Hydraulic Mechanical Seal Manufacturer

We providing high-pressure, wear-resistant and zero-leakage sealing solutions for hydraulic pumps, hydraulic motors and hydraulic systems worldwide.

– Sakowit high-performance Hydraulic Mechanical Seals

Understanding Hydraulic Mechanical Seals and Their Function

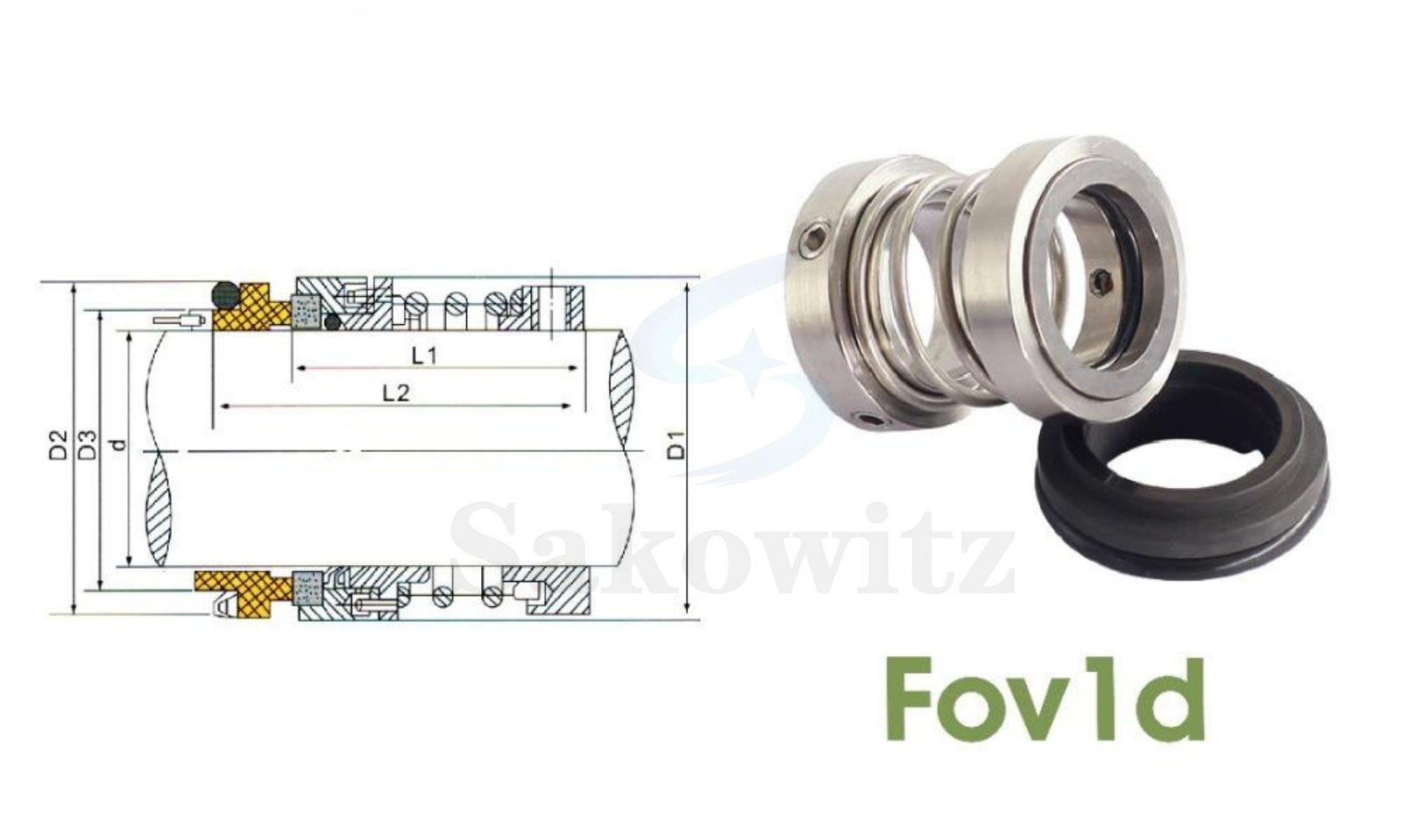

A hydraulic mechanical seal is a high-precision sealing component installed between the pump shaft and the housing. Its main function is to prevent the leakage of hydraulic oil or working medium under high pressure. Through the close contact of the end faces of the moving ring and the stationary ring, the mechanical seal can form a very thin liquid film. This not only lubricates the sealing end faces but also prevents the leakage of the liquid, thereby maintaining the system pressure and efficiency.

Compared to traditional packing seals or O-rings, hydraulic mechanical seals offer higher sealing grades, lower friction losses and longer service life. In practical applications, they can effectively reduce the energy consumption of hydraulic systems, lower maintenance costs, and enhance the overall operational safety and cleanliness.

Why Reliable Mechanical Seals Are Essential for Hydraulic Systems

The hydraulic system operates under high pressure and high temperature conditions. Any minor leakage could lead to a decrease in pressure, contamination of the oil, or system failure. The mechanical seal can form a stable sealing interface between the pump shaft and the housing, effectively preventing the leakage of hydraulic oil and maintaining the system pressure and efficiency.

Compared to traditional packing or lip seals, mechanical seals can withstand higher pressure (up to 25–80 bar) and temperature fluctuations, while also having lower friction loss and a longer service life. This not only significantly reduces energy consumption and maintenance frequency, but also prevents oil leakage from causing environmental pollution and equipment damage.

Contact Our Mechanical Seal Specialists for Questions

Contact us, and our professional Sakowit team can help you find the most suitable mechanical seal to enhance the safety of your project.

Sakowit Engineering Solutions for Hydraulic Mechanical Seals

Sakowitz is renowned for its engineering precision and reliable performance, and is dedicated to providing high-pressure sealing and long-lasting operation support for various hydraulic equipment.

Broadly Applicable Types of Hydraulic Equipment

Suitable for gear pumps, piston pumps, vane pumps and hydraulic motors. It can meet the fluid power requirements of various industries and ensure the equipment maintains a stable seal during high-pressure circulation.

High-performance Sealing Material Combinations

The dynamic ring is made of SiC / WC / Carbon (silicon carbide, tungsten carbide, carbon graphite). These materials have excellent wear resistance and thermal conductivity, which can effectively prevent overheating at the end face and failure due to wear.

Elastomers are compatible with various working conditions

Use high-quality elastomer materials such as NBR, FKM, PTFE, and EPDM. They are suitable for different hydraulic oils and temperature ranges, ensuring that the sealing performance remains intact even in complex chemical media.

Structural metals possess high corrosion resistance

The metal components are made of stainless steel materials such as SS304, SS316, and Duplex. Even when used in water-containing or corrosive oil environments for a long time, they still maintain structural strength and stability.

Compliant with international engineering standards

All products are designed and tested in accordance with the standards of API 682 / ISO 21049 / CE. They have undergone rigorous pressure, temperature and life cycle tests to ensure that each seal meets international requirements.

Outstanding performance range and reliability

The maximum pressure-bearing capacity can reach 80 bar, the temperature range is -20°C to +200°C, the linear speed can reach up to 25 m/s, and it still maintains zero leakage performance under extreme conditions.

Technical Specifications of Hydraulic Mechanical Seals

Sakowit hydraulic mechanical seals are specially designed for high-pressure hydraulic systems and can maintain stable sealing performance in high-temperature, strong fluid impact and contaminated media. All products have undergone strict testing to ensure reliability and service life under different working conditions.

| Parameter | Range / Specification | Description / Engineering Notes |

|---|---|---|

| Pressure | Up to 80 bar | Designed for high-pressure hydraulic circuits and heavy-duty pumps. |

| Temperature | -20°C to +200°C | Suitable for continuous operation under varying temperature conditions. |

| Speed | Up to 25 m/s | Supports high-speed pump shafts with minimal wear. |

| Face Materials | SiC / Carbon / WC | High hardness materials for excellent wear and heat resistance. |

| Elastomers | NBR / FKM / EPDM / PTFE | Compatible with hydraulic oils, synthetic fluids, and aggressive chemicals. |

| Metals | SS304 / SS316 / Duplex | Corrosion-resistant metals ensure mechanical strength under stress. |

| Standards | API 682 / ISO 21049 / CE / RoHS | Fully compliant with international hydraulic sealing standards. |

Key Industries and Applications of Hydraulic Mechanical Seals

Sakowit hydraulic mechanical seals are widely used in high-pressure hydraulic systems and industrial equipment. They maintain stable sealing performance under conditions of high temperature, high speed and containing contaminated media. Provide long-term reliable operation guarantees for global engineering equipment and energy systems.

For high-pressure oil transmission and circulation systems. The sealing structure ensures zero leakage and stable pressure during prolonged operation, thereby reducing system energy consumption.

Applicable to excavators, tractors and hydraulic control accessories. Wear-resistant materials effectively resist contamination from silt, dust and hydraulic fluid.

Widely employed in injection moulding machines, presses and conveyor systems. The sealing system enhances mechanical efficiency and reduces downtime for maintenance.

Suitable for hydraulic drilling and mining hydraulic systems. Withstands high-pressure impacts and abrasion from particulate media, ensuring continuous operation.

For hydraulic winches, stabilisers and rudder systems. Corrosion-resistant alloy materials ensure stable sealing in seawater and high-humidity environments.

Suitable for hydraulic systems conveying corrosive or high-temperature fluids. Utilises materials such as FKM, PTFE, and Hastelloy to ensure chemical stability and seal integrity.

Why Global Engineers Trust Sakowitz Hydraulic Mechanical Seals

With over 30 years of sealing engineering experience and a global service network, Sakowitz has become a reliable manufacturer and technical partner in the field of hydraulic sealing. Our products are renowned for their high precision processing, international standard certification and excellent durability, and they operate stably in industrial and energy projects across more than 50 countries worldwide.

Extensive engineering experience (over 30 years of professional accumulation)

Sakowit has over thirty years of experience in the design and manufacturing of hydraulic mechanical seals, providing reliable sealing solutions for global OEM manufacturers and maintenance projects.

Global Application Verification (Installed Units in Over 50 Countries)

More than 15,000 sealed systems are currently in operation around the world, covering hydraulic pumps, hydraulic motors, construction machinery and energy equipment.

Precise Manufacturing Process (CNC processing accuracy < 2 μm)

All the seals are precisely processed by CNC technology, with the end face flatness controlled at less than 2 micrometers, ensuring zero leakage and low wear.

High-performance Material Certification (Dual Assurance of Pressure Resistance and Corrosion Resistance)

Using SS316, Duplex, Hastelloy® metals and FKM, PTFE elastomer materials, it features outstanding corrosion resistance and high-pressure tolerance.

Flexible OEM Replacement and Customization Solutions

The exclusive sealing structure can be customized according to the size of the customer’s hydraulic system and the medium. At the same time, we also offer OEM alternative models from mainstream brands.

Fast Technical Response and Global Service Support

Sakowit offers technical consultation and after-sales support worldwide, ensuring that customers receive timely guidance during the installation, commissioning and maintenance stages.

Frequently Asked Questions about Hydraulic Mechanical Seals

Q1: Can Sakowitz seals replace OEM hydraulic pump seals?

Certainly. We offer standard replacement models (Direct-Fit) and can design bespoke sealing solutions tailored to the customer’s equipment configuration and operating conditions. Whether for hydraulic pumps, hydraulic motors, or power units, we ensure perfect compatibility.

Q2: What is the expected service life of Sakowitz seals?

Under normal operating conditions, the service life is typically 2–5 years. This duration depends on the working pressure, hydraulic oil quality, and maintenance frequency. Experimental verification indicates that Sakowitz seals exhibit a service life approximately 40–60% longer than conventional seals.

Q3: Do you offer seals for biodegradable or fire-resistant hydraulic fluids?

Sakowit employs highly compatible materials such as FKM and PTFE, meeting the chemical compatibility requirements for a wide range of hydraulic fluids, including environmentally friendly, bio-based and fire-resistant hydraulic fluids.

Q4: Are Sakowit seals suitable for marine and mining hydraulics?

Fully applicable. Constructed from stainless steel, duplex steel and Hastelloy metal structures, it resists corrosion from seawater, silt and corrosive oils. Demonstrates exceptional durability in marine engineering, mining equipment and high-humidity environments.

Submit a Quick Quote

Why Us is Trusted by 1000+ Clients

Engineering Excellence – Precision That Performs

Each Sakowit seal is designed, machined, and tested for maximum reliability and long service life — even in the toughest environments.

Proven Performance – Reliable in Every Industry

Trusted by engineers worldwide for consistent performance in chemical, slurry, and high-demand process systems.

Global Support – Fast Response, Trusted Service

Global network and responsive support ensure you get expert help when you need it — wherever you are.