Premature mechanical seal failure is one of the most frustrating issues in industrial pump operation.

When a seal fails far earlier than expected, the first reaction is often to blame product quality. However, in most cases, early seal failure is not caused by the seal itself.

Understanding why mechanical seals fail prematurely requires looking beyond the seal and examining the entire pump system, operating conditions, and installation practices.

Premature Seal Failure Is Rarely a Random Event

Mechanical seals are engineered components designed to operate under specific conditions. When a seal fails early, it is usually responding to stress factors that exceed its design limits.

In other words, premature failure is typically a symptom, not the root problem.

Identifying the real cause is essential to prevent repeated failures and unnecessary replacement costs.

Common Reasons Mechanical Seals Fail Prematurely

Operating Conditions That Exceed Design Limits

One of the most common causes of early seal failure is operating outside the assumed conditions used during seal selection.

Unexpected pressure spikes, temperature fluctuations, or dry-running events can quickly damage seal faces and secondary sealing elements. Even brief deviations from normal operation may significantly shorten seal life.

In many cases, the actual operating environment is more severe than the data originally provided.

Poor Shaft Alignment and Excessive Vibration

Mechanical seals rely on stable shaft movement to maintain a consistent sealing interface. Misalignment, worn bearings, or imbalance can introduce vibration that accelerates face wear and leads to leakage.

Seal failures caused by vibration are often misdiagnosed as material or design problems, when the true issue lies within the pump or driver system.

Improper Installation Practices

Incorrect installation remains a leading contributor to premature mechanical seal failure.

Common installation-related issues include contamination during assembly, incorrect setting length, uneven tightening, or failure to follow recommended procedures. Even small installation errors can result in rapid seal degradation.

A properly designed seal cannot compensate for poor installation quality.

Incomplete or Inaccurate Operating Data During Selection

Seal selection based only on pump nameplate data often ignores real-world conditions such as startup behavior, intermittent operation, or fluid variations.

Missing information during the selection process increases the likelihood of choosing a seal that is unsuitable for actual service conditions, leading to early failure despite correct installation.

Fluid-Related Challenges

The properties of the pumped fluid play a critical role in seal performance. Solids contamination, crystallization, poor lubricity, or chemical incompatibility can all damage sealing surfaces.

Even fluids that appear benign under normal conditions may become aggressive as temperature or concentration changes.

Why Replacing the Seal Alone Often Fails to Solve the Problem

When a seal fails prematurely, replacing it with the same design without addressing underlying issues frequently leads to repeated failures.

This cycle occurs because the original root cause—such as vibration, dry running, or unstable operation—remains uncorrected. As a result, each new seal experiences the same damaging conditions.

Effective troubleshooting requires evaluating the pump system as a whole rather than focusing solely on the seal.

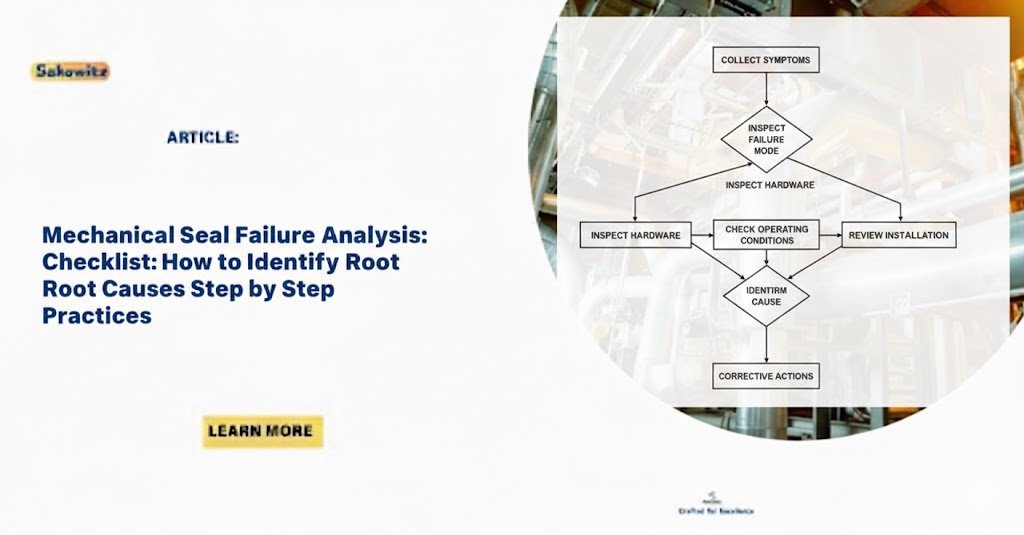

How to Identify the Root Cause of Premature Seal Failure

Accurate failure analysis begins with examining operating history, maintenance records, and system behavior.

Key questions include:

-

Were there recent changes in operating conditions?

-

Has vibration or noise increased over time?

-

Did the failure occur shortly after installation or startup?

-

Are there signs of heat damage, scoring, or uneven wear?

Combining physical inspection with system-level analysis helps distinguish between seal-related issues and external contributors.

How to Prevent Premature Mechanical Seal Failure

While not all failures are avoidable, many premature seal failures can be prevented through systematic improvements.

Improve Data Accuracy During Seal Selection

Providing complete and realistic operating data—including transient conditions—allows for more appropriate seal design and material selection.

Address System-Level Mechanical Issues

Ensuring proper shaft alignment, stable bearing condition, and controlled vibration protects seals from unnecessary stress.

Follow Proper Installation and Maintenance Procedures

Clean assembly environments, correct setting procedures, and routine inspections significantly improve seal reliability and service life.

Final Thoughts: Premature Seal Failure Is a System Problem

Mechanical seals rarely fail prematurely without reason. In most cases, early failure is the result of operating conditions, mechanical issues, or installation errors rather than product defects.

Understanding and addressing these underlying factors not only extends seal service life but also improves overall pump reliability and reduces unplanned downtime.

Instead of repeatedly replacing seals, focusing on the entire pump system delivers far better long-term results.

👉https://sakowit.com/top-10-mechanical-seal-problems-and-their-solutions-complete-guide/