In high-temperature industrial environments, choosing the right sealing material can significantly affect equipment reliability, maintenance cost, and operational safety. Two of the most widely discussed materials for heat-resistant applications are FKM (commonly known by the brand name Viton™) and FFKM (Perfluoroelastomer). But which one is more suitable for extreme temperature conditions?

1. Overview of FKM and FFKM

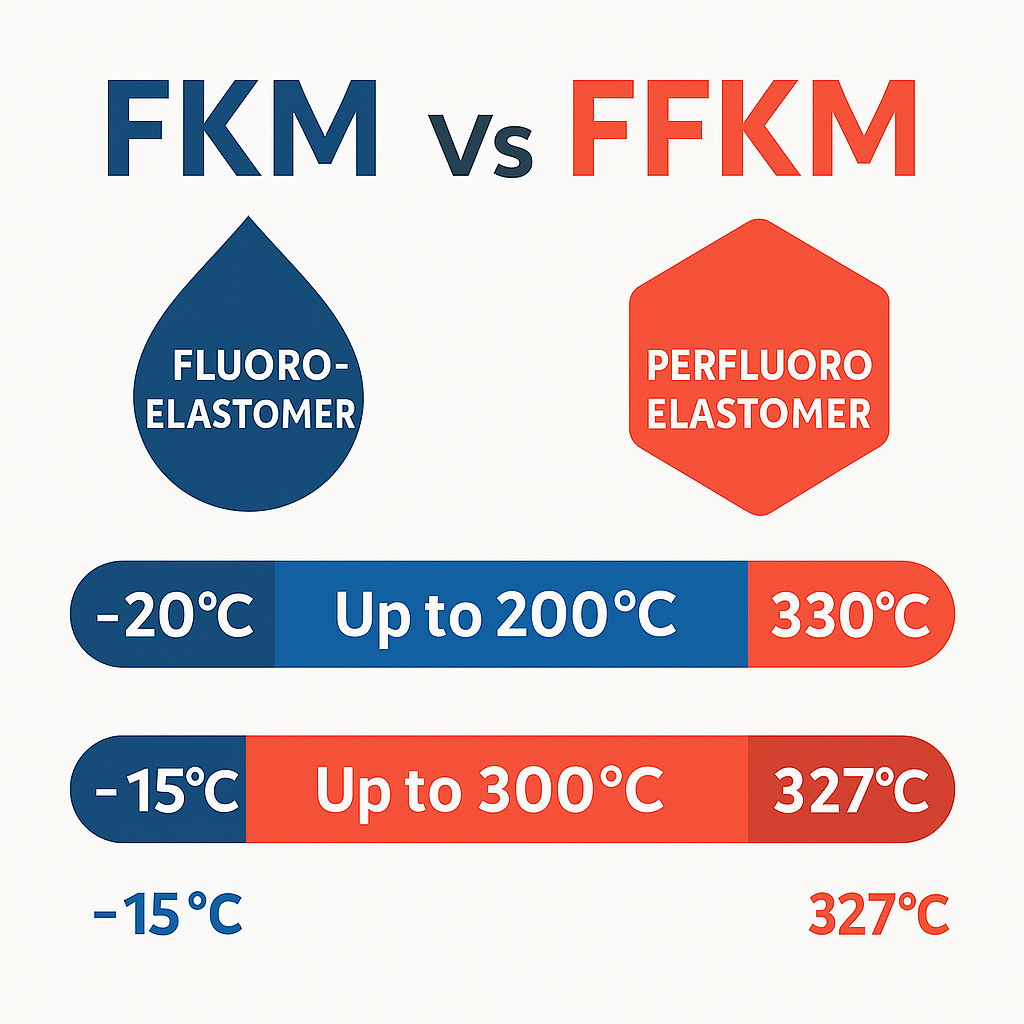

– FKM (Fluoroelastomer): Known for its excellent resistance to high temperature, oil, and chemicals. Typically used in automotive, chemical processing, and pump sealing systems. Temperature range: –20°C to 200°C, up to 230°C in short bursts.

– FFKM (Perfluoroelastomer): A premium-grade sealing material offering exceptional thermal and chemical resistance. Often used in semiconductor, aerospace, and pharmaceutical industries. Can withstand temperatures from –20°C to over 300°C.

2. Temperature Resistance Comparison

| Property | FKM (Viton) | FFKM |

| Continuous Temp. | Up to 200°C | Up to 300°C+ |

| Short-Term Peaks | ~230°C | ~327°C |

| Thermal Degradation | Moderate above 200°C | Excellent thermal stability |

Conclusion: If your application runs near or above 250°C, FFKM is the better choice.

3. Chemical Compatibility

Both materials offer chemical resistance, but FFKM outperforms FKM in ultra-aggressive environments such as:

– Organic acids

– Ketones

– Ethers

– Superheated steam

For most industrial pump seals and general fluid handling, FKM is sufficient and cost-effective. For pharmaceutical or semiconductor-grade sealing, FFKM is preferred.

4. Cost Consideration

– FKM: More affordable; suitable for standard industrial applications.

– FFKM: 5 to 10 times more expensive; best reserved for mission-critical systems.

5. Applications & Industry Use

| Application | Recommended Material |

| Water pump seals | FKM (Cost-efficient) |

| Chemical agitator seals | FKM / FFKM (depends on fluid) |

| Semiconductor processing | FFKM |

| Aerospace & high-temp gas | FFKM |

Related Product: Explore our Pump Seals → https://sakowit.com/mechanical-seal-landing-page/

6. FAQ: FKM vs FFKM

Q: Is FFKM always better than FKM?

A: Not necessarily. FFKM performs better at high temperatures and in harsh chemicals, but for most standard industrial applications, FKM provides an ideal balance between cost and performance.

- Q: Can I use FKM in pharmaceutical sealing?

A: FKM can be used, but if you’re handling aggressive solvents or require ultra-clean environments, FFKM is recommended.

- Q: What’s the main downside of FFKM?

A: Cost. It is significantly more expensive, and over-specifying it can impact your budget without delivering practical benefits.

- Q: Which is more durable over time?

A: FFKM resists chemical aging and thermal breakdown better than FKM, especially in high-temperature continuous use.

7. External References

• DuPont Viton Material Guide: https://www.dupont.com/products/viton.html

• FFKM Technology Overview by Parker: https://www.parker.com/portal/site/PARKER/menuitem

Need Help Choosing the Right Material?

Contact our technical team for expert advice and get matched with the perfect seal for your application.

Get a Quote or Free Consultation → https://sakowit.com/mechanical-seal-landing-page/