Agitator Mechanical Seal Manufacturer

– Providing high-performance sealing solutions for agitators, reactors and mixing equipment.

Effectively prevent the leakage of liquids or gases to ensure the safe and stable operation of processes in chemical engineering, pharmaceuticals, food and other industries.

Agitator Mechanical Seals – Definition & Working Principle

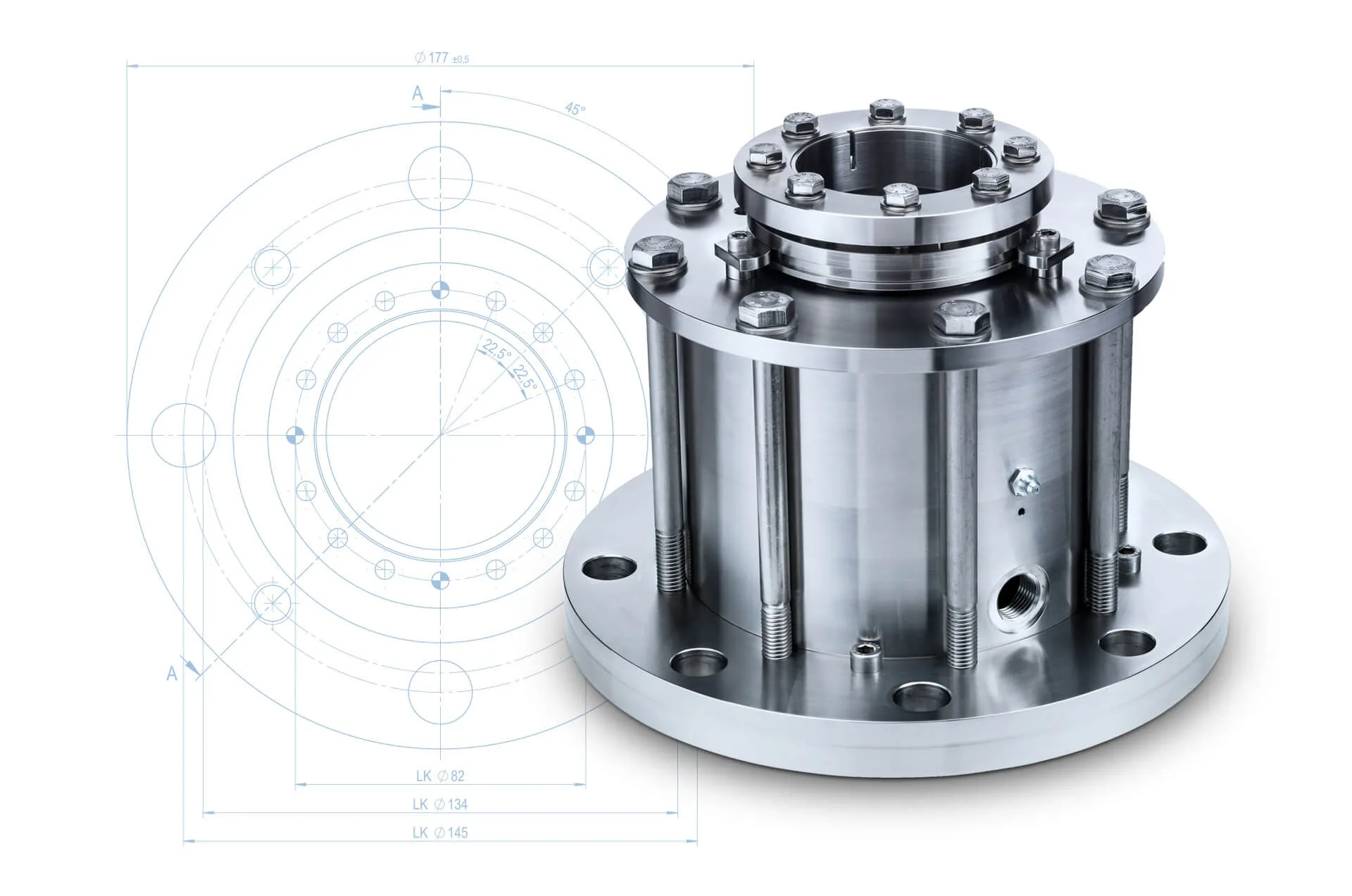

Agitator Mechanical Seal (Mechanical Seal for Stirring Equipment and Reactor Shaft Seals) is a high-performance sealing component specifically designed for use in stirring equipment and reactor shaft sealing systems. It prevents medium leakage through the micro-lubricating film formed between the moving ring and the stationary ring, ensuring system stability under high-speed rotation or high-pressure reaction conditions.

Unlike the common pump seals, the Agitator Mechanical Seal can handle axial displacement, radial runout, and the vibrations generated by the agitation process. Its structure is more robust and can operate for long periods under vacuum, positive pressure, or high-temperature conditions. Usually, this type of agitator seal system is made of corrosion-resistant materials and is combined with high-performance elastomers (such as FKM or PTFE) to ensure long-lasting and reliable sealing performance.

Benefits of Using Agitator Mechanical Seals in Mixing Systems

Agitator Mechanical Seal can effectively prevent liquid leakage and gas evaporation, ensuring the safety and stability of the reaction process. Additionally, it has a self-adjusting compensation function, which can absorb the slight displacement and vibration of the stirring shaft, thereby enhancing the overall reliability of the equipment.

Compared with traditional sealing methods, mechanical seals can significantly reduce maintenance frequency and energy consumption. According to industry statistics, the use of mechanical seals in mixing systems can reduce the risk of leakage by more than 85%, and extend the service life of the equipment by 30%.

Under complex process conditions, such as mixing, distillation, polymerization or reaction processes, the Agitator Mechanical Seal offers a stable sealing effect, helping enterprises achieve safe production and energy-saving operation.

Agitator Mechanical Seals Product Series

Contact Our Mechanical Seal Specialists for Questions

Contact us, and our professional Sakowit team can help you find the most suitable mechanical seal to enhance the safety of your project.

Sakowitz Agitator Mechanical Seal Solutions

Sakowitz, as a professional Agitator Mechanical Seal Manufacturer, focuses on providing high-performance sealing solutions for the chemical, pharmaceutical and food industries. Our products are precisely designed according to different working conditions to ensure stable sealing under high pressure, vacuum and corrosive media.

Sakowitz offers various structural types, including single-end, double-end, dry-flow transformation and cooling jacket types, to meet the requirements of different mixing processes. All seals are made of high-strength materials such as SiC, tungsten carbide, carbon graphite, and are combined with elastomers like PTFE, FKM, possessing both chemical resistance and wear resistance.

The metal components are made of materials such as SS316, Duplex, Hastelloy®, Titanium, etc., which can effectively resist acid and alkali corrosion as well as high-temperature environments.

The products all comply with international standards such as API 682, ISO 21049, CE, FDA, ATEX, and can be seamlessly integrated with equipment such as reaction tanks, mixers, blending tanks and vacuum kettles.

Technical Performance of Sakowitz Agitator Mechanical Seals

Sakowitz’s Agitator Mechanical Seal is precisely designed to maintain excellent sealing performance in high-temperature, high-pressure and highly corrosive environments. Its structure is stable and highly adaptable, capable of meeting a wide range of application requirements from chemical reaction vessels to food mixing tanks.

| Parameter | Specification / Range | Description |

|---|---|---|

| Pressure | ≤ 25 bar | Suitable for high-pressure reactors and vacuum systems. |

| Temperature | -40°C ~ +250°C | Designed for extreme hot and cold temperature conditions. |

| Speed | ≤ 20 m/s | Ideal for medium- to high-speed agitator shafts. |

| Face Materials | SiC / WC / Carbon | Provides excellent wear and chemical resistance. |

| Elastomers | FKM / FFKM / PTFE / EPDM | Ensures corrosion resistance and food-grade compliance. |

| Metals | SS316 / Duplex / Hastelloy® | High-strength materials for superior corrosion protection. |

| Compliance | API 682 / ISO 21049 / CE / FDA | Meets international engineering and safety standards. |

| Applications | Reactors, Agitators, Mixers, Blenders | Ideal for chemical, food, and pharmaceutical process systems. |

Industrial Applications of Agitator Mechanical Seals

Used for reaction vessels, stirring reaction systems and chemical mixing equipment. It can resist corrosive media such as acids, alkalis and organic solvents, ensuring long-term stable operation.

Made of materials that meet FDA and GMP requirements, it is suitable for sterile, vacuum and high-purity production environments, and meets the strict hygiene standards of pharmaceutical manufacturing.

Widely applied in stirring systems for dairy products, syrups, sauces, etc. Food-grade sealing materials prevent contamination and ensure production safety and equipment hygiene.

Particularly suitable for high-viscosity emulsification and vacuum mixing equipment. The sealing structure withstands shear forces and temperature fluctuations, maintaining uniform mixing results.

Used in aseptic processes such as fermentation tanks and bioreactors to ensure the system’s airtightness and anti-contamination performance, meeting the production requirements of biological products.

It is applicable to sludge treatment, wastewater stirring and new energy reaction equipment. The corrosion-resistant design extends the operational life and reduces maintenance costs.

Why Choose Sakowitz as Your Agitator Mechanical Seal Partner

With over thirty years of industry experience, Sakowitz provides highly reliable sealing solutions for global mixing equipment and reaction systems. We are not only the Manufacturer of Agitator Mechanical Seals, but also a long-term engineering partner for our customers.

- Rich Experience: Over 30 years of expertise in designing and manufacturing sealed systems, with a focus on the chemical, pharmaceutical, and food industries.

- Global Trust: Products have been exported to over 50 countries, serving hundreds of international brands and equipment manufacturers.

- High Precision Manufacturing: CNC processing accuracy < 2 µm, ensuring a perfect fit of the sealing end face, reducing wear and leakage.

- Customized Design: Solutions can be tailored according to the shaft diameter, pressure, and medium characteristics of the equipment.

- High-End Material Selection: Uses corrosion-resistant materials such as SS316, Hastelloy®, PTFE, and FKM to extend service life.

- Full-Scale Technical Support: Provides installation guidance, maintenance training, and rapid global delivery services.

FAQ – Common Questions About Agitator Mechanical Seals

Q1: Can Sakowitz agitator seals replace OEM brands like John Crane or EagleBurgmann?

Yes. We offer OEM replacement models compatible with mainstream brands, and can also customize and design exclusive Agitator Mechanical Seal solutions according to customer working conditions.

Q2: Are your seals suitable for vacuum or pressure reactors?

Absolutely. Sakowitz’s sealing system supports both negative pressure (vacuum) and positive pressure conditions, ensuring stable operation even under extreme reaction conditions.

Q3: What’s the average service life?

It can usually operate stably for 3 to 5 years, depending on the type of medium, rotational speed and maintenance conditions. Reasonable lubrication and cooling can significantly extend the service life of the seal.

Q4: Do you offer FDA or ATEX-certified agitator seals?

Yes. All Sakowitz stirring seals comply with international standards such as FDA, ATEX, CE, and ISO 21049, and are suitable for food, pharmaceutical, and explosion-proof working environments.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Engineering Excellence – Precision That Performs

Each Sakowit seal is designed, machined, and tested for maximum reliability and long service life — even in the toughest environments.

Proven Performance – Reliable in Every Industry

Trusted by engineers worldwide for consistent performance in chemical, slurry, and high-demand process systems.

Global Support – Fast Response, Trusted Service

Global network and responsive support ensure you get expert help when you need it — wherever you are.