Seal

The secondary seal face is located on the atmospheric side, preventing leakage of the barrier fluid or gas outward. It provides a second layer of protection in case of primary seal failure or wear.

3️⃣ Barrier Chamber

The cavity between the two seals is filled with liquid or gas barrier media:

- For liquid barriers, typically API Plan 52/53 systems, which circulate to cool the sealing surfaces;

- For gas barriers (e.g., nitrogen), Plan 74 systems are used for dry running or clean processes.

- The barrier medium pressure is typically maintained 1.5–2 bar higher than the pumped medium pressure to ensure no leakage to the external environment.

Frequently Asked Questions about Double Mechanical Seals

When should a double mechanical seal be used?

A: Double mechanical seals are recommended in the following situations:

- The medium is corrosive, toxic, or flammable;

- The system requires zero leakage or high vacuum operation;

- Operating conditions involve high temperatures, high pressures, or frequent pump starts;

- The medium contains solid particles or may crystallize.

What is the typical service life of a double-ended mechanical seal?

A: When properly installed and matched to operating conditions, Sakowitz seals achieve an average service life of 25,000–30,000 hours.

Regular inspection of shaft runout, barrier pressure, and cooling flow significantly extends service intervals.

Does Sakowitz offer customization and technical support?

A: Yes. Sakowitz provides customization for non-standard dimensions, material optimization design, and API system integration services.

Our engineering team delivers tailored sealing solutions based on pump models, media characteristics, and operating parameters, along with installation guidance and failure analysis support.

Enviar un presupuesto rápido

Por qué más de 1.000 clientes confían en nosotros

Excelencia en ingeniería: precisión que rinde

Cada junta Sakowit está diseñada, mecanizada y probada para ofrecer la máxima fiabilidad y una larga vida útil, incluso en los entornos más exigentes.

Rendimiento probado: fiable en todos los sectores

Con la confianza de ingenieros de todo el mundo por su rendimiento constante en sistemas de procesos químicos, de lodos y de alta exigencia.

Asistencia mundial: respuesta rápida, servicio de confianza

Una red mundial y un servicio de asistencia con gran capacidad de respuesta le garantizan la ayuda de expertos cuando la necesite, esté donde esté.