Introduction: Why “Perfect Seals” Fail in Real Operation

Many mechanical seal failures are mistakenly blamed on seal quality or material selection.

In reality, a large percentage of premature seal failures are caused by shaft runout, misalignment, and excessive vibration.

Even the most advanced mechanical seal cannot survive long if the rotating system is unstable.

This article explains how shaft runout, misalignment, and vibration damage mechanical seals, the typical failure symptoms they create, and practical ways to correct these issues in real pump applications.

Shaft Runout: The Silent Seal Killer

What Is Shaft Runout?

Shaft runout is the radial or axial deviation of the shaft from its true centerline during rotation.

In simple terms, the shaft does not rotate perfectly concentrically.

How Runout Causes Seal Failure

Mechanical seal faces are designed to operate with micron-level flatness and alignment.

Excessive shaft runout causes:

-

Uneven seal face contact

-

Localized overheating

-

Face chipping or cracking

Accelerated wear of secondary seals

Even small runout values can destroy seal faces at high RPM.

Typical Symptoms

-

Polished wear marks on one side of the seal face

-

Repeated seal failures at short intervals

-

Leakage shortly after startup

How to Fix Shaft Runout

-

Measure shaft runout with a dial indicator

-

Check shaft straightness and bearing condition

-

Replace worn bearings

-

Use balanced or cartridge seals for higher tolerance

Misalignment: When the Seal Is Forced to Compensate

What Is Misalignment?

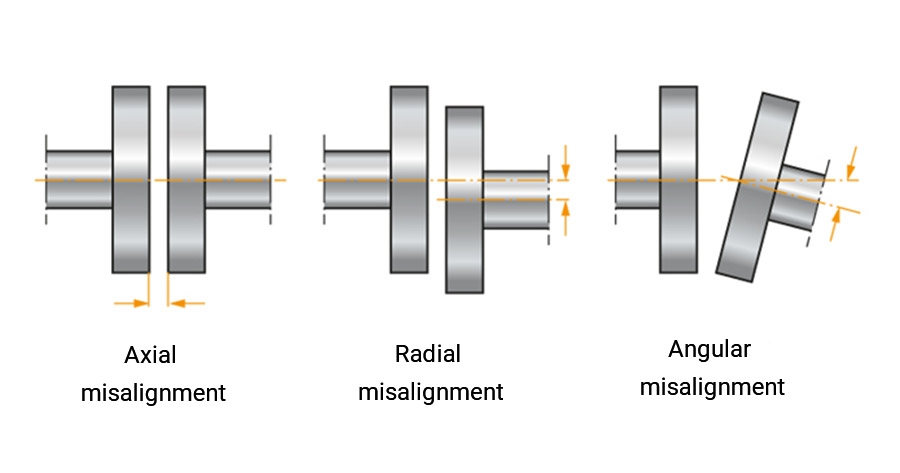

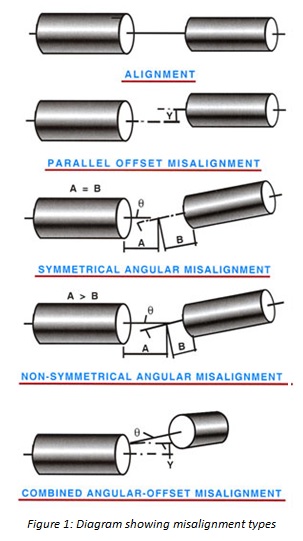

Misalignment occurs when the pump shaft and driver shaft are not collinear.

It can be:

-

Angular misalignment

-

Parallel (offset) misalignment

-

Combined misalignment

Why Misalignment Destroys Mechanical Seals

Mechanical seals are not alignment correction devices.

Misalignment forces the seal faces to constantly flex and tilt, leading to:

-

Face opening and closing cycles

-

Loss of hydrodynamic lubrication

-

Excessive heat generation

-

Secondary seal fatigue

Common Failure Signs

-

Heat checking on seal faces

-

Cracked carbon rings

-

Broken bellows or springs

How to Fix Misalignment

-

Perform laser or dial alignment

-

Check coupling condition

-

Re-align after thermal growth stabilization

-

Avoid rigid couplings in vibration-prone systems

Vibration: The Accelerator of Seal Damage

Where Does Vibration Come From?

Common vibration sources include:

-

Cavitation

-

Hydraulic imbalance

-

Bearing wear

-

Resonance

-

Poor foundation or piping stress

How Vibration Affects Mechanical Seals

Vibration does not usually cause immediate failure, but it accelerates every other failure mechanism:

-

Micro-movement of seal faces

-

Fatigue of springs and bellows

-

Loosening of drive components

-

Seal face glazing or blistering

Typical Seal Damage Patterns

-

Polished but leaking faces

-

Fractured brittle materials (ceramic, SiC)

-

Rapid elastomer hardening or cracking

How to Reduce Vibration

-

Address hydraulic conditions (avoid cavitation)

-

Improve baseplate and foundation rigidity

-

Install vibration dampers where needed

-

Consider double seals in severe vibration environments

Why These Problems Are Often Overlooked

Runout, misalignment, and vibration are system-level issues, not seal-level issues.

Replacing seals without correcting the root cause often results in:

“The seal failed again — must be a bad seal.”

In reality, the seal is only reacting to mechanical instability.

Practical Engineering Solutions That Actually Work

Design-Level Improvements

-

Use cartridge mechanical seals

-

Select flexible bellows designs

-

Choose materials with higher shock resistance (e.g. SiC or TC)

Installation & Maintenance Improvements

-

Verify shaft runout before seal installation

-

Re-align after piping is connected

-

Monitor vibration trends, not just absolute values

When to Upgrade the Seal System

-

Repeated failures despite correct sizing

-

High-speed or high-temperature operation

-

Applications with known hydraulic instability

FAQ: Mechanical Seal Failures Caused by Motion Issues

Q1: Can a better seal material solve runout problems?

No. Better materials may delay failure but cannot eliminate mechanical misalignment.

Q2: Are cartridge seals more tolerant of vibration?

Yes. Cartridge seals generally offer better alignment control and installation accuracy.

Q3: How much runout is acceptable?

Acceptable runout depends on speed and seal design, but lower is always better.

Final Thoughts: Seals Fail Because Systems Move

Mechanical seals are precision components operating in imperfect mechanical systems.

Shaft runout, misalignment, and vibration introduce dynamic forces that no seal can fully compensate for.

The most reliable seal solutions combine:

-

Correct seal selection

-

Stable rotating equipment

-

Proper installation and monitoring

Fix the system — and seal life will follow.

Call to Action (CTA)

👉 Experiencing repeated mechanical seal failures?

Share your pump speed, alignment condition, and vibration symptoms. Our technical team can help identify system-level causes and recommend more robust sealing solutions.

👉https://sakowit.com/how-operating-conditions-affect-mechanical-seal-performance-in-industrial-pumps/