Introduction: Why API Flush Plans Are Critical for Seal Reliability

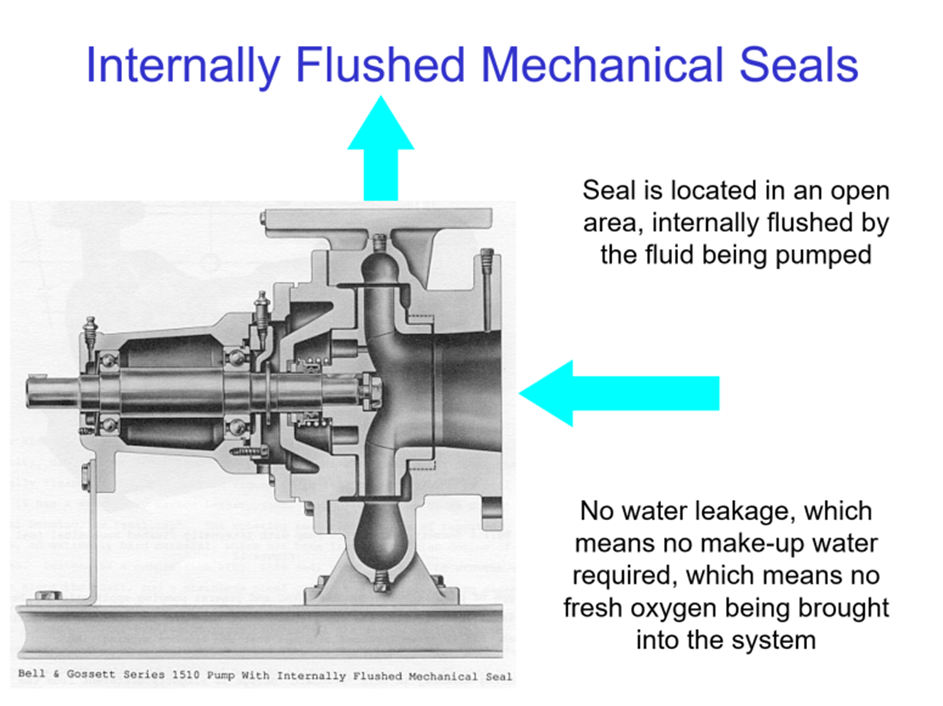

Mechanical seal failures are often caused not by the seal design itself, but by insufficient cooling, poor lubrication, or improper flush configuration.

This is where API Flush Plans play a critical role.

API flush plans define how fluids are supplied, circulated, or removed around the mechanical seal to control temperature, remove heat, prevent dry running, and reduce leakage.

This article explains the most commonly used API Flush Plans, how they work, and which flush plan best prevents leakage and overheating in different pump applications.

What Is an API Flush Plan?

An API flush plan is a standardized piping and instrumentation arrangement defined by API (American Petroleum Institute).

It specifies how seal chambers are flushed, quenched, or cooled to ensure stable mechanical seal operation.

Main Objectives of API Flush Plans:

-

Remove heat from seal faces

-

Maintain proper lubrication

-

Prevent vaporization and dry running

-

Reduce seal leakage

-

Improve seal life and reliability

API Plan 11 – The Most Common Flush Plan

كيف تعمل

-

Takes clean process fluid from pump discharge

-

Flushes directly into the seal chamber

Advantages

-

Simple and cost-effective

-

No external equipment required

-

Widely used in clean services

Limitations

-

Not suitable for dirty or abrasive fluids

-

Limited cooling capability

Typical Applications

-

Clean hydrocarbons

-

Water and light chemicals

👉 Best for: Basic cooling, low risk of solids

👉 Leakage control: Limited

👉 Overheating prevention: Moderate

API Plan 21 – Improved Cooling for Hot Fluids

كيف تعمل

-

Similar to Plan 11

-

Includes a cooler before entering the seal chamber

Advantages

-

Better heat removal

-

Suitable for higher temperature services

Limitations

-

Still uses process fluid

-

Risk of fouling if fluid is dirty

👉 Best for: Hot but clean fluids

👉 Overheating prevention: Good

👉 Leakage control: Limited

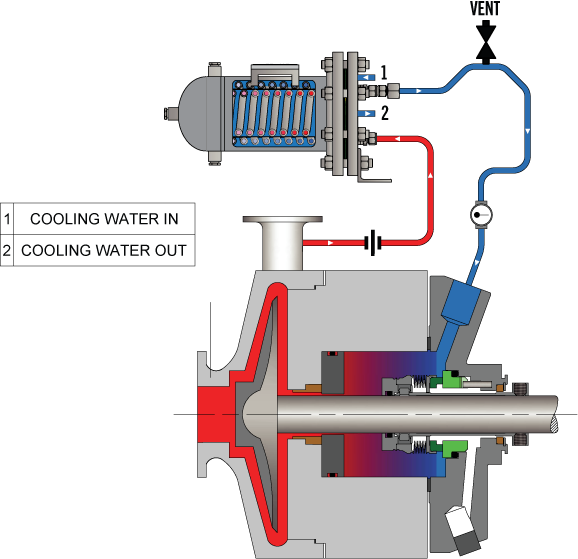

API Plan 23 – The Best Plan for Overheating Prevention

كيف تعمل

-

Circulates fluid within the seal chamber

-

External cooler removes heat efficiently

Advantages

-

Excellent heat removal

-

Reduces seal face temperature significantly

-

Improves seal life

Limitations

-

More complex piping

-

Higher cost

👉 Best for: Preventing seal overheating

👉 Leakage control: Moderate

👉 Recommended for: High-speed or high-temperature pumps

API Plan 32 – External Flush for Dirty or Crystallizing Fluids

كيف تعمل

-

Uses an external clean flush fluid

-

Flush pressure higher than seal chamber pressure

Advantages

-

Prevents solids from entering seal chamber

-

Keeps seal faces clean

-

Reduces wear and leakage

Limitations

-

Requires external fluid source

-

Dilutes process fluid

👉 Best for: Dirty, abrasive, or crystallizing fluids

👉 Leakage prevention: Very good

👉 Overheating prevention: Good

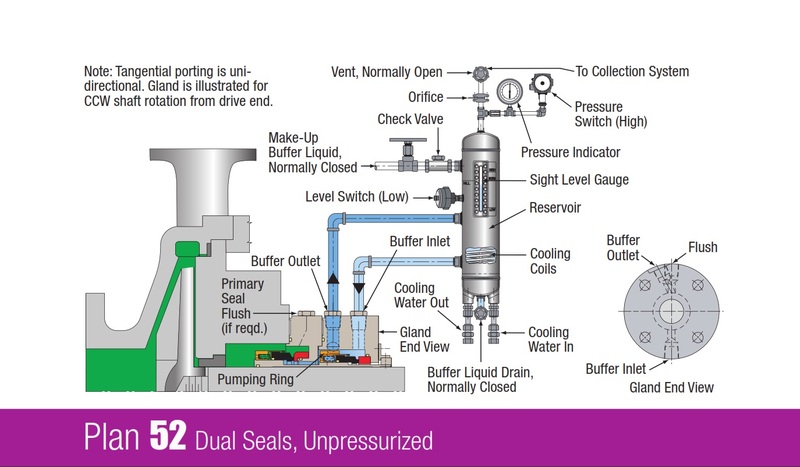

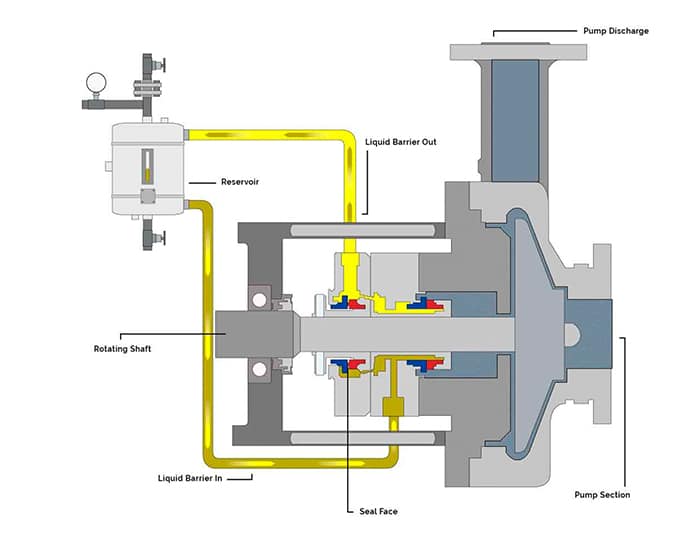

API Plan 52 – Buffer Fluid for Double Seals

كيف تعمل

-

Uses buffer fluid at lower pressure than process

-

Leakage flows into buffer fluid chamber

Advantages

-

Reduces emissions

-

Allows leakage monitoring

-

Lower complexity than barrier systems

Limitations

-

Does not fully isolate process fluid

👉 Best for: Moderate leakage control

👉 Overheating prevention: Moderate

API Plan 53 – Barrier Fluid for Maximum Leakage Prevention

كيف تعمل

-

Uses pressurized barrier fluid

-

Barrier fluid pressure higher than process pressure

Advantages

-

Maximum leakage prevention

-

Excellent seal face lubrication

-

High safety level

Limitations

-

Higher cost

-

Requires pressure control system

👉 Best for: Preventing leakage

👉 Overheating prevention: Excellent

👉 Recommended for: Hazardous and toxic media

Which API Flush Plan Prevents Leakage and Overheating Best?

| Objective | Recommended API Plan |

|---|---|

| Prevent Overheating | API Plan 23 |

| Prevent Leakage | API Plan 53 |

| Dirty or Abrasive Media | API Plan 32 |

| Simple Clean Service | API Plan 11 |

| Emission Reduction | API Plan 52 |

In many critical applications, API Plan 23 + Double Seal provides the best balance between cooling and reliability.

Common Mistakes in API Flush Plan Selection

-

Using Plan 11 in dirty services

-

Ignoring heat load at high speed

-

Insufficient flush pressure

-

Poor cooler sizing

These mistakes often result in seal face cracking, vaporization, and premature leakage.

FAQ: API Flush Plans

Q1: Is API Plan 23 always better than Plan 11?

For high-temperature or high-speed applications, yes. For simple clean services, Plan 11 may be sufficient.

Q2: Can API Plan 32 replace a double seal?

No. Plan 32 improves cleanliness but does not replace the safety of a double seal.

Q3: Do all double seals require API Plan 53?

Not always. Plan 52 is acceptable for lower-risk applications.

Final Thoughts: Flush Plan Selection Is a Thermal Management Decision

API flush plans are not optional accessories—they are thermal and leakage control systems. Selecting the correct plan can dramatically reduce seal failures, leakage incidents, and maintenance costs.

Understanding process fluid, temperature, pressure, and solids content is essential before choosing an API flush plan.

Call to Action (CTA)

👉 Need help selecting the right API flush plan for your mechanical seal?

Share your pump conditions and process data. Our technical team can recommend the most suitable API flush plan to prevent leakage and overheating.

👉https://sakowit.com/how-to-replace-oem-mechanical-seals-without-changing-pump-design/