Mechanical seals play an indispensable role in modern industries, ensuring the efficiency and safety of machinery across a variety of applications. From chemical processing to oil and gas, power generation, and marine transportation, these essential components are the backbone of critical equipment that operates under high-pressure and high-temperature environments.

As industrial processes advance, the global demand for high-quality mechanical seals continues to rise. This article explores the evolving market for mechanical seals, highlighting customer types and the specific needs that define their purchasing decisions.

Understanding Mechanical Seals and Their Importance

Mechanical seals are devices used to prevent leakage between two joining parts, typically in pumps, compressors, and rotating machinery. They are crucial in preventing fluid or gas leaks, reducing environmental risks, and extending the lifespan of expensive equipment.

Key features of mechanical seals include:

- High durability: Able to withstand extreme temperatures, pressures, and corrosive environments.

- Energy efficiency: Reduces friction and energy losses.

- Cost-effectiveness: Prolongs equipment life and minimizes downtime, making them an investment rather than an expense.

Key Market Demand Drivers

The increasing adoption of mechanical seals is driven by several factors:

- Environmental Regulations: Industries are under pressure to adopt eco-friendly practices, reducing emissions and minimizing waste. High-performance seals help achieve these goals by preventing leakage and ensuring compliance.

- Industrial Growth: Emerging markets in Asia, the Middle East, and South America are driving growth in heavy industries, which demand reliable sealing solutions.

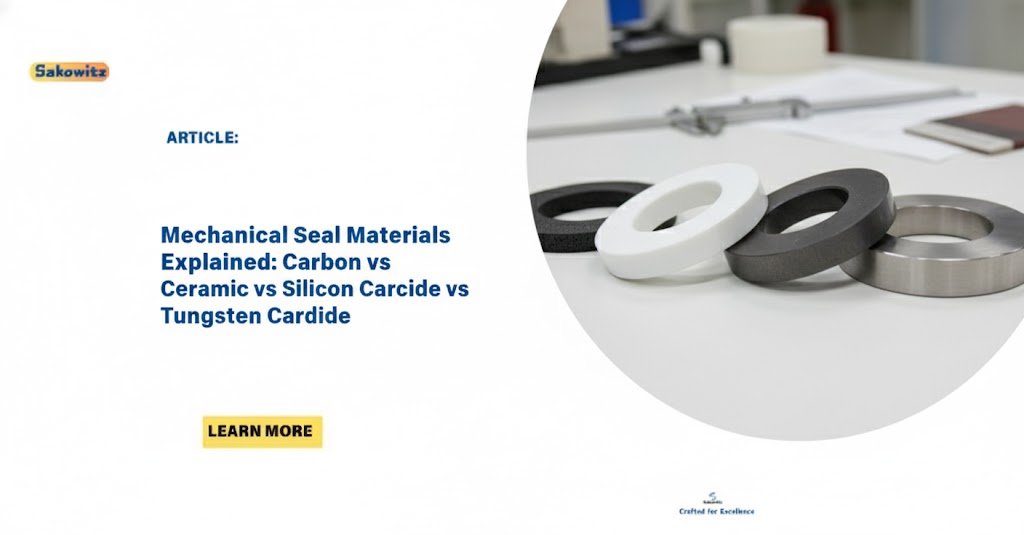

- Technological Advancements: The development of advanced materials, such as carbon, ceramics, and high-grade alloys, has enhanced seal performance, fueling demand in industries with extreme operating conditions.

- Preventative Maintenance Trends: Companies are increasingly prioritizing preventative maintenance to reduce unplanned downtime, further boosting the need for durable and reliable seals.

Who Are the Key Buyers of Mechanical Seals?

Understanding customer types is critical to serving their needs effectively. Below are the main types of customers for mechanical seals:

Industrial Manufacturers and End-Users

These include large-scale production facilities in industries such as:

- Chemical processing: Requires corrosion-resistant seals to handle aggressive chemicals.

- Oil and gas: Demands seals that perform under extreme pressure and temperature.

- Power generation: Needs high-performance seals for turbines, pumps, and cooling systems.

- Marine and shipping: Relies on seals to handle seawater exposure and reduce maintenance in remote operations.

These customers prioritize reliability, durability, and energy efficiency, often seeking tailored solutions for their specific applications.

Equipment Maintenance and Repair Companies

Maintenance service providers often purchase mechanical seals as part of their repair and replacement services for clients. Their primary concerns include:

- Quick access to standard seals to minimize downtime.

- Consistent quality and performance to satisfy their clients’ expectations.

- Access to technical support for specialized applications.

Distributors and Resellers

Hardware distributors and spare parts resellers serve as intermediaries, offering mechanical seals to small and medium-sized enterprises (SMEs) or maintenance teams. These businesses value:

- Competitive pricing for bulk orders.

- Diverse inventory to meet varying customer demands.

- Reliable supply chains for timely delivery.

How to Meet Market Needs Effectively

As the market evolves, customers are looking for suppliers who can provide:

- Customization: Industries increasingly require seals designed for specific operating conditions, such as high-viscosity liquids, extreme temperatures, or unique equipment specifications. Offering tailored solutions can be a major differentiator.

- Premium Quality Materials: Ensuring that seals are manufactured using the latest material technologies (e.g., ceramics, tungsten carbide) can position your products as high-performance and long-lasting.

- Global Logistics Support: Customers expect faster delivery times, especially for urgent maintenance needs. A streamlined logistics process is essential for building trust.

- Comprehensive Support: Providing technical consultation, training, and after-sales support will establish you as a reliable partner, not just a supplier.

Why Choose Us?

At Sakowitz, we specialize in delivering premium-quality mechanical seals tailored to meet the diverse needs of global industries. With years of expertise and a commitment to innovation, we strive to provide solutions that enhance efficiency, reduce maintenance costs, and protect the environment.

Whether you are an industrial manufacturer, a maintenance service provider, or a distributor, we are here to support your business with reliable products and outstanding customer service. Let us help you achieve operational excellence.

Conclusion

The mechanical seal market is poised for continued growth, driven by industrial expansion, environmental concerns, and advancements in technology. By understanding the specific needs of different customer groups and providing solutions that address their pain points, suppliers can tap into this lucrative market and build long-lasting relationships.

Explore our range of mechanical seals today and see how we can help your business thrive.

Does this align with your expectations for the first article? Let me know if you’d like any adjustments!