Mechanical seals are designed to keep pumps, mixers, agitators, and compressors running safely and efficiently.

Mechanical seals are designed to keep pumps, mixers, agitators, and compressors running safely and efficiently.

But even the best seal can fail prematurely if application conditions are not properly managed.

To help prevent downtime, leakage, and equipment damage, here are the 10 most common mechanical seal problems—and the exact solutions engineers should apply.

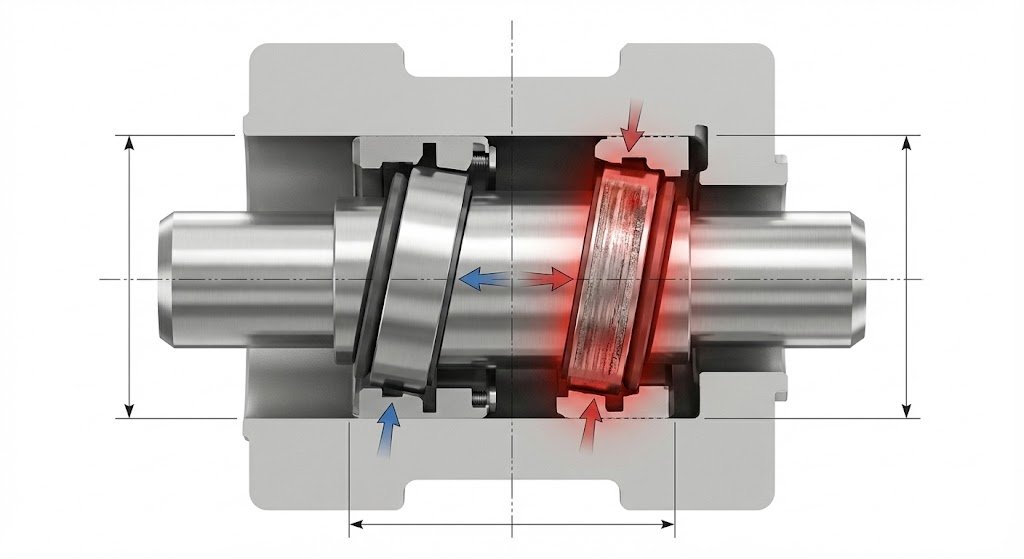

1. Dry Running (No Lubrication)

When the seal faces run without lubrication from the pumped medium, friction rapidly destroys the carbon, SIC, or ceramic faces.

How to Identify

-

Loud squealing noise

-

Rapid temperature rise

-

Seal face burned or cracked

الحل

✔ Prime the pump before startup

✔ Install flow/pressure sensors to prevent operation without liquid

✔ Consider cartridge seals with cooling jackets for high-risk systems

2. التركيب غير السليم

Incorrect alignment, over-tightening, and contamination during installation are among the top causes of seal failure.

Signs

-

Early leakage immediately after startup

-

Excessive wear on one side of the seal face

الحل

✔ Always follow manufacturer instructions

✔ Use trained technicians only

✔ Choose pre-assembled cartridge seals (like Sakowitz M481K) to minimize installation errors

3. عدم التوافق الكيميائي

Wrong material selection leads to corrosion, swelling, or face degradation.

Common Mistakes

-

Using Viton where EPDM or FFKM is required

-

Selecting carbon faces in strong oxidizers

الحل

✔ Match O-rings and faces to chemical properties

✔ For aggressive media, select SIC/SIC or TC/TC face combinations

✔ Use our material selection guide (内链)

4. الاهتزاز المفرط

Misalignment, cavitation, or imbalance increases vibration—causing seal faces to open momentarily and leak.

الحل

✔ Check alignment regularly

✔ Fix foundation looseness

✔ Install vibration sensors for continuous monitoring

5. Incorrect Seal Type Selection

Using a single spring seal in an application that requires a double seal is a common problem.

الحل

✔ Define pressure, temperature, and media clearly

✔ Choose double mechanical seals for hazardous or abrasive media

✔ For high-pressure reactors, choose M481K cartridge seals

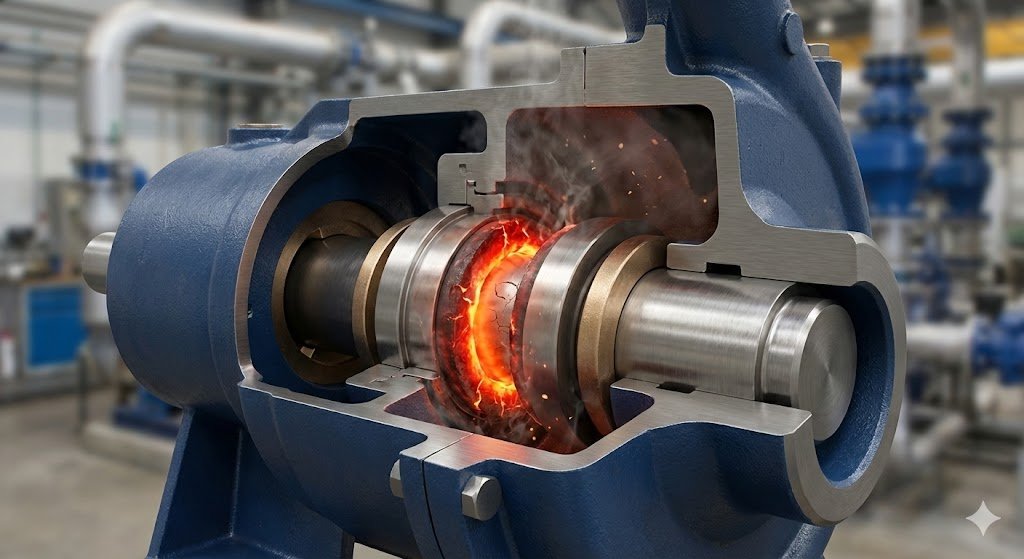

6. Thermal Shock or Overheating

Temperature rises beyond the material limit can crack seal faces.

Typical Causes

-

Cooling water interruption

-

Pump running at very low flow

الحل

✔ Use SIC or TC faces rated for high-temperature

✔ Maintain minimum flow

✔ Add API flush plans (Plan 11, Plan 21, Plan 32)

7. Poor Lubrication Film (Dry Gas Layer)

Some fluids provide weak lubrication film—leading to face scoring.

الحل

✔ Introduce a compatible flush fluid

✔ Use hydropad/hydrostatic seal faces

✔ Upgrade to a cartridge seal with enhanced lubrication channels

8. Product Build-Up on Seal Faces

Crystals, polymers, or sticky media cause uneven seal wear.

الحل

✔ Use Plan 32 or Plan 62 flushing

✔ Select hard-hard face combinations

✔ Consider external pressurized barrier fluid

9. Shaft Movement or Misalignment

Axial or radial movement pushes the seal faces apart.

الحل

✔ Inspect bearings regularly

✔ Ensure shaft runout is within tolerance

✔ Use a seal with a compensated design (bellows or cartridge)

10. Poor Seal Storage & Handling

Even before installation, seals can be damaged.

الحل

✔ Store seals in dry, cool environments

✔ Keep O-rings from ozone exposure

✔ Inspect seals right before installation

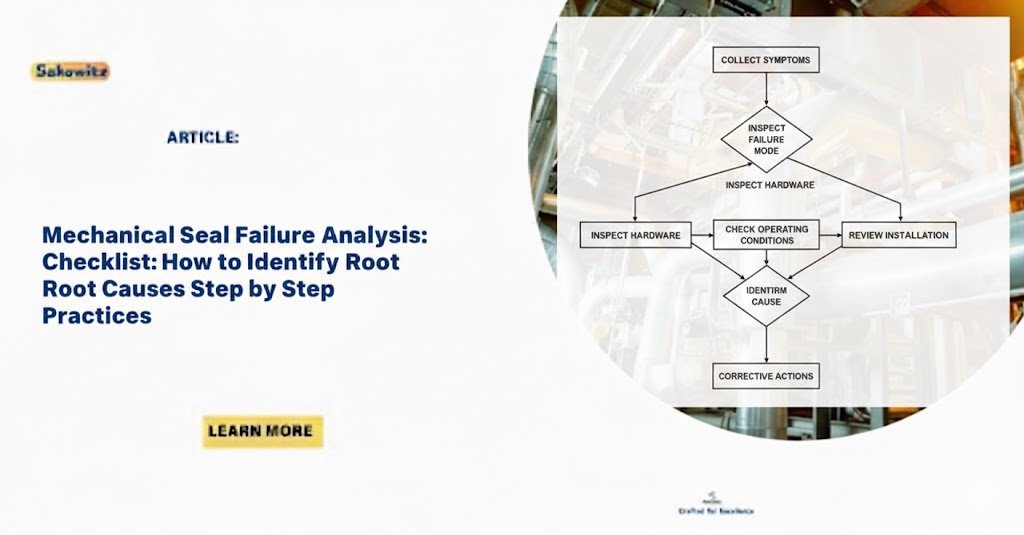

When to Upgrade Your Mechanical Seals

If your process involves:

-

الضغط العالي

-

High temperature

-

Abrasive media

-

Corrosive chemicals

-

CIP/SIP sterilization (制药)

Then consider upgrading to:

➡ Sakowitz Cartridge Mechanical Seals

-

Pre-assembled (avoid installation errors)

-

Suitable for 200°C+ conditions

-

Available in SIC/SIC, TC/TC, SIC/Carbon

-

Long service life and predictable maintenance

-

https://sakowit.com/rubber-bellow-mechanical-seal-manufacturer/