Mechanical Seal for Submersible Pump Manufacturer

– Sakowit designs and manufactures high-performance mechanical seals for submersible pumps.

Our seals ensure reliable underwater sealing, extended service life, and full compliance with ISO and API standards.

Understanding Mechanical Seals for Submersible Pumps

Submersible pumps operate in liquid for a long time. The reliability of the sealing system directly determines whether the motor is safe and whether the equipment has a long service life. Mechanical seals are the most crucial protective components in submersible pumps. They prevent liquid from seeping into the motor cavity through high-precision end face contact, thereby avoiding short circuits, corrosion and bearing failure. Compared with traditional packing or O-ring seals, mechanical seals can achieve higher sealing accuracy and stability. Research data shows that after using mechanical seals, the average operating life of submersible pumps can be increased by 2 to 3 times, and the maintenance frequency can be reduced by about 40%.

Why Submersible Pumps Need Reliable Mechanical Seals

Submersible pumps operate in liquid for long periods of time. Any minor leakage can lead to water ingress into the motor, short circuits or bearing damage. Mechanical seals are the key safety barrier to prevent liquids from seeping into the motor cavity. True zero-leakage operation is achieved through high-precision end face sealing and liquid film lubrication layers. Compared with traditional packing seals, mechanical seals have higher sealing accuracy and longer service life.

According to the test data:

- The average lifespan of submersible pumps equipped with mechanical seals is increased by 2 to 3 times.

- The maintenance frequency is reduced by 40 to 50%.

- The overall efficiency is improved by approximately 5 to 8%.

Póngase en contacto con nuestros especialistas en cierres mecánicos si tiene alguna pregunta

Póngase en contacto con nosotros y nuestro equipo profesional de Sakowit le ayudará a encontrar el cierre mecánico más adecuado para mejorar la seguridad de su proyecto.

Sakowit Engineering Solutions for Submersible Pump Mechanical Seals

Sakowit specializes in the precise design and manufacturing of mechanical seals for submersible pumps. Our products are specifically developed for deep water, high pressure and high wear environments, featuring a single end face, non-balanced structure, and combined with a rubber corrugated tube compensation system, which can effectively absorb axial displacement and vibration, maintaining stable sealing performance. All Sakowitz seals can be used in both directions and do not require distinguishing the installation direction, significantly enhancing installation convenience and versatility.

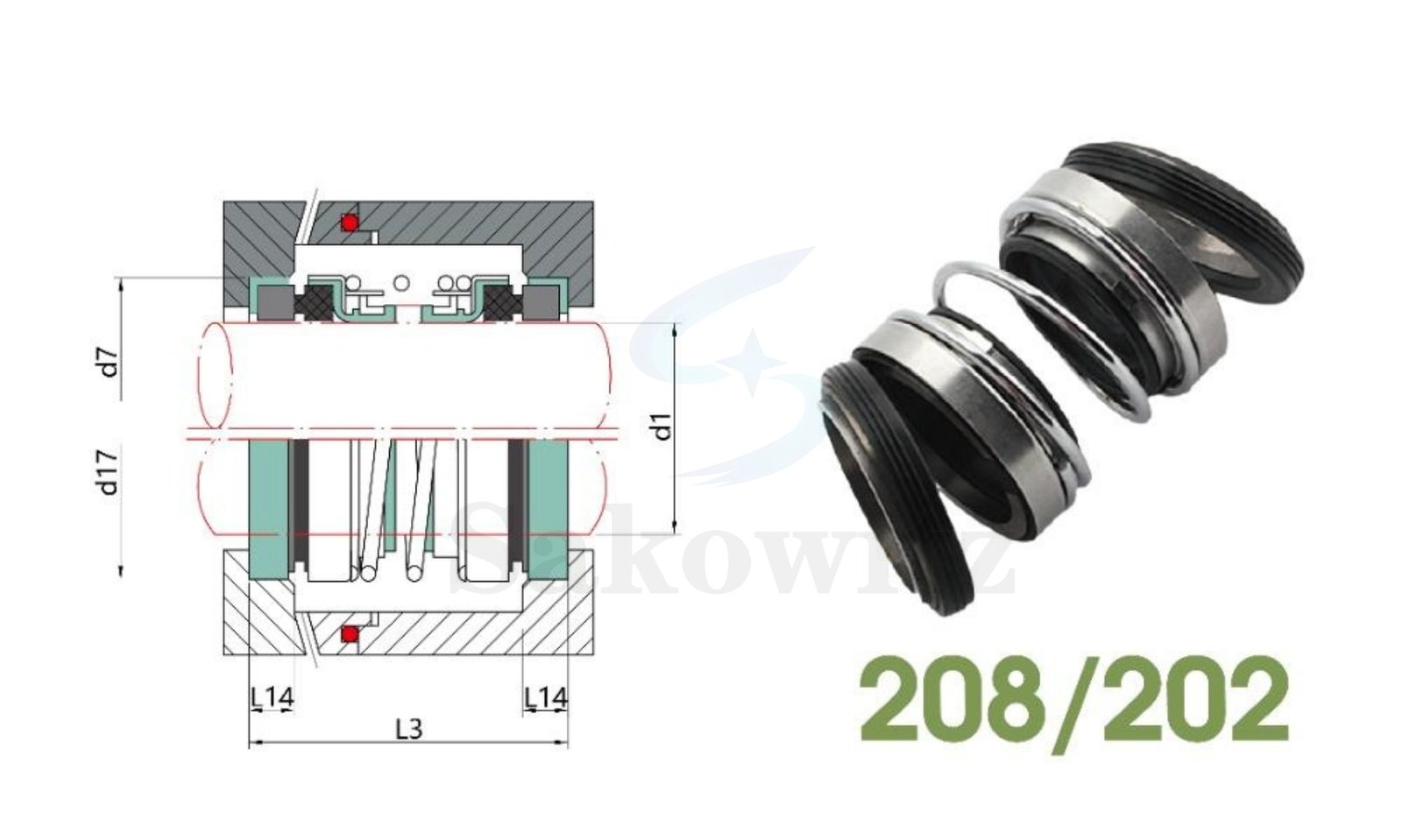

Some models (such as the 208/202 series) adopt a dual-sealing structure, consisting of two independent sealing combinations. They can be freely matched with different end face materials such as Carbon, SiC, TC, and are suitable for various working conditions including clear water, sewage, and light chemical processes.

The sealed metal components are made of SS304 / SS316, and the elastomers are selected from NBR, EPDM or Viton®. This ensures stable operation within the temperature range of -20°C to +80°C and pressure of 0.05–0.16 MPa. All products undergo pressure, wear resistance and immersion tests before leaving the factory, with a cumulative test duration exceeding 5000 hours, guaranteeing long-term underwater reliability.

Key Technical Specifications

The mechanical seal of the Sakowit submersible pump is made of a combination of high-strength silicon carbide, carbon graphite and tungsten carbide materials, ensuring stable sealing under high pressure (up to 1.6 bar), temperature fluctuations (-20 to 80°C) and continuous operation (3000 rpm) conditions. The stainless steel 304/316 springs and metal components provide excellent corrosion resistance, and the elastomer materials (NBR, EPDM, Viton®) are suitable for clean water, sewage and light chemical media.

| Component / Parameter | Material / Range | Description & Engineering Insight |

|---|---|---|

| Rotary Ring Face | Carbon / Silicon Carbide (SiC) / Tungsten Carbide (TC) | Hard, wear-resistant materials for rotating faces. SiC and TC ensure long service life under abrasive water. |

| Stationary Ring Face | Carbon / SiC / TC | Provides smooth, tight sealing against the rotary face. Excellent heat dissipation under load. |

| Elastomers (Secondary Seals) | NBR / EPDM / FKM (Viton®) | Resistant to water, oil, and chemical degradation. Suitable for long-term submersion. |

| Metal Parts | Stainless Steel 304 / 316 | Corrosion-resistant structure for freshwater and seawater environments. |

| Springs | Stainless Steel 304 / 316 | Ensures constant face pressure and automatic wear compensation. |

| Operating Pressure | 0.05 – 0.16 MPa (0.5 – 1.6 bar) | Optimized for submersible pump chamber balance. Prevents leakage under backpressure. |

| Temperatura de funcionamiento | -20°C to +80°C | Suitable for cold water, sewage, and mild chemical environments. |

| Linear Speed | Up to 3000 rpm | Maintains stability under standard motor shaft speeds. |

| Testing Standards | ISO 21049 / API 682 / CE | Each seal undergoes vacuum, pressure, and endurance testing before shipment. |

Key Industries and Applications for Submersible Pump Mechanical Seals

Sakowit submersible pump mechanical seals are widely used in water treatment, mining, petrochemicals, maritime, agricultural and construction projects. Our sealing design can maintain long-term stable operation in complex media with high pressure, abrasion and corrosion, ensuring system safety, reducing maintenance and extending the service life of the pump.

For sewage pumps, drainage pumps and irrigation systems. Mechanical seals prevent sewage or solid particles from entering the motor cavity, ensuring long-term stable operation of the pump system.

When conveying abrasive media such as slurry or ore pulp, SiC/TC hard-faced materials are employed. The wear-resistant construction significantly extends seal service life and reduces maintenance costs.

For use in deep well submersible pumps and downhole oil-water separation systems. Sakowitz seals withstand high pressure and temperature, preventing oil and gas leakage.

Suitable for bilge pumps, ballast pumps and cooling water systems. Constructed from stainless steel 316 and salt-spray resistant elastomer materials, providing effective corrosion protection.

For agricultural submersible pumps and sprinkler irrigation systems. The sealing structure prevents abrasion of the end faces by silt and particulate matter, ensuring stable water flow.

Widely employed in foundation pit drainage and groundwater control systems. The pressure-resistant sealed structure maintains stability under prolonged immersion and vibration conditions.

Why Engineers Worldwide Choose Sakowitz Mechanical Seals

Choosing Sakowit means choosing proven reliability and engineering accuracy. Our submersible pump mechanical seals have successfully operated in projects in over 40 countries, with installation quantities exceeding 10,000 units, and have demonstrated outstanding performance in real working conditions.

Sakowit employs advanced CNC precision processing technology, ensuring that the flatness of each pair of sealing end faces is controlled at menos de 2 micrómetros, guaranteeing perfect fit and zero leakage even under high pressure and high speed conditions. All materials are rigorously selected and include silicon carbide, tungsten carbide, stainless steel 316, and Viton® elastomer. It boasts excellent corrosion resistance and wear resistance, suitable for complex environments such as sewage, seawater, and chemical media.

Sakowit also offers global OEM compatibility support and technical response. Whether it’s the modification of submersible pumps, OEM integration, or on-site maintenance, our engineering team can respond promptly and provide matching solutions.

Frequently Asked Questions about Mechanical Seal for Submersible Pump

Q1: Can Sakowit seals replace my existing submersible pump seal?

Yes. Sakowit offers alternative designs compatible with most international pump brands and can also customize production according to actual dimensions and media.

Q2: What is the typical service life underwater?

Under normal working conditions, the service life is usually 2 to 5 years. The lifespan depends on the type of liquid, temperature, pressure and maintenance frequency.

Q3: Are Sakowit seals suitable for seawater or corrosive environments?

Certainly. We utilise duplex stainless steel and Hastelloy materials, which offer outstanding corrosion resistance and are suitable for marine and chemical environments.

Q4: Can Sakowitz seals be used in oil-filled submersible motors?

Certainly. We offer a dual-end seal design specifically engineered for oil lubrication systems, ensuring complete isolation between the oil chamber and external media.

Q5: Do you provide installation or maintenance support?

Our engineering team can provide remote guidance for installation, leak testing and seal maintenance, ensuring customers achieve optimal performance.

Enviar un presupuesto rápido

Por qué más de 1.000 clientes confían en nosotros

Excelencia en ingeniería: precisión que rinde

Cada junta Sakowit está diseñada, mecanizada y probada para ofrecer la máxima fiabilidad y una larga vida útil, incluso en los entornos más exigentes.

Rendimiento probado: fiable en todos los sectores

Con la confianza de ingenieros de todo el mundo por su rendimiento constante en sistemas de procesos químicos, de lodos y de alta exigencia.

Asistencia mundial: respuesta rápida, servicio de confianza

Una red mundial y un servicio de asistencia con gran capacidad de respuesta le garantizan la ayuda de expertos cuando la necesite, esté donde esté.