Selecting the right mechanical seal for your industrial pump is critical to ensuring long-term performance, safety, and efficiency. With various types, materials, and application conditions, the selection process can be overwhelming. This guide breaks down the key points to help you make the ideal choice for your pump system.

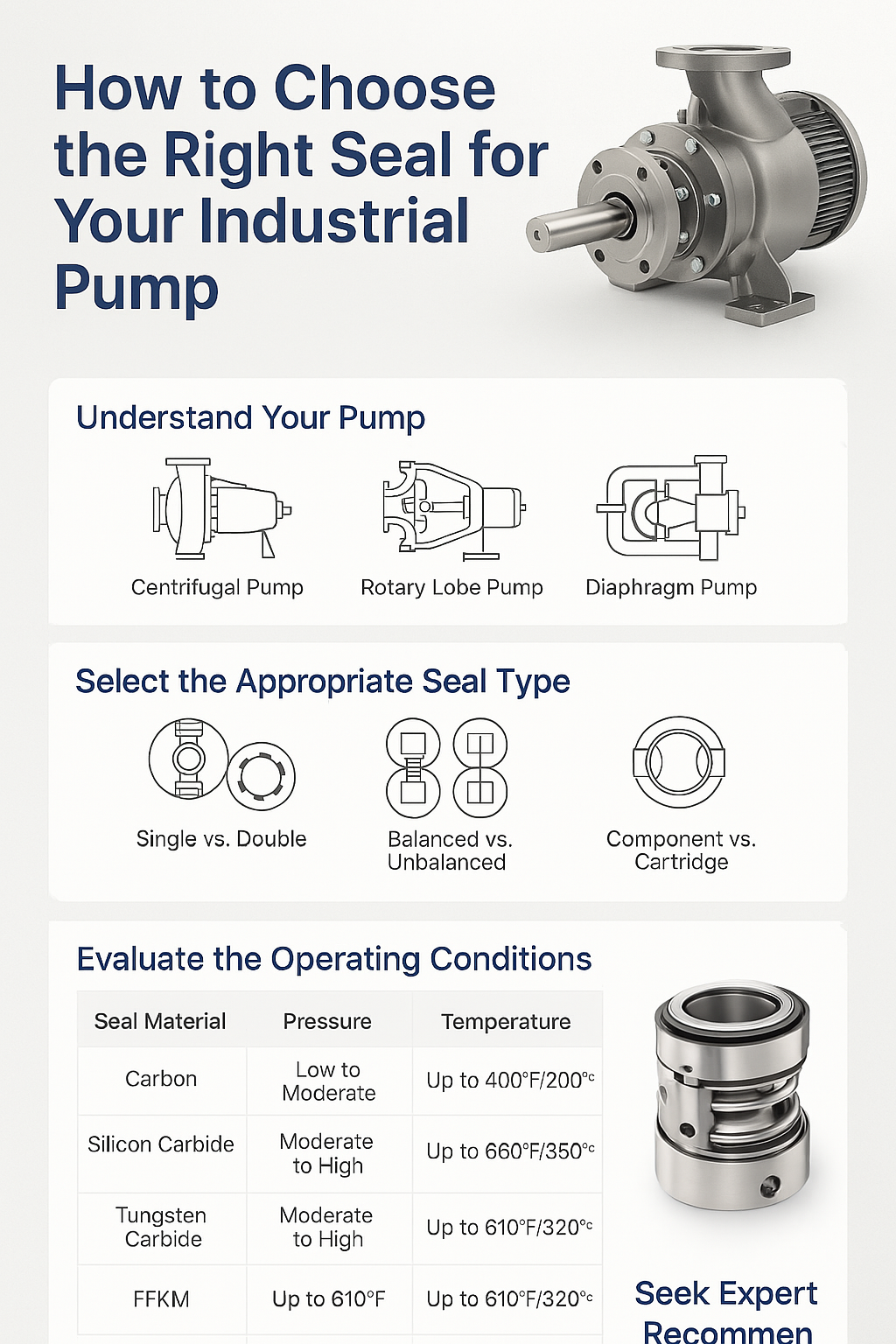

1. Understand Your Pump and Operating Conditions

Before choosing a seal, gather the following information:

- Pump Type: Centrifugal, positive displacement, submersible, etc. (Learn about different pump types)

- Fluid Type: Is it corrosive, abrasive, or volatile?

- Temperature & Pressure: Minimum and maximum operating ranges.

- Speed: Shaft rotation speed (RPM).

- Installation Orientation: Horizontal or vertical?

Understanding these variables is essential to selecting the appropriate seal type and materials.

2. Choose the Appropriate Seal Type

Here are several common types of mechanical seals, each suitable for specific conditions:

- Single Seal: Cost-effective, for clean fluids and moderate conditions.

- Double Seal: Offers extra safety, ideal for hazardous or abrasive fluids.

- Cartridge Seal: Pre-assembled, easy to install, reduces installation errors.

- Balanced Seal: Handles higher pressure and generates less heat.

- Unbalanced Seal: Suitable for low-pressure, clean applications.

- Pusher vs. Non-pusher (Bellows): Bellows work better for high-temperature or aggressive media.

Learn more about our cartridge mechanical seals for industrial pumps.

3. Select the Right Seal Materials

Seal material compatibility is critical for performance and longevity:

- Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC), Ceramic

- Elastomers: NBR, Viton, EPDM, PTFE, FFKM

- Metal Components: Stainless Steel 304/316, Hastelloy, Alloy 20

For example, SiC and TC are great for abrasive or corrosive fluids, while FFKM and PTFE are ideal for high-temperature or aggressive chemicals.

Refer to chemical compatibility charts for better material selection.

4. Consider Industry Standards and Certifications

Some industries may require compliance with specific standards:

- API 682 (Oil & Gas) – API Seal Standard Info

- FDA/USP Class VI (Pharmaceutical/Food)

- EN 12756 / DIN 24960 (General Industry)

Choosing certified seals ensures safety and regulatory compliance.

Explore our seals used in oil and gas applications.

5. Factor in Maintenance and Total Cost of Ownership

- Ease of Installation: Cartridge seals save time and reduce errors.

- Durability: Premium materials last longer despite higher upfront costs.

- Spare Parts Availability: Select seals with accessible replacement parts.

Investing in quality seals often lowers total lifecycle costs significantly.

Visit our spare parts support section to request parts or assistance.

6. Consult with a Trusted Supplier

If you’re still unsure, consult a professional supplier. Sakowitz offers:

- Custom designs for challenging fluids

- Multiple material options tailored to your industry

- Fast technical support and global delivery service

Explore our full range of pump mechanical seals

Need help choosing? Contact our technical support

Final Thoughts

Choosing the right mechanical seal isn’t simple. Understanding your equipment, media properties, and process conditions is crucial. Every detail—from structure to cost—affects performance and reliability.

Still unsure which seal to choose? Contact Sakowitz for expert advice and a personalized quote.

Frequently Asked Questions (FAQ)

Q1: What’s the difference between single and double mechanical seals?

A: Single seals are suitable for clean and moderate applications, while double seals provide additional containment for hazardous or abrasive fluids.

Q2: How do I know which seal material is best for my fluid?

A: Consider chemical compatibility, temperature, and abrasiveness. For example, PTFE and FFKM are great for aggressive chemicals, while SiC or TC handle abrasive slurries well.

Q3: Do I need a balanced or unbalanced seal?

A: Use a balanced seal for high-pressure applications. Unbalanced seals are more cost-effective for low-pressure, clean fluid environments.

Q4: Can I replace my current seal with a cartridge seal?

A: In most cases, yes. Cartridge seals are designed for easy installation and retrofit into existing systems.

Learn more: Cartridge Seal Benefits

Q5: How often should I replace mechanical seals?

A: It depends on operating conditions, but typically every 1–3 years. Predictive maintenance or seal monitoring can help extend lifespan.

Q6: Does Sakowitz offer custom seals?

A: Yes. We provide tailored solutions based on your application, media, temperature, and pressure needs.

Browse our custom seal services