Introduction: Why Seal Support Systems Matter

Mechanical seal performance does not depend on the seal alone.

In many industrial pump applications, seal support systems play a critical role in controlling temperature, lubrication, leakage, and safety.

Understanding the difference between single seal systems, double seal systems, barrier fluids, and buffer fluids is essential for choosing the right configuration—especially when handling hazardous, abrasive, or high-temperature fluids.

This guide explains how seal support systems work and how to choose the right option for your application.

Overview: Single Seal vs Double Seal Systems

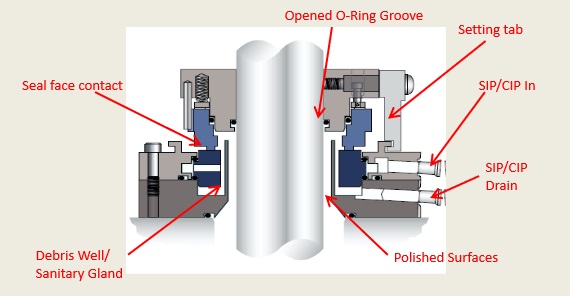

Mechanical seals are typically configured as single seals أو double seals, depending on the process requirements.

Single Mechanical Seal System

-

One set of seal faces

-

Process fluid is directly sealed

-

Simple design, lower cost

Double Mechanical Seal System

-

Two sets of seal faces

-

Seal chamber isolated from process fluid

-

Requires external support fluid

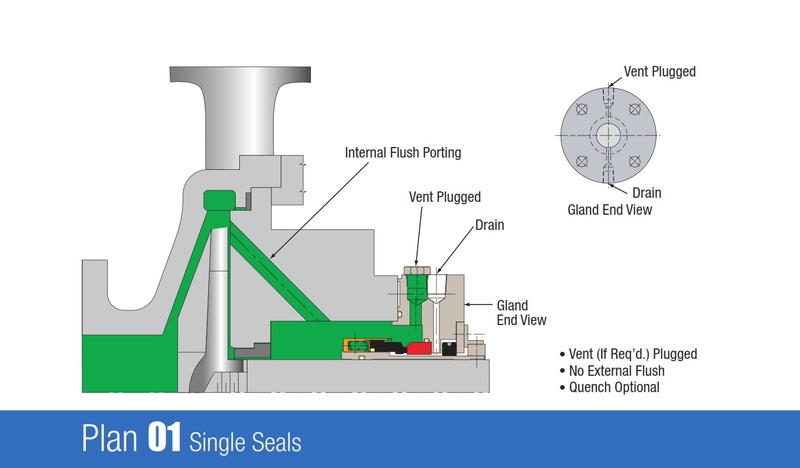

Single Seal Support Systems

Single seals are commonly used with flush or quench systems to improve lubrication and cooling.

Typical Characteristics

-

Uses process fluid or external flush

-

Limited leakage control

-

Lower installation and maintenance cost

Common Applications

-

Clean water pumps

-

Non-hazardous fluids

-

Low to moderate pressure systems

Single seal systems are not recommended for toxic, abrasive, or volatile media where leakage control is critical.

Double Mechanical Seal Support Systems

Double seal systems provide enhanced safety and reliability by isolating the process fluid from the atmosphere.

There are two main types of double seal support systems:

-

Barrier Fluid Systems

-

Buffer Fluid Systems

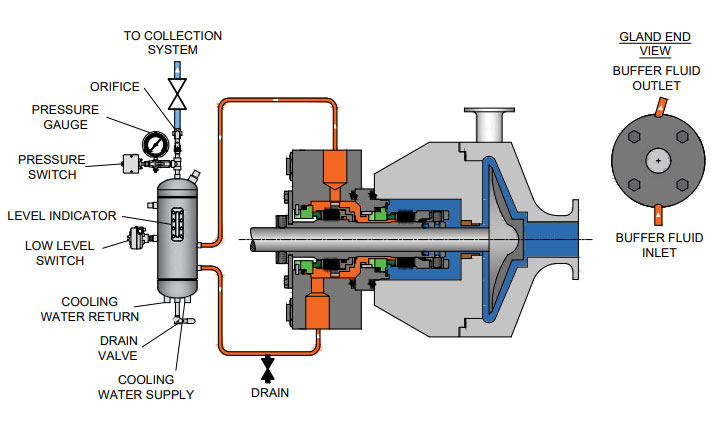

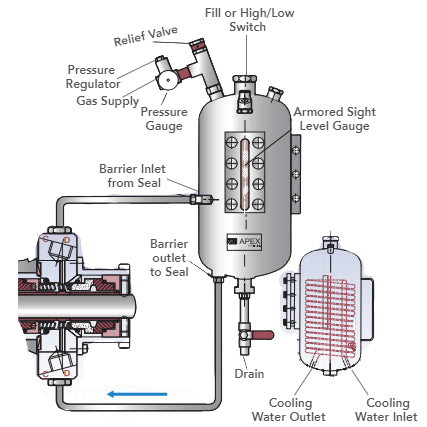

What Is a Barrier Fluid System?

Definition

A barrier fluid is a clean fluid maintained at a pressure higher than the process pressure.

This ensures that any leakage flows into the process, not outward.

Key Features

-

Fully isolates process fluid

-

Prevents leakage to atmosphere

-

Requires pressure control system

Advantages

-

Maximum safety

-

Excellent for hazardous or toxic media

-

Improved seal face life

Typical Applications

-

Chemical processing

-

Oil & gas

-

Toxic, flammable, or high-value fluids

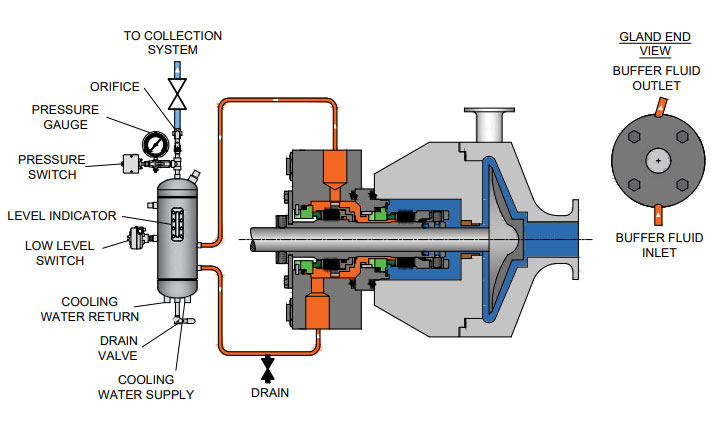

What Is a Buffer Fluid System?

Definition

A buffer fluid operates at a pressure lower than the process pressure.

Any leakage flows into the buffer fluid chamber, not into the process.

Key Features

-

Reduces emissions

-

Lower system complexity

-

Does not fully isolate process fluid

Advantages

-

Lower cost than barrier systems

-

Reduced leakage to atmosphere

-

Simpler operation

Typical Applications

-

Mildly hazardous fluids

-

Applications requiring leakage monitoring

-

Moderate safety requirements

Barrier Fluid vs Buffer Fluid: Key Differences

| Feature | Barrier Fluid | Buffer Fluid |

|---|---|---|

| Pressure Level | Higher than process | Lower than process |

| Leakage Direction | Into process | From process into buffer |

| Safety Level | Very high | Medium |

| System Complexity | Higher | Lower |

| Typical API Plans | Plan 53 / 54 | Plan 52 |

How to Choose the Right Seal Support System

Choosing the correct support system depends on process risk, operating conditions, and safety requirements.

Selection Guidelines:

-

Non-hazardous, clean fluid → Single seal

-

Mild leakage concern → Double seal with buffer fluid

-

Toxic, flammable, or dangerous media → Double seal with barrier fluid

-

Strict environmental or safety regulations → Barrier fluid system

When safety or compliance is involved, double seals with barrier fluids are the industry standard.

Common Mistakes in Seal Support System Selection

-

Using single seals in hazardous media

-

Incorrect barrier fluid pressure control

-

Poor fluid compatibility

-

Neglecting heat removal requirements

Avoiding these mistakes significantly reduces seal failures and safety incidents.

FAQ: Seal Support Systems

Q1: Is a double seal always better than a single seal?

Not always. Double seals increase cost and complexity. They should be used when safety or reliability requires it.

Q2: Can barrier and buffer fluids be the same liquid?

Sometimes, but fluid compatibility and pressure requirements must be carefully evaluated.

Q3: Do double seals eliminate leakage completely?

They greatly reduce emissions but do not guarantee zero leakage.

Final Thoughts: Safety and Reliability Drive the Choice

Seal support systems are not optional accessories—they are an integral part of mechanical seal performance. Choosing between single seals, buffer fluids, and barrier fluids should be based on process risk, safety standards, and operating conditions, not cost alone.

A properly selected support system protects both equipment and personnel.

Call to Action (CTA)

👉 Need help choosing a seal support system for your pump?

Share your process fluid, pressure, and safety requirements. Our technical team can recommend the most suitable single or double seal configuration with the correct support system.

👉https://sakowit.com/how-operating-conditions-affect-mechanical-seal-performance-in-industrial-pumps/